SECTION 3. MAINTENANCE

3-7 Valve Clearance

Valve clearance inspection and

adjustment must be performed with the engine

cold.

1) Remove the cylinder head cover, and pull the

starter grip (until a resistance is clearly felt) to

set the piston at top dead center of the

compression stroke (both valves fully closed).

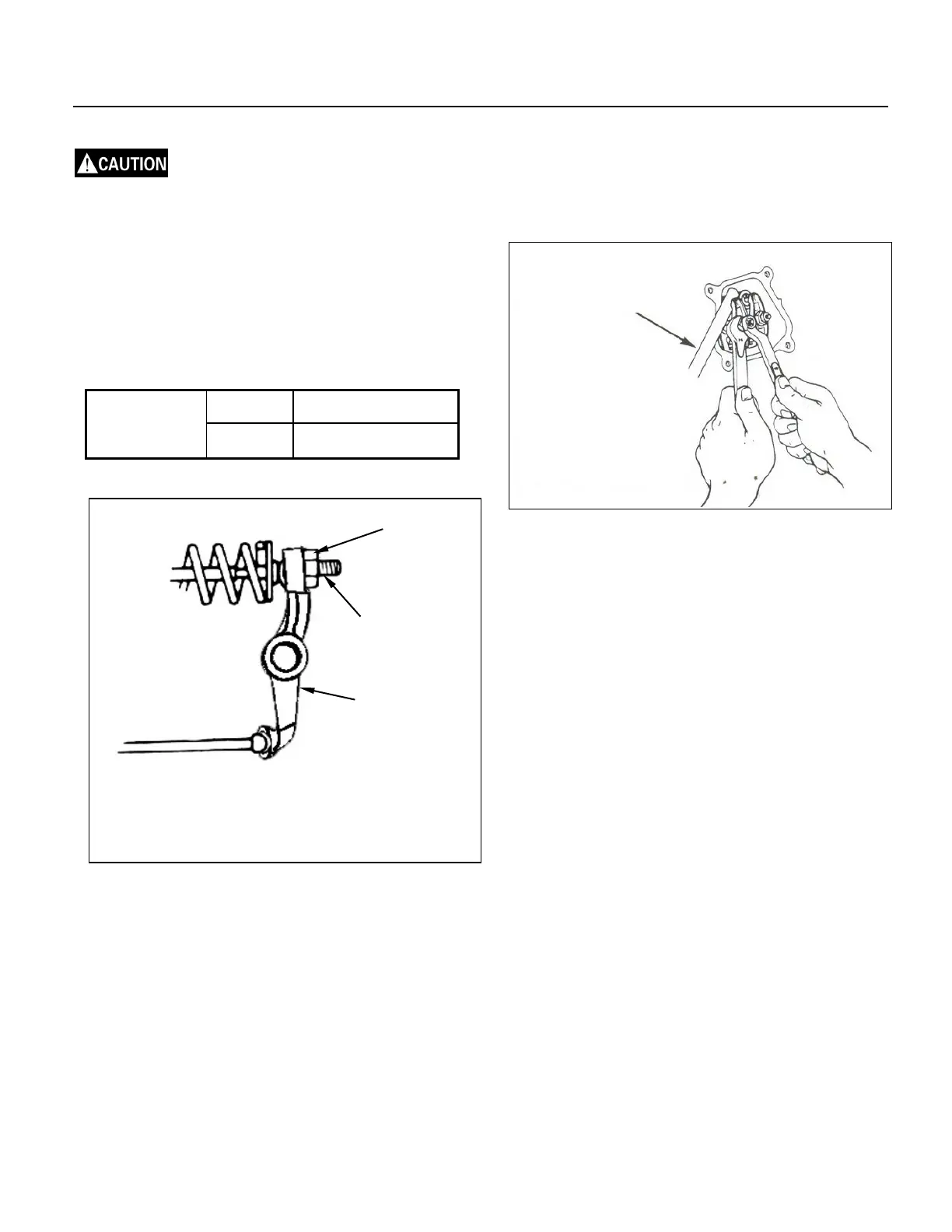

2) Insert a feeler gauge between the rocker arm

and valve to measure valve clearance.

3) If adjustment is necessary, proceed as follows:

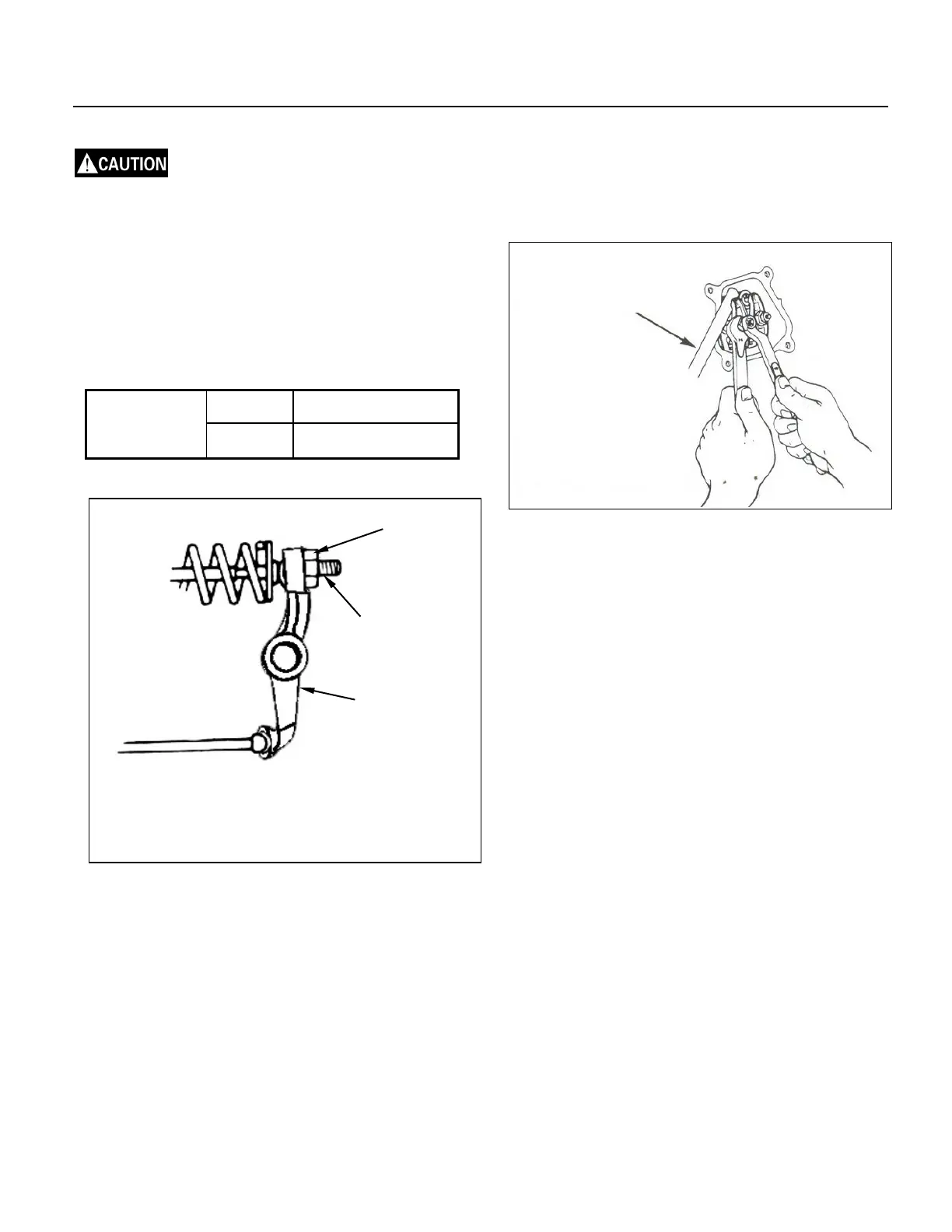

a) Use a clamp to hold the rocker arm pivot

and use a wrench to loosen the pivot lock

nut.

b) Turn the rocker arm pivot to obtain the

specified valve clearance.

c) Retighten the lock nut while using a clamp

to hold the rocker arm pivot.

d) Recheck valve clearance after tightening

the lock nut.

Standard

valve

IN. 0.05±0.02 mm

EX. 0.05±0.02 mm

To increase valve clearance, screw out the pivot

To decrease valve clearance, screw in the pivot

- 10 -

Loading...

Loading...