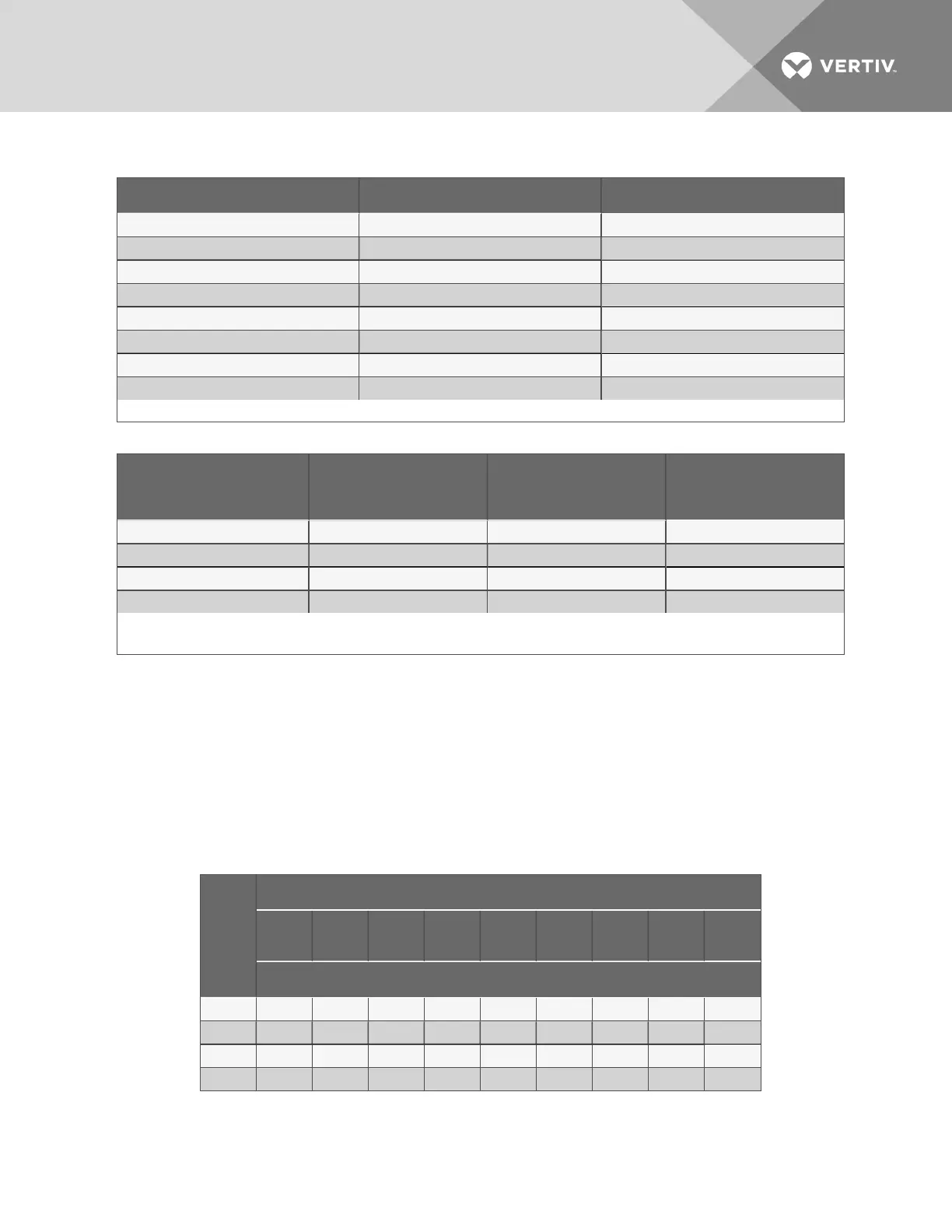

Line Size, O.D., in. Liquid Line Hot Gas Line

3/8 3.2 (1.4) —

1/2 5.9 (2.7) 0.7 (0.3)

5/8 9.6 (4.3) 1.1 (0.5)

3/4 14.3 (6.4) 1.6 (0.7)

7/8 19.8 (8.8) 2.3 (1.0)

1-1/8 33.8 (15.1) 3.9 (1.7)

1-3/8 51.5 (23.0) 5.9 (2.6)

1-5/8 — 8.4 (3.7)

Source: DPN003099, Rev. 0

Table 5.6 Interconnecting piping refrigerant charge for R-410A, lbper 100ft(kgper30m)

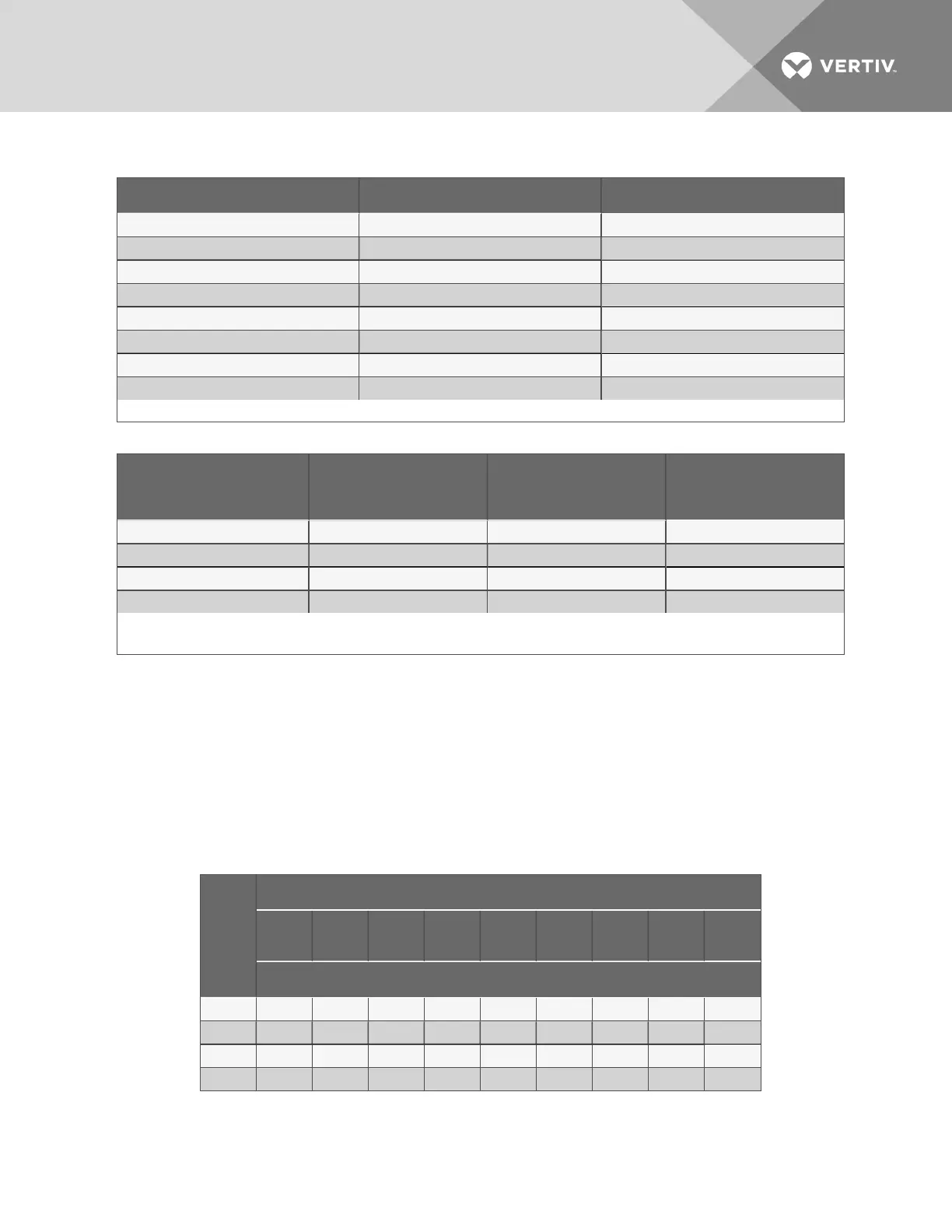

CondenserModel

Condensers without

receivers, lb (kG)

Condensers

withLiebert Lee-Temp

1

receiver, lb (kG)

Condensers without Liebert

Lee-Temp

1

receiver, lb (kG)

MCS028 2.5 (1.2) 21.7 (9.8) 11.0 (5.0)

MCM040 3.5 (1.6) 22.7 (10.3) 12.0 (5.4)

MCL055 5.0 (2.3) 24.2 (11.0) 13.5 (6.1)

MCM080 8.5 (3.8) 39.8 (18.1) 17.0 (7.7)

1. Condenser charge includes receiver.

Source: DPN002411 Rev. 8

Table 5.7 Condenser refrigerant charge approximateR-410A per circuit including receiver

Additional Oil Requirements forScrollandDigital-scrollCompressors

See Table 5.8 below, for the amount required for various system charge levels.

After the system has been fully charged with refrigerant, use a hand pump to add the additional oil at the

suction side of the system while the system is running.

The amount of oil added by field service must be recorded on the tag marked “Oil Added Field Service

Record,” attached to each compressor. The date of oil addition must be included as well.

Model

Refrigerant System Charge Per Circuit, lb (kg) *

<40

(18.1)

40

(18.1)

50

(22.7)

60

(27.2)

70

(31.8)

80

(36.3)

90

(40.8)

100

(45.4)

110

(49.9)

Additional Oil Required Per Circuit, oz (ml)

PX011 0 4 (120) 6 (180) 8 (240) 10 (300) 12 (360) 14 (410) 16 (480) 18 (530)

PX018 0 6 (180) 9 (270) 12 (360) 15 (440) 18 (530) 21 (620) 24 (720) 27 (800)

PX023 0 6 (180) 9 (270) 12 (360) 15 (440) 18 (530) 21 (620) 24 (720) 27 (800)

PX029 0 6 (180) 9 (270) 12 (360) 15 (440) 18 (530) 21 (620) 24 (720) 27 (800)

Table 5.8 Additional oil required per refrigerant charge

Vertiv | Liebert® PDX™ and PCW™ Installer/User Guide | 37

Loading...

Loading...