44

COMPILER TECO/ATL

REG. CODE

1-5302-296

MODEL N°

50510

DATE OF ISSUE

01.89

REVISION 02

ENDORSED

DATE

17.04.2003

105

103

104

VIII

Starting with electronic speed governor

(see lay-out on page 43)

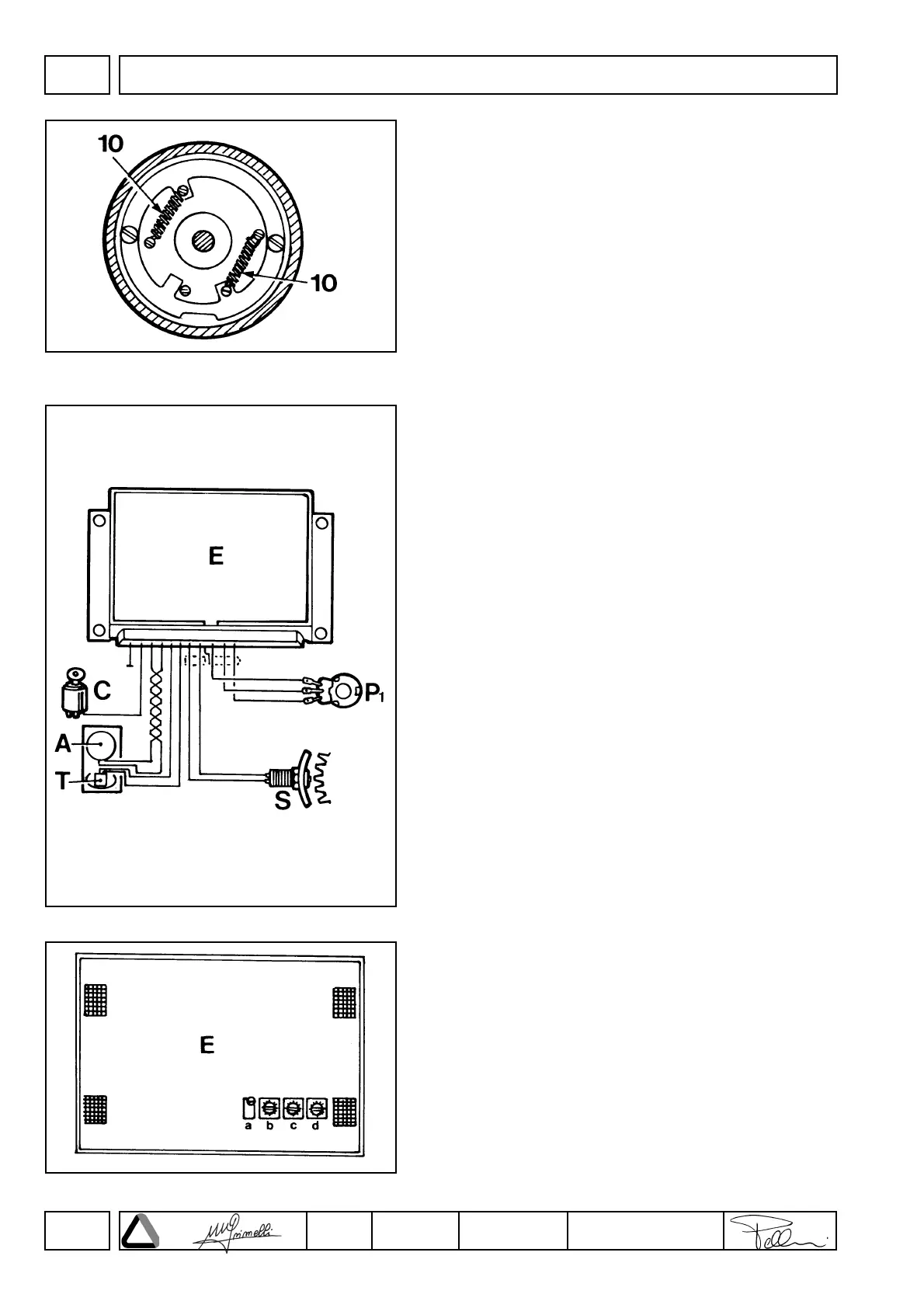

In position 0 the engine is not working and no part is energized. The

rack rod is in stop position (retained by two springs 10 inside

actuator A).

By rotating key C to position 2 the electromagnet withdraws allowing

the rack rod to reach ìts highest delivery being connected to the

actuator at its max. ievel of energization. When the engine,

immediately after starting, reaches 1000 r.p.m, the controller

reduces the actuator position, after 1 second switches off the

electromagnet T and after more 0.5 seconds returns at his normal

position with the engine speed set as per position of potentiometer

P1.

Engine running with electronic speed governor

The engine starts running at the pre-set speed.

Potentiometer P is located either inside the control box E or on

control panel P1.

In case of an external potentiometer P1 the engine speed can be set

at any point between the idling and full speed in on-load conditions

(setting performed on the control box in the test room).

The electronic control box E controls actuator A (by sending or cutting

off the power supply) to keep the speed set through P1 constant

independently of the absorbed load.

Control box E prevents the engine from starting (or stops it) in case

of no power supply or in case connection with r.p.m. sensor S is

broken (or short-circuited).

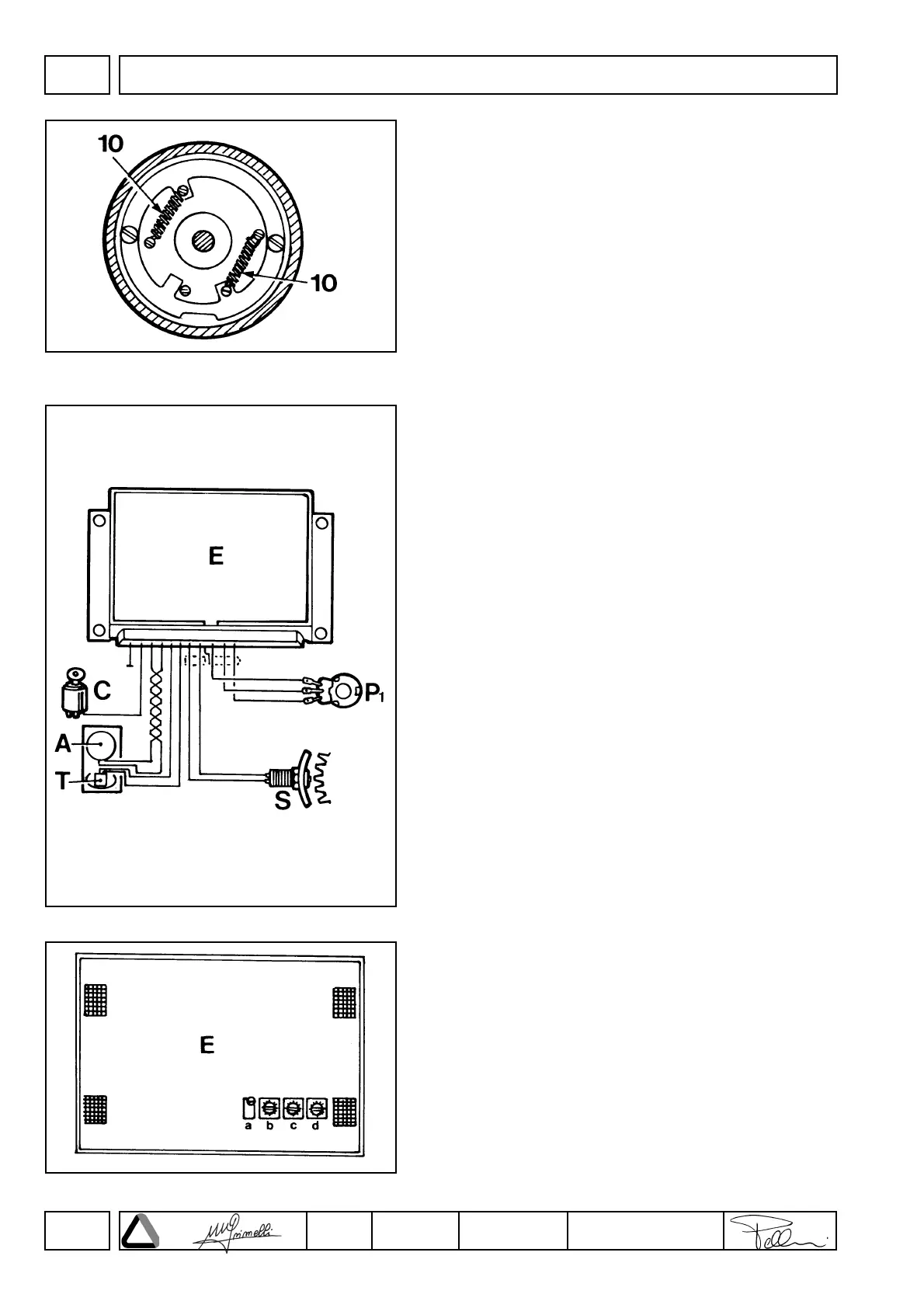

Electronic speed governor control box

Control box E features four setscrews which must be positioned on

the test bed (torque dynamometer) along wilh the engine.

a) Setscrew for speed control (r.p.m.)

b) Setscrew for sensitivity adiustment when the engine is

running at full speed.

c) Setscrew tor sensitivity adjustment at low speed.

d) Setscrew for extra fuel release; once correctly positioned, this

setscrew is generally sealed.

DISASSEMBLY/REASSEMBLY

Loading...

Loading...