39

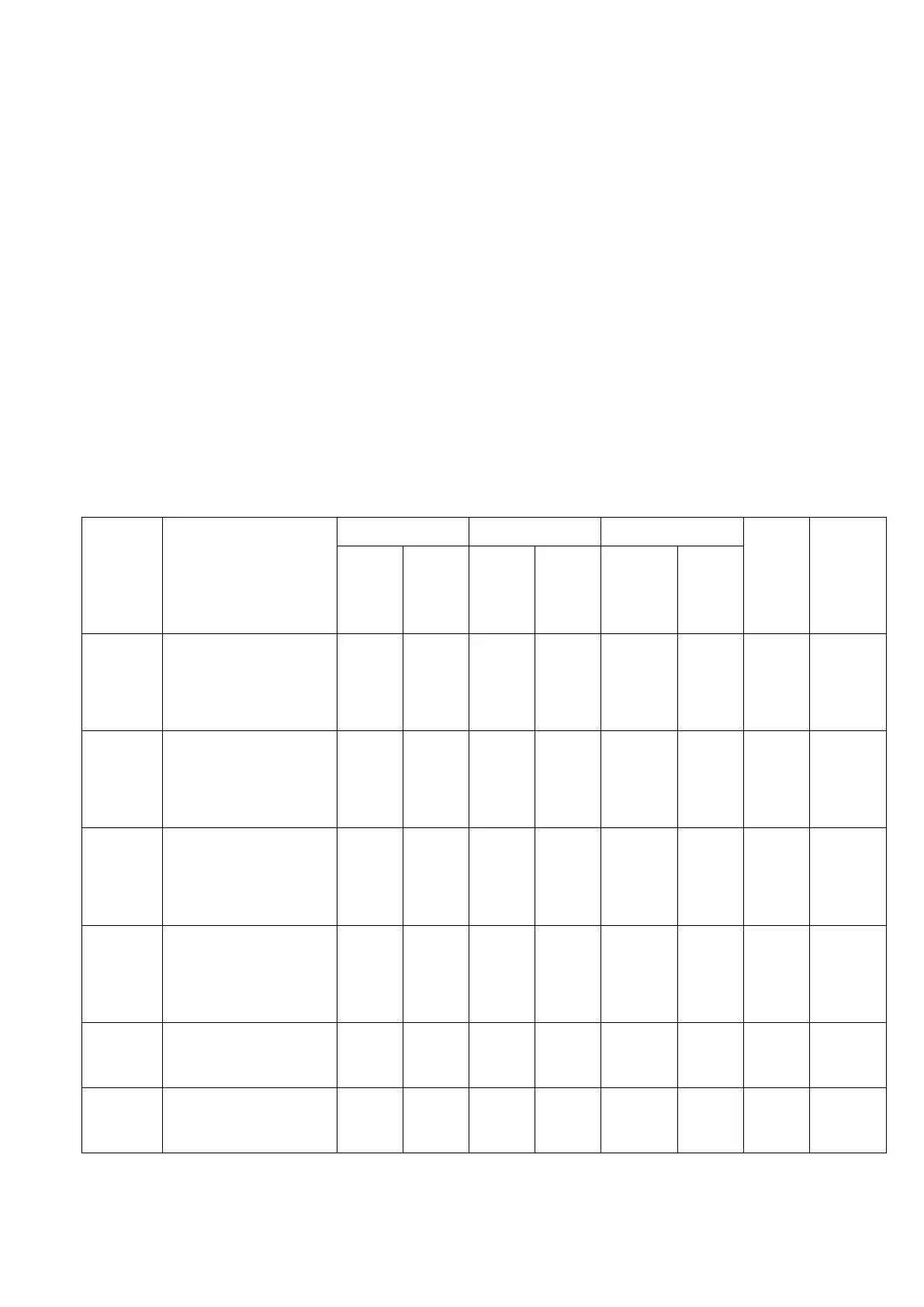

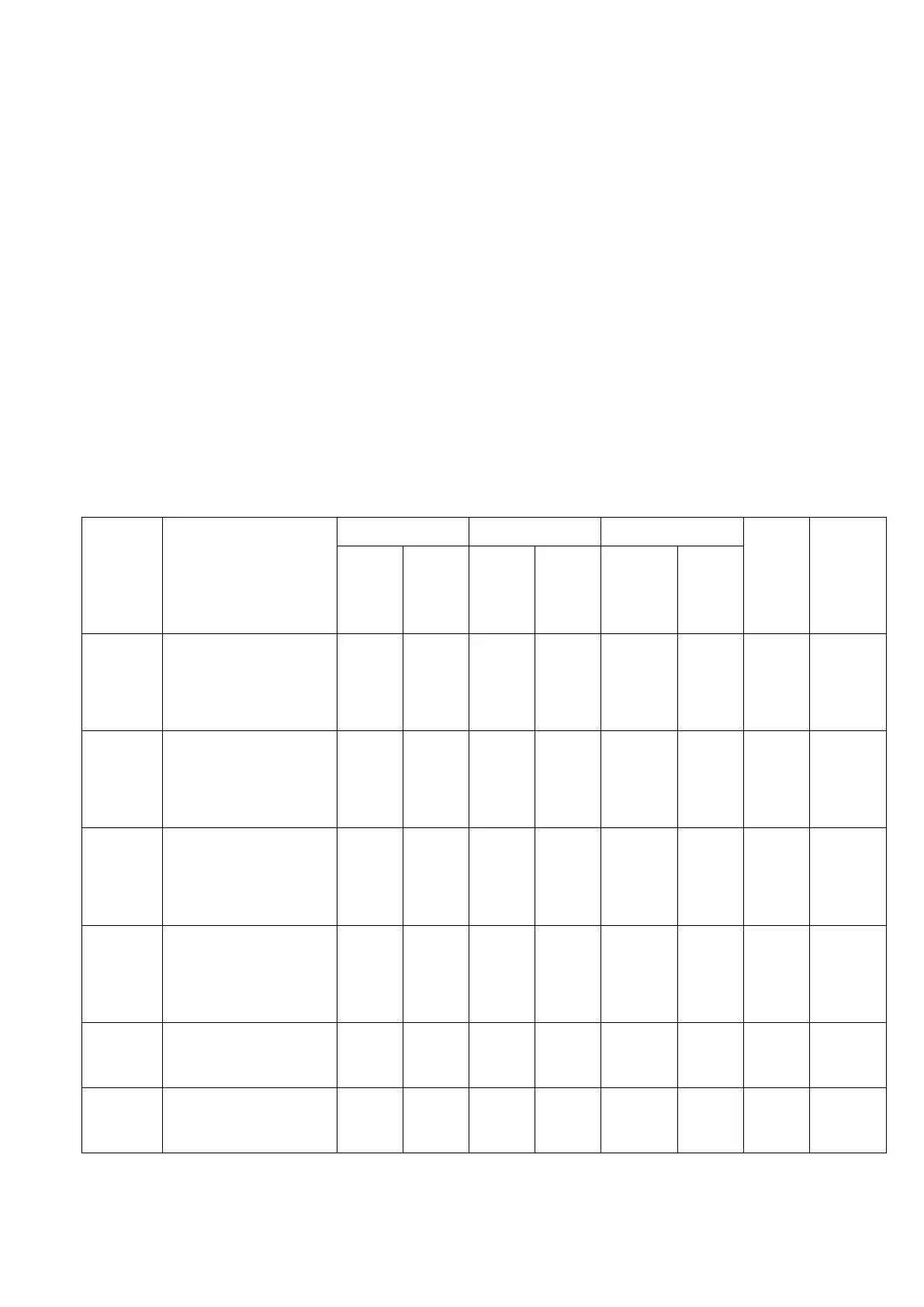

4.2.3 Main Circuit Cable Size and Tightening Torque

Select the cables and crimp terminals according to Table 4.2.2.

1. The recommended cable size is based on Normal Duty Mode using 75 °C 600 V vinyl-sheathed

cable with ambient temperature tolerance below 40 °C and wiring distance less than 100 m.

2. Terminal +1, +2, B1, B2 are only for connecting DC reactor and braking resistor options. Do not

connect other devices.

3. Consider the amount of voltage drop when selecting cable sizes. Increase the cable size when the

voltage drop exceeds 2% of the motor rated voltage. The amount of voltage drop can be calculated

using the following formula:

Line drop voltage (V) = 3 × cable resistance (Ω/km) × cable length (m) × current (A) × 10

-3

Table 4.2.2 Cable Size and Tightening Torque (Three-phase 400 V)

Tightening

Torque

Nm ( lb.in.)

Applicable

Cable Size

mm2

Suggested

Cable Size

AWG,

kcmil

Applicable

Cable Size

AWG,

kcmil

Applicable

Cable Size

mm2

DC-,DC+1,DC+2,B1,B2,

GND,R/L1,S/L2,T/L3,U/

T1,V/T2,W/T3,PE

DC-,DC+1,DC+2,B1,B2,

GND,R/L1,S/L2,T/L3,U/

T1,V/T2,W/T3,PE

DC-,DC+1,DC+2,B1,B2,

GND,R/L1,S/L2,T/L3,U/

T1,V/T2,W/T3,PE

DC-,DC+1,DC+2,B1,B2,

GND,R/L1,S/L2,T/L3,U/

T1,V/T2,W/T3,PE

R/L1,S/L2,T/L3,P,DC+,D

C-,U/T1,V/T2,W/T3

R/L1,S/L2,T/L3,P,DC+,D

C-,U/T1,V/T2,W/T3

Loading...

Loading...