57

Feeds back flow data to keep a constant flow level

Feeds back temperature data to maintain a constant

temperature by control the fan speed.

Thermistor, thermocoupler

■ PID Target Input Methods

The PID target can be input according to the methods showed in Table 6.6. If more than one

PID targets are input, it will be selected as per the priority.

Ex. When E3-01=9 (PID Target) and E5-00=2 (PID Target), the signal from terminal A1 will be

selected as the PID target.

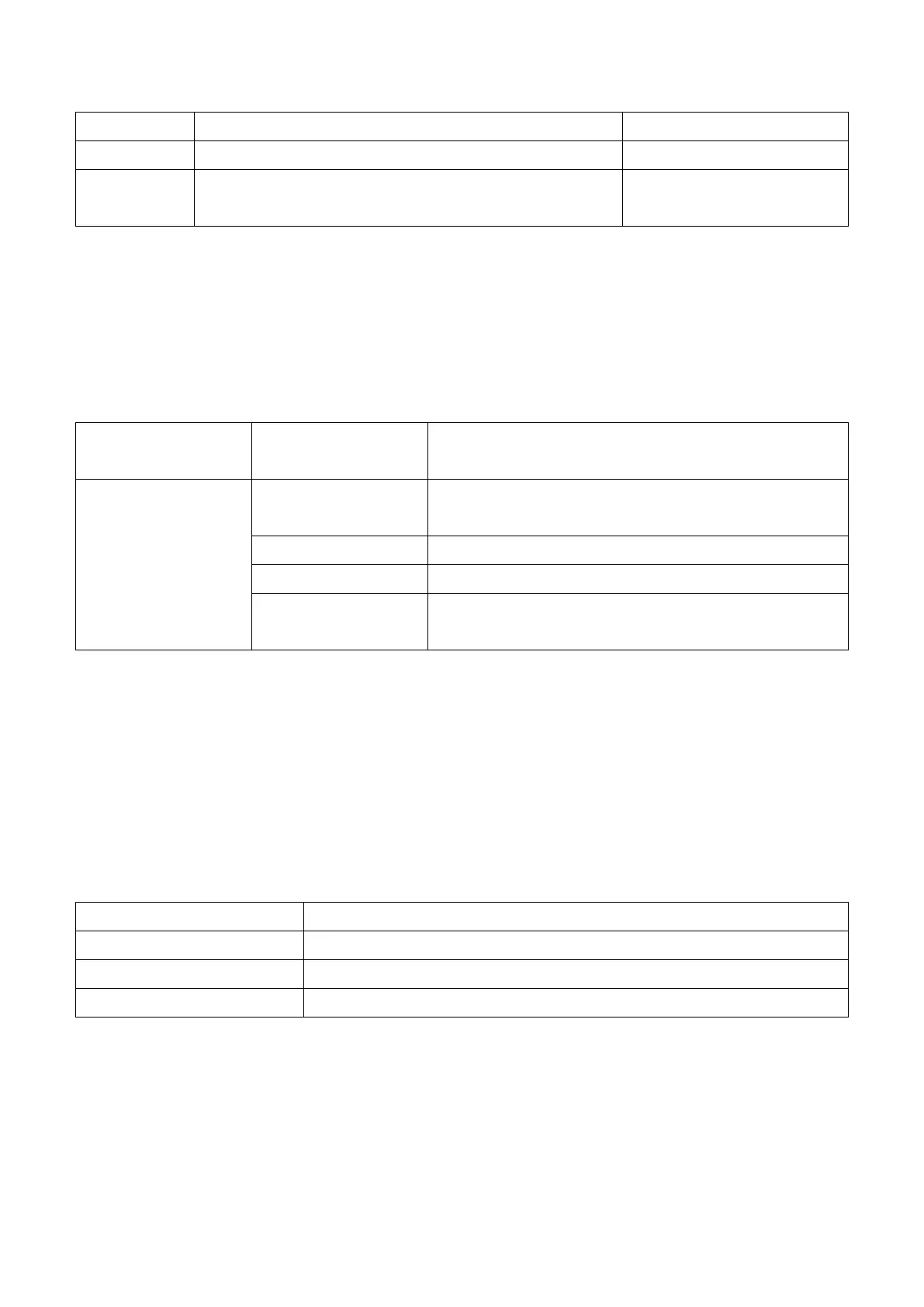

Table 6.6 PID Target Input Sources

Set E3-01 to 9 (PID target)

Set E3-07 to 9 (PID target)

Set E5-00 to 2 (PID target)

Set b5-17 to 1, and input the PID target to b5-18.

Set bit 1 in Modbus register 000FH to 1 (PID target

input) and input the target to 0006H.

Note: When both terminal A1 and A2 are set to 9 (PID Target), oPE07 fault will be triggered.

■ PID Feedback Input Methods

There are two input methods. The first is to input one feedback signal for normal PID control.

The second is to input two signals to control the deviation in between.

Normal PID Feedback:

Selects the PID feedback signal in the source listed in Table 6.7.

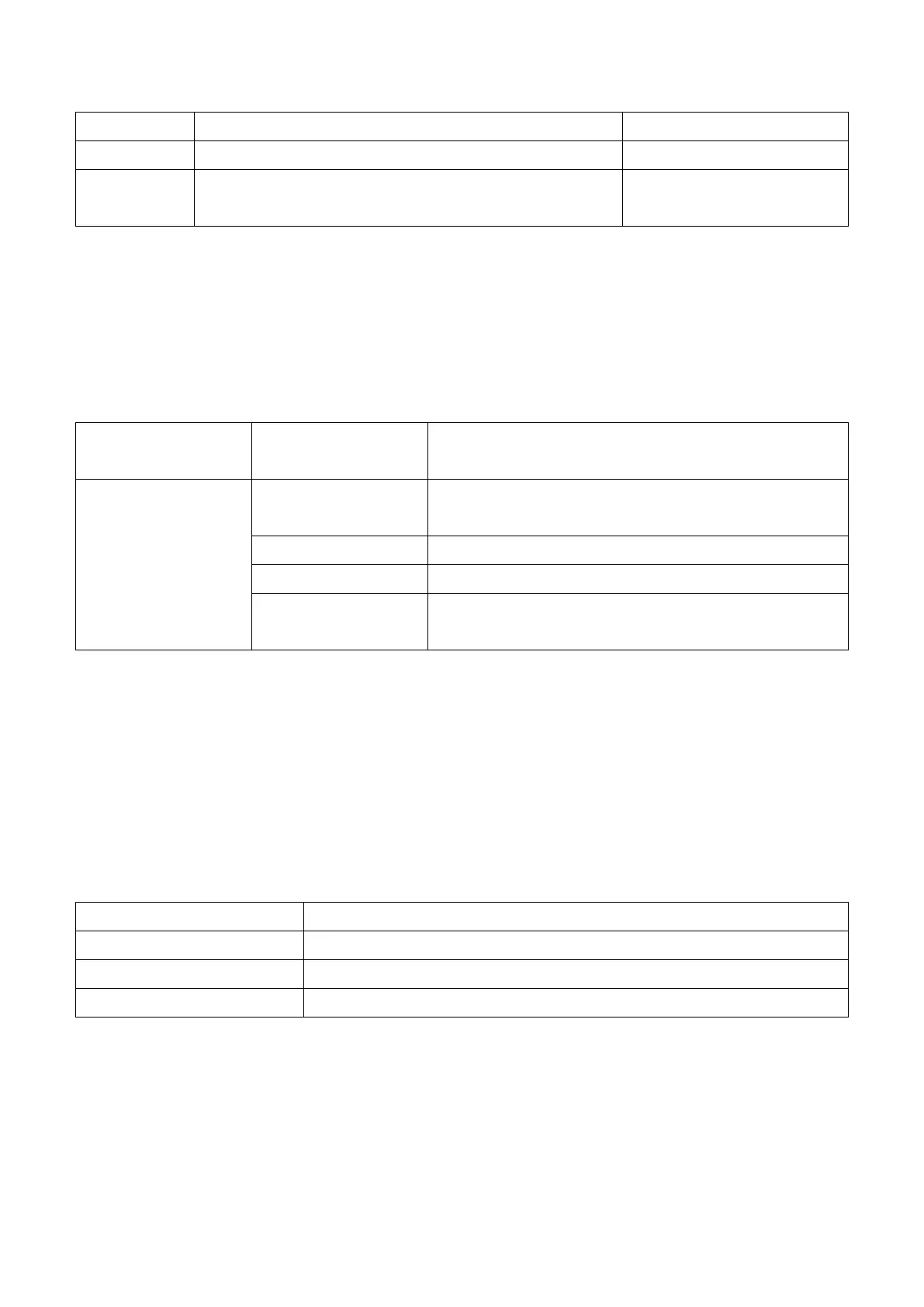

Table 6.7 PID Feedback Sources

Set E3-01 to 8 (PID feedback)

Set E3-07 to 8 (PID feedback)

Set E5-00 to 1 (PID feedback)

Note: When more than one PID feedback input source is assigned, oPE09 fault will be triggered.

■ PID Differential Feedback

Selects the second PID feedback signal used for deviation calculation in Table 6.8. Assigning a

differential feedback input will automatically activate the differential feedback function.

Table 6.8 PID Differential Feedback Sources

Loading...

Loading...