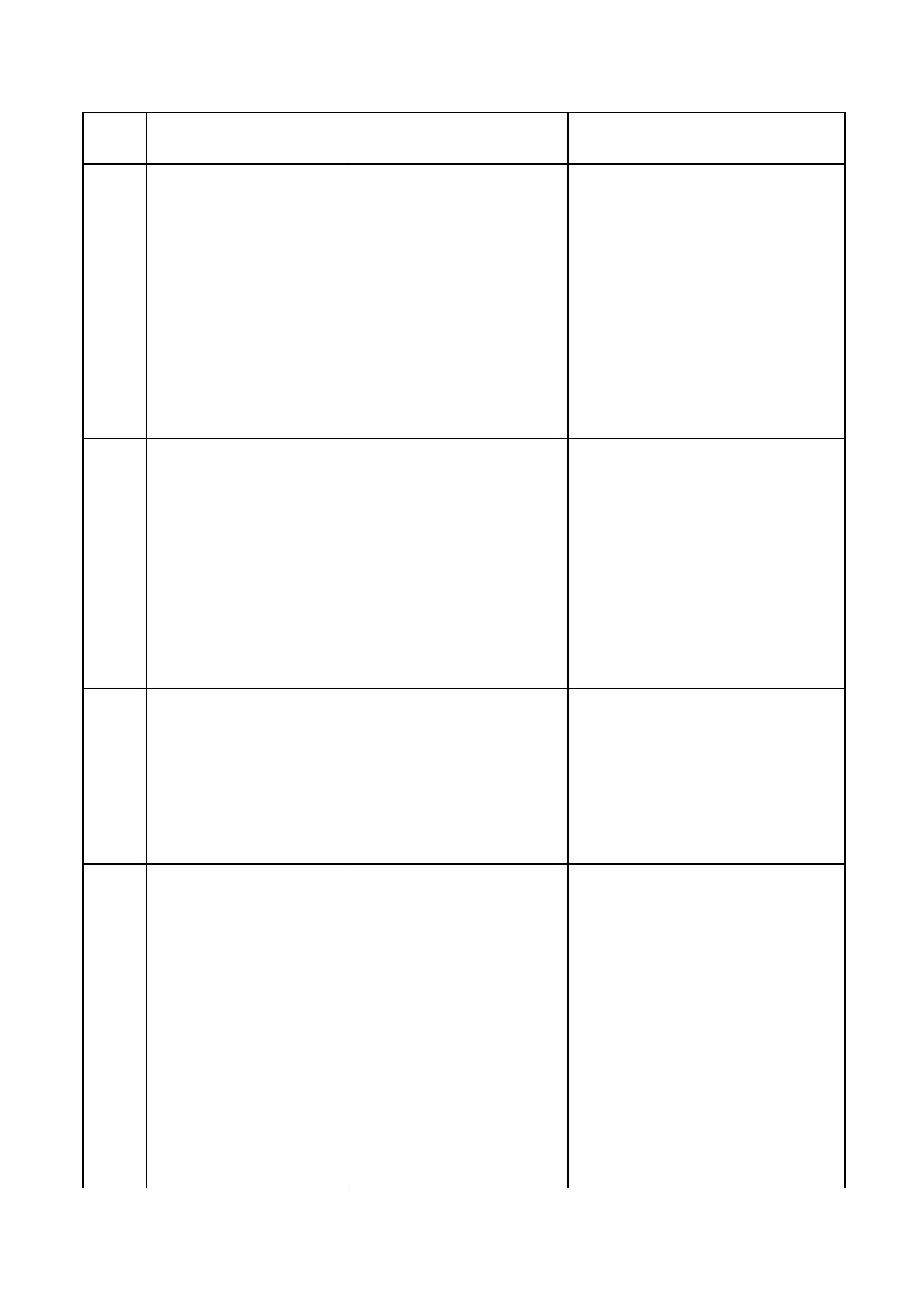

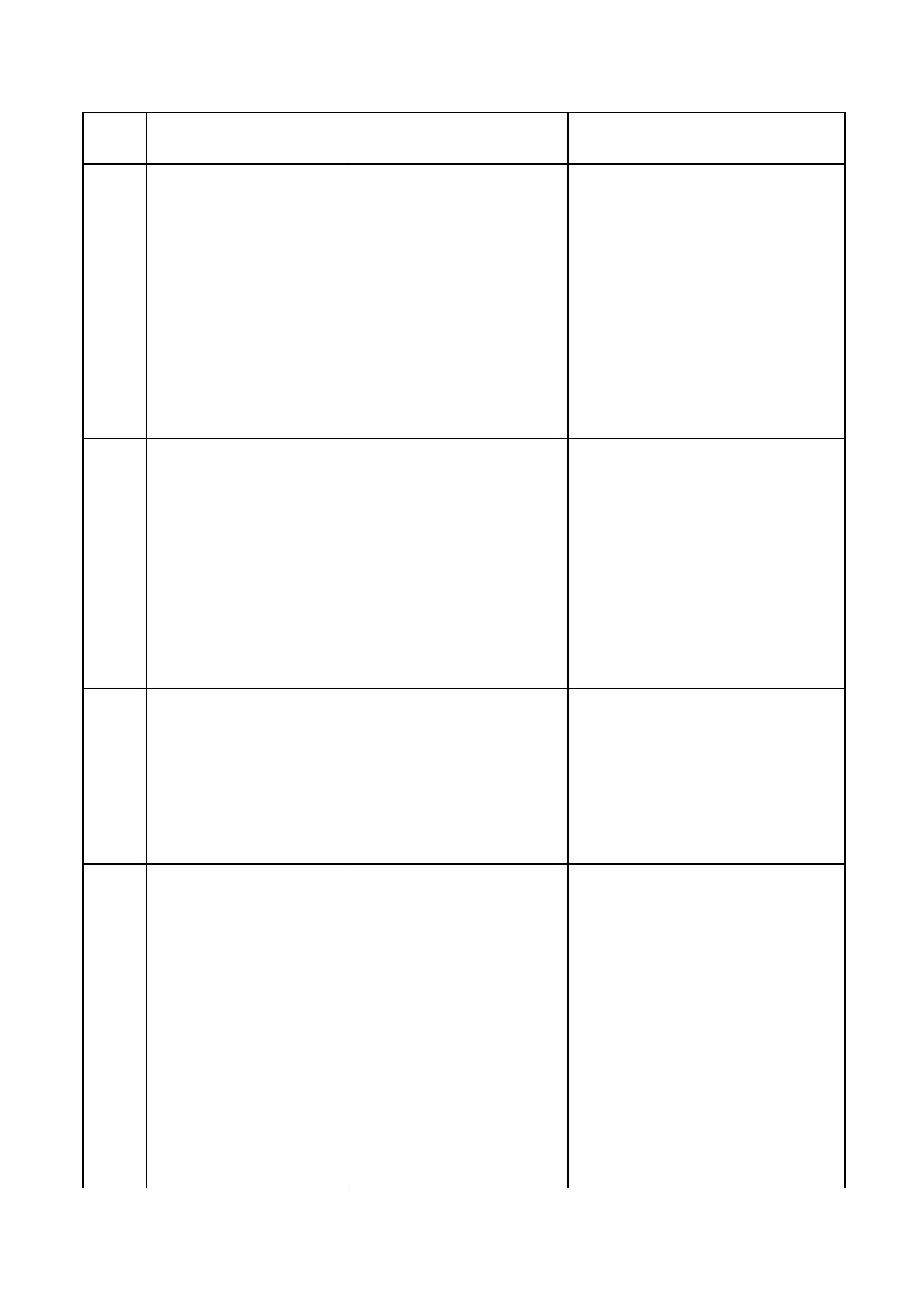

156

Heatsink temperature

over 95°C

2. Internal cooling fan

stopped operating

3. Bad air flow due to

insufficient room.

a. Improve the air flow inside the

enclosure panel

b. Install an air conditioner or fan

to cool the environment

c. Remove any possible source of

heat

2. Measure the output current

a. Reduce the load

b. Lower setting in C6-00

( Carrier Frequency Option )

3.Replace the cooling fan

Motor Overheat

The temperature signal

from motor temperature

sensor via the

multi-funtion analog

input (E3-01=20)

exceeded the overheat

detection level of the

drive.

1. Fault on the machinery

(e.g., machinery is locked

up)

2. Motor overheat

1. Check the machinery status

2. Check the load, acceleration /

deceleration time and cycle time

a. Reduce the load.

b. Increase the C1-00 to C1-07

(Acc./Dec. Time) settings

c. Adjust d1-02 to d1-11 (V/F

Characteristics)

Overtorque Detection 1

The current has

exceeded the torque

level set to P6-01 for

longer than the time set

to P6-02

1. Incorrect parameter

settings

2. Malfunction on

machinery

1. Reset P6-01 and P6-02

2. Check machinery and load

status

Overvoltage

Voltage in the DC bus

exceeded the

overvoltage detection

level

1.200 V class: 410 V

2.400 V class: 820 V( 740

V when d1-01<400 )

1. Drive input power has

surge voltage entering

2. Machinery output short

circuit

3. Ground fault in the

output circuit causes the

DC bus capacitor to

overcharge

4. Electrical signal

interference causes drive

malfunction

1. Install a DC link choke

Voltage surge can result from a

thyristor convertor and phase

advancing capacitor using the

same input power supply

2. Check the motor power cable,

relay terminals and motor

terminal box

3. Correct grounding shorts and

reapply power

4. Check the solutions for

interference suppression

»Check the control circuit lines,

Loading...

Loading...