24

and W respectively. Ensure the motor and drive terminals are in same phase sequence or

the motor will rotate reversely.

Do not connect power cable to output terminals of the drive. Failure to comply could

cause drive damage and a fire.

4.2.2.3 Braking Unit Terminal:

If the drive is used in a high-frequency or heavy duty application which requires frequent

braking or shorter deceleration time, install an optional braking unit to increase the

braking torque.

Please refer to the wiring diagram when installing braking unit.

4.2.2.4 Ground Terminal

Use grounding cables of dimensions regulated by electrical equipment standard. Shrink

wiring distance to prevent leakage current resulting unstable electrical potential at the

terminal distant from grounding terminal.

Do not use share the same grounding cable with welding machines or any device

requiring large current. Failure to comply could cause drive or equipment malfunction.

Do not wind the grounding cable when multiple drives are installed. Failure to comply

could cause drive or equipment malfunction.

Ensure the neutral of the input side and drive terminal " “ are grounded

according to the local electrician regulations. 3WYE (e.g. TN and TT) system are

suggested for the drive primary side.

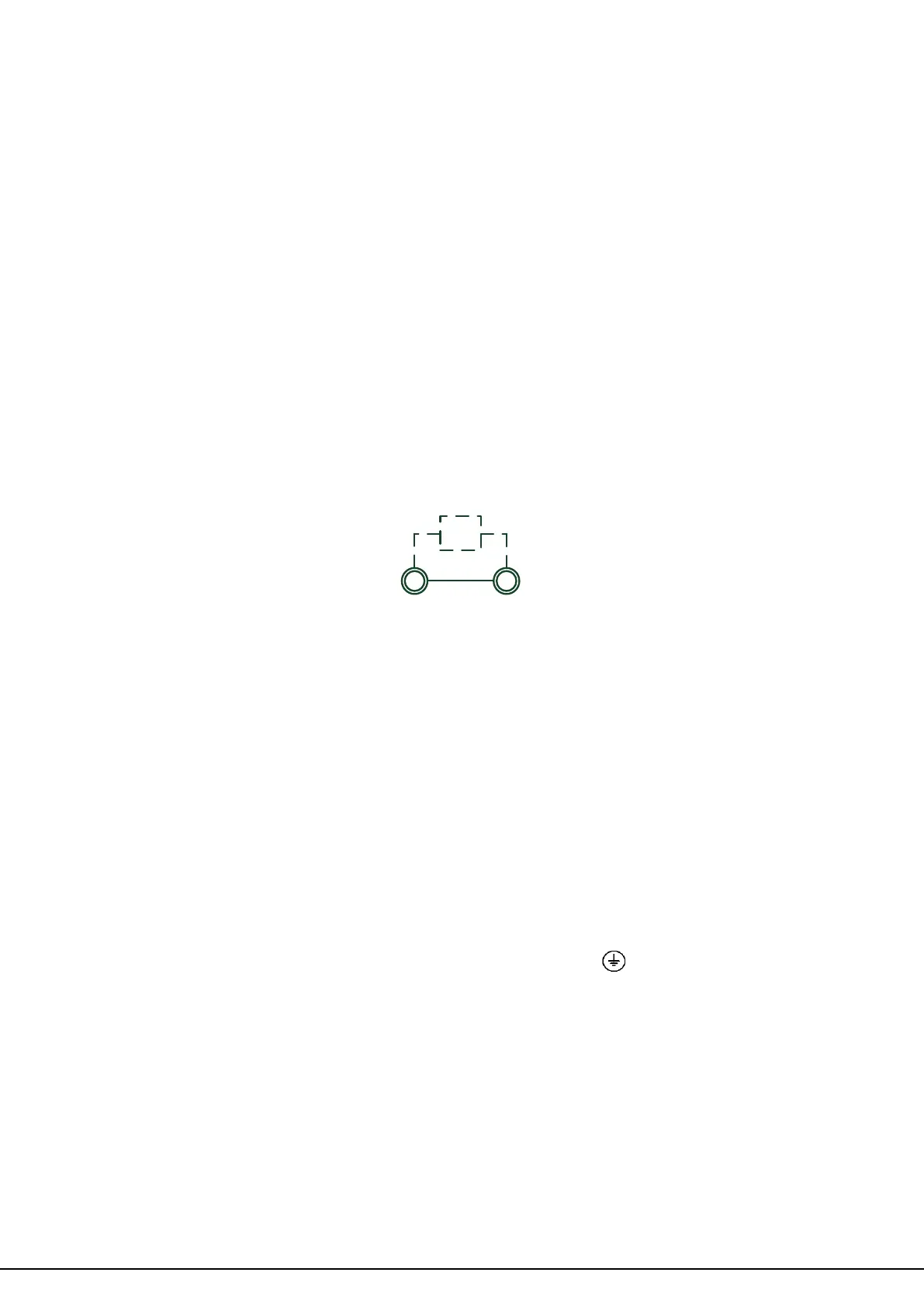

4.2.2.5 Jumper

EVO6000 complies with the European LVD standard EN 61800-5-1 (2007) reducing the

current leakage to below 10mA DC under testing condition regulated by IEC 60990

(1999).

Loading...

Loading...