54

COMPILER TECO/ATL

REG. CODE

1-5302-296

MODEL N°

50510

DATE OF ISSUE

01.89

REVISION 02

ENDORSED

DATE

17.04.2003

140 141

138

139

X

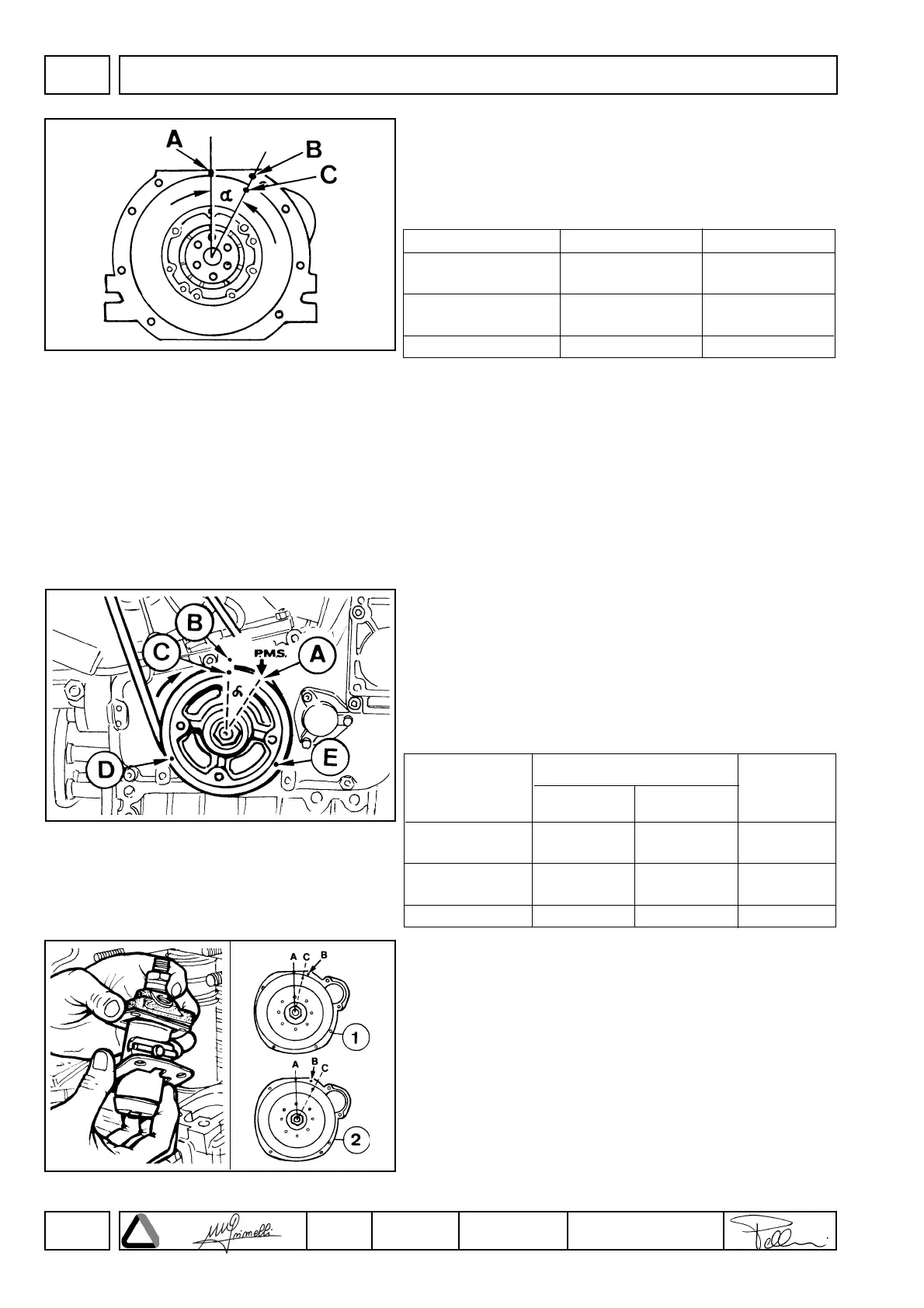

Injection timing reference marks on crankcase and flywheel

A = Piston reference mark al the top dead centre

B = Injection timing reference mark compared to A

(A - B) = Distance in mm.

C = Piston reference mark in injection tíming position.

αα

αα

α = Reference angle in degrees

Values given in mm.. have been detected al the periphery of a

standard flywheel with 288 mm diameter.

For engines set at 3000 r.p.m.

For engines set at 1500÷2000 r.p.m.

For engines set at 3000 r.p.m.

Note: The clear difference in static injection timing between engines

type 11 LD535-3, 11 LD625-3 and 11 LD626-3 is lo be found in the

special plunger machining found in the latter. See page 50.

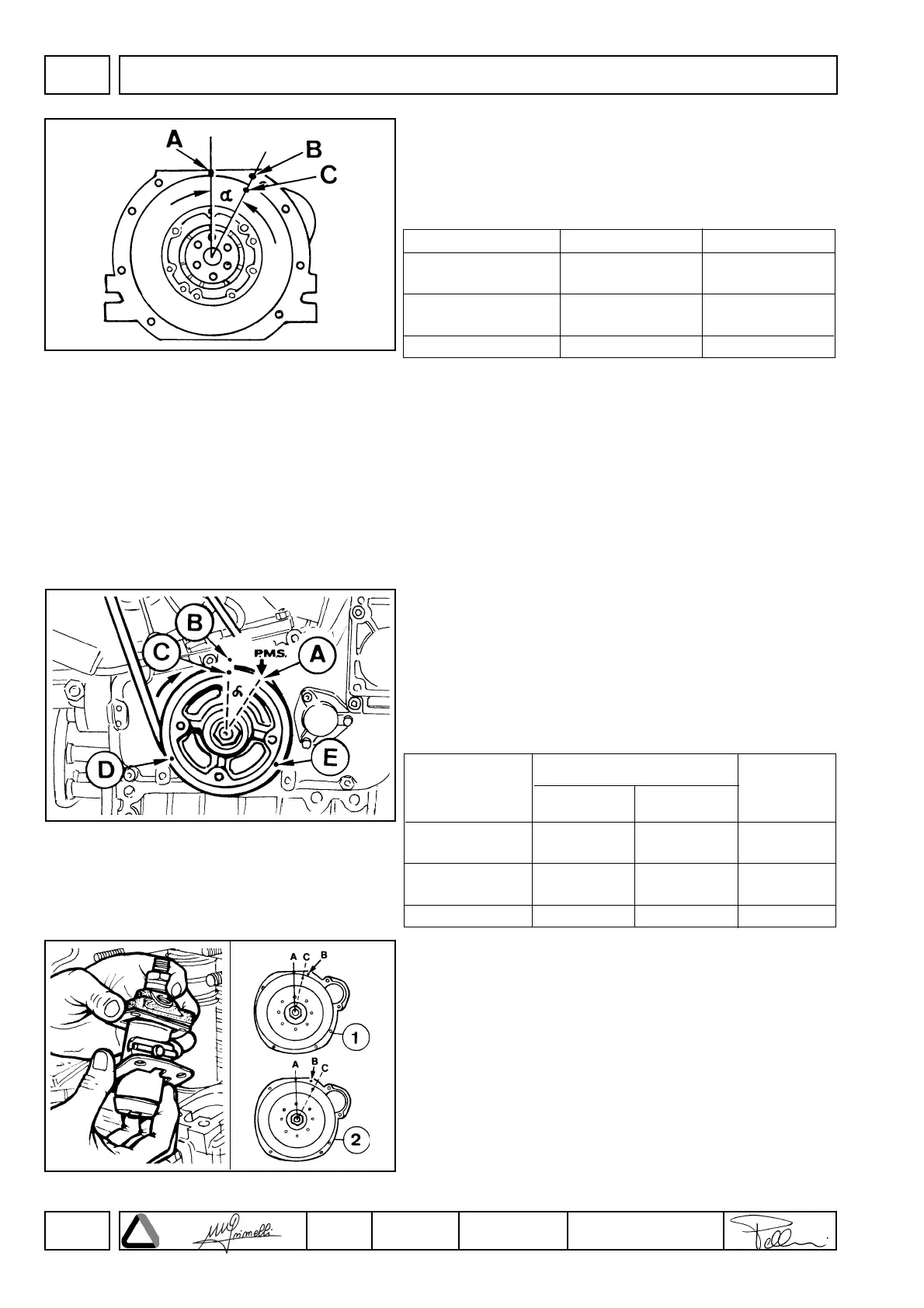

Injection timing reference marks on the pulley and the gear cover

A = Gear cover reference arrow al top dead center P.M.S. (T.D.C.),

obtained with a casting process.

B = Injection timing mark with reference to A

(A - B) Distance in mm.

C, D, E Injection timing mark or top dead center for the

individual pistons

a = Reference angle in degrees

Injection timing correction

If reference mark C does not match with B follow examples 1 and 2.

1 Example of late injection timing: remove shims under the pump lo

make C match with B.

2 Example of early injection timing: add shìms under the pump to

make C match with B.

Note: By adding or removing a 0.1 mm shìm under the pump C is

delayed or advanced by approximately 3 mm.

FUEL SYSTEM

(A÷B) mm *

60÷65

55÷60

37÷42

α

24°÷26°

22°÷24°

15°÷17°

Engine type

11LD535-3

11LD625-3

11LD535-3

11LD625-3

11LD626-3

∗∗

∗∗∗

∗∗∗∗

Engine type

11LD535-3

11LD625-3

11LD535-3

11LD625-3

11LD626-3

Pulley dia.

142 mm

29,7÷32,2

-

18,6÷21

Pulley dia.

163 mm

-

31÷34

-

(A÷B) mm

α

24°÷26°

22°÷24°

15°÷17°

Loading...

Loading...