8.3.2 Installation and Handling

To lower the pumps into the borehole, a crane or hoist is

recommended, depending on the size and weight of your

pump system.

All parts have to be strong enough to withstand the weight

of the pump, the motor, the motor cable and the pipe

system.

It is also helpful to lower a pump dummy into the borehole

before you lower the pump to make sure that the hole

is completely free and the pump can slide into the hole

without obstructions.

WARNING – Never stand under

suspended loads.

WARNING – Always take suitable secu-

rity precautions (e.g. a strong safety rope)

to safeguard the pump against slipping

into the well during installation!

CAUTION – Be careful not to bend the

pump, take particular care with centrifu-

gal (C) pumps with a high number of stag-

es. Make sure that the pump never stands

on the motor cable, that the cable does

not get jammed or damaged by sharp

ledges or that the cable is not pulled or

jerked where it enters the motor.

CAUTION – Helical rotor pumps (“HR

pumps”) have an eccentric rotor that

causes vibration when the pump is run-

ning. This vibration is normal an will not

damage the pump. the plumbing equip-

ment such as pipe connectors, riser pipes,

etc. must be able to withstand vibrations

and should be made of decent quality.

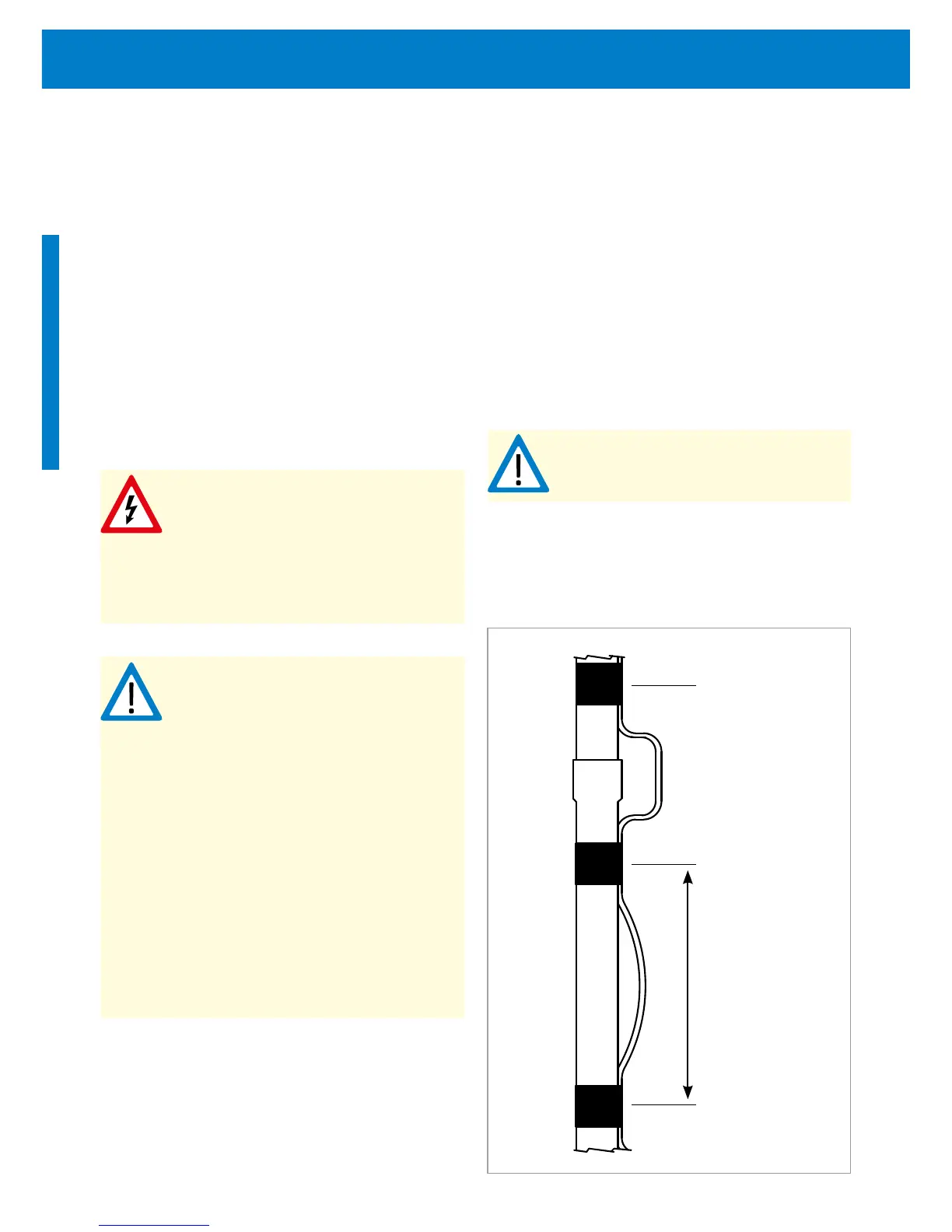

During the process of lowering the pump into the well the

motor cable has to be fixed properly to the pipe, see “Figure

10: Fixing of the motor cable at a joint and a strait pipe” on

page 36. Where a plastic pipe is used, the longitudinal

stretch of the pipe under load has to be considered by

leaving a sufficient gap between the pipe and the cable! The

cable should be fixed with water-resistant tape. It is a good

installation practice to form a loop with the motor cable

near the pump and repeat it about every 40 m / 130 ft along

the riser pipe. This will keep any tensile forces away from the

motor cable.

To extend the motor cable pay attention to chapter “8.1.2

Cable Splicing” on page 33. Round off the edges of a

flange to prevent damage to the cable. Do not fix the cable

tightly. Leave space for the pipes to expand. The cable needs

to get fixed every 3 m.

NOTE – Measuring and noting down the

distances between the fixing will help to

lower the pump to the right depth.

5050

77

77

50

Figure 10: Fixing of the motor cable at a joint and a strait

pipe

tape

3 m

36 Pump Installation

Loading...

Loading...