3

Level-Up®

Aftermarket Manual

www.lippertcomponents.com (574) 537-8900 Rev: 09.15 - Level-Up® Aftermarket Manual

1. Use the checklist on the previous page to provide a guideline for

setting up the Level Up install.

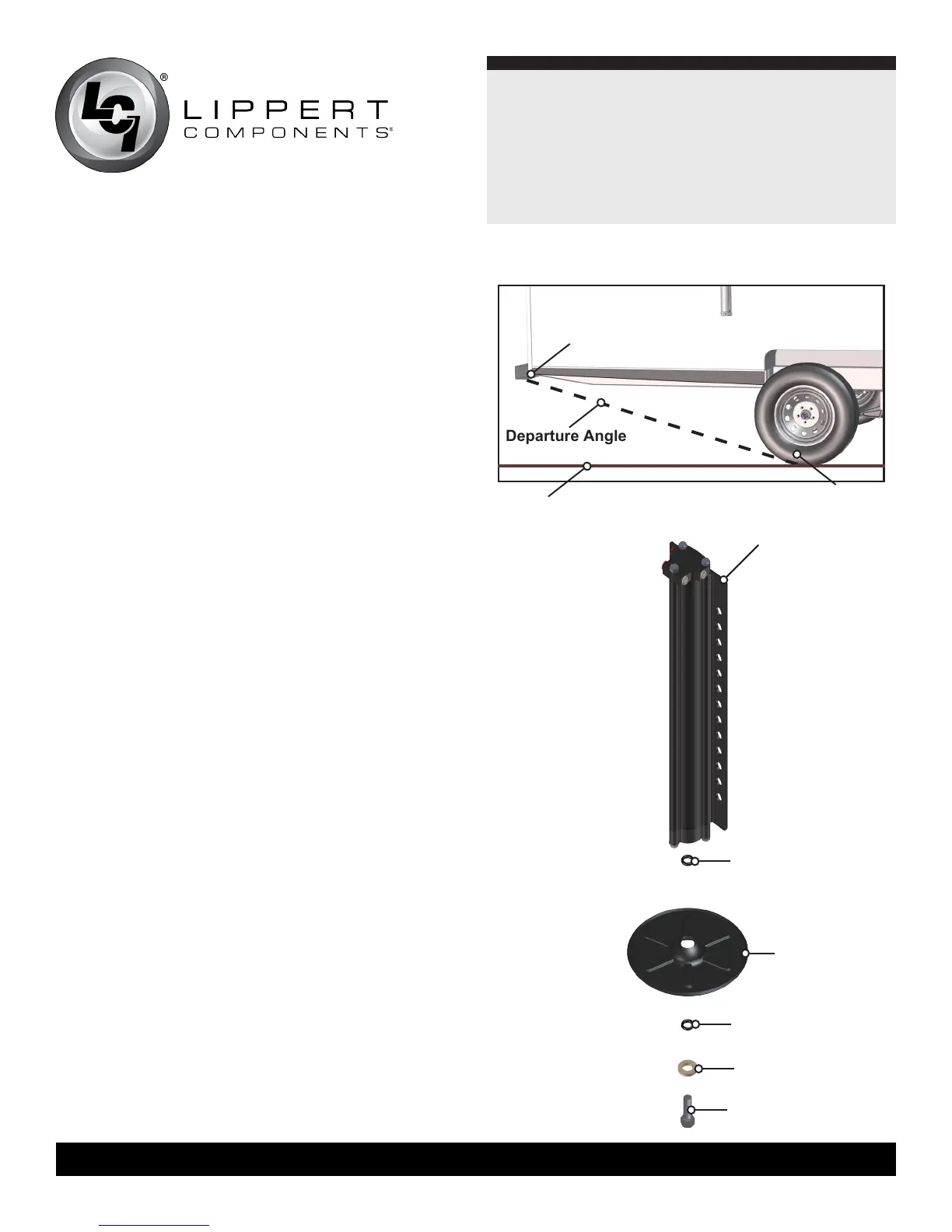

2. Determine how and where the leveling jack brackets will be

welded to the frame of the coach.

NOTE: The rear Level Up jacks should be mounted approximately

behind the rear tires, within the plane of the departure angle

(Fig. 1), and aligned with each other. The front Level Up

jacks should be mounted approximately 1 foot in front of the

front tires. Front jacks can be offset up to 24 inches to clear

obstructions, i.e. entry steps. Determine the location of the

current power unit (if one is already on the coach) or where the

new power unit and valve manifolds will be mounted.

3.Checkforanyobstructionsthatwillrequiremodicationofthe

brackets prior to welding (slide-out cross shafts, outriggers, or

manual override connections for slide-outs).

4. Extend all slide-out rooms. This will clear space for welding the

Level Up brackets by moving the fender skirts out of the way.

5. Drop the underbelly from the outside edge of the unit. Start on

the side closest to where the pump will be located and un-bolt

the underbelly from the front of the unit to approximately 2 feet

beyond the rear tire. On the opposite side of the unit, un-bolt

the underbelly from approximately 2 feet behind the rear tire

to approximately 2 feet in front of the front tire. Do not remove

any bolts from the center of the underbelly. Do not drop the

entire underbelly. Attaching and aligning the entire underbelly

will be more difficult than working around the underbelly.

6. Locate and move any wires, hoses, etc. that could be damaged

while welding the jack brackets to the frame. Check both

inside and outside of the frame. Shields made of metal or

wood can be used to push wires and hoses away from the

frame area where welding is to be done.

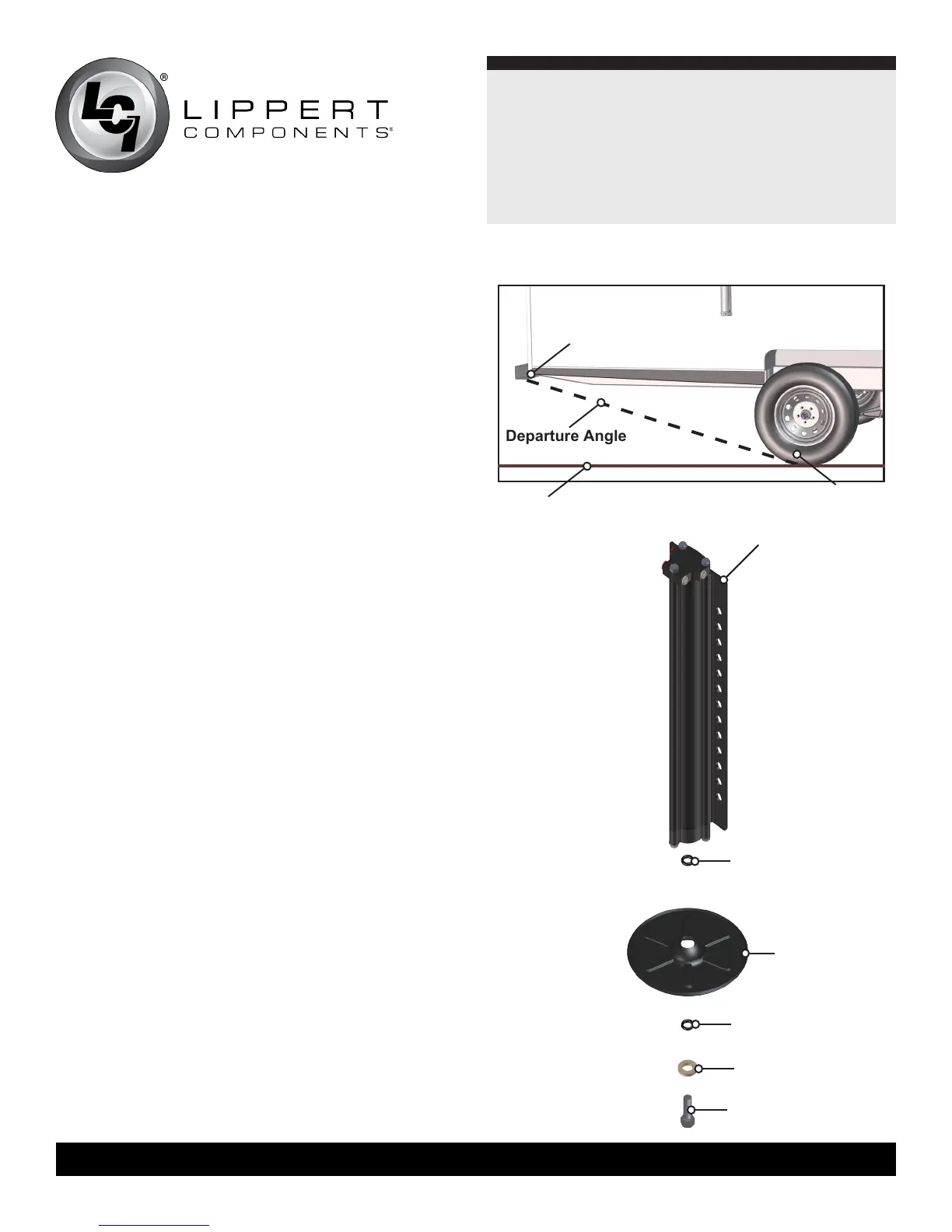

7. Bolt the footpads to the jacks and torque to 132 ft/lbs. Make

sure to use Loctite® on the footpad bolts. See bolt in (Fig. 2)

assembly for reference.

NOTE: Do not try to remove the bolt once it is tightened.

Removing the bolt could result in damage to the cylinder.

Leveling Jack

Departure Angle

Ground

Rear Tire

O-Ring

Foot Pad

O-Ring

Washer

Bolt

Fig.1

Fig.2

Lowest Point on

Rear of Coach

Loading...

Loading...