8.5.2 Pipe Sizing

LORENTZ pump systems are extremely efficient. It is impor-

tant to keep this efficiency throughout the entire system.

A main reason for loss of efficiency is pipe pressure losses.

Make sure that you have allowed for pipe pressure losses

during the sizing process of your system.

CAUTION – Consult COMPASS or a pipe

pressure sizing chart to determine the

correct pipe size. Oversize the pipe line to

reduce the pressure drop.

CAUTION – The length of the inlet and

of the outlet pipeline must be taken into

consideration when calculating pressure

losses.

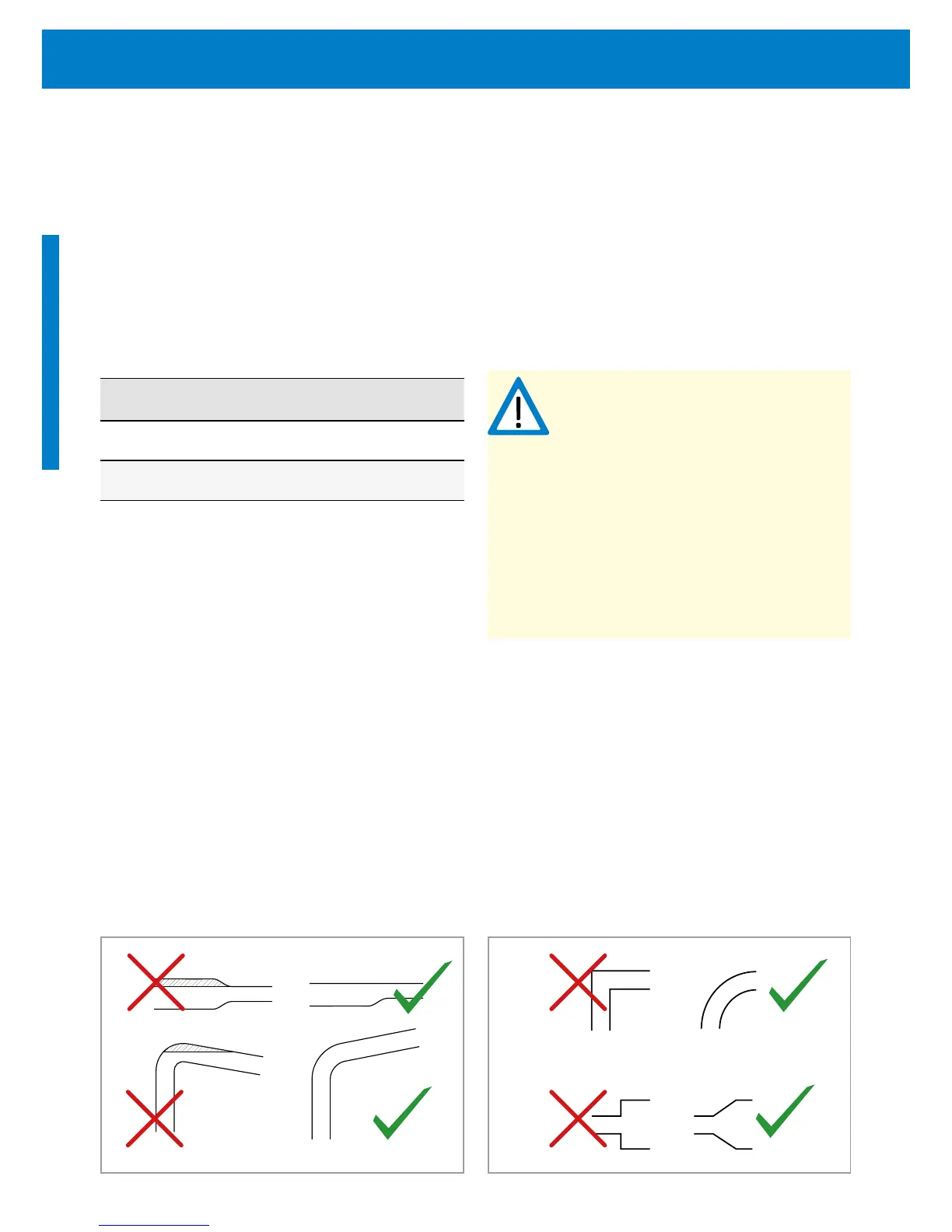

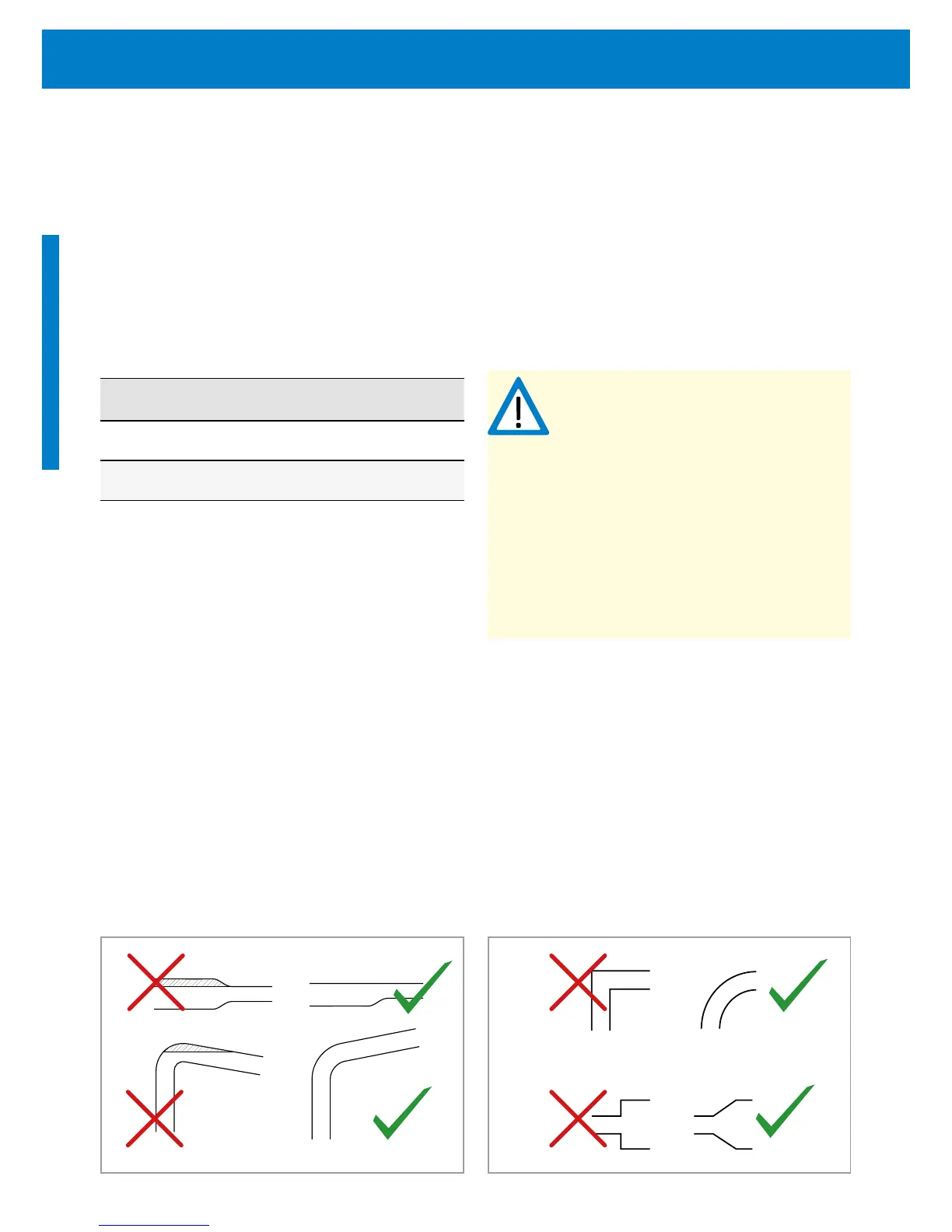

CAUTION – Air locks must be avoided at

the inlet pipeline. Avoid sharp 90° elbows

and sharp pipe size adaptors.

Figure 17: Prevent air locks in pipes Figure 18: Avoid 90° elbows and size adaptors

Operating noise – Make sure, by applying appropriate

measures, that the local environment will not be impaired by

pump operating noise.

Table 8: Operating noise

Pump system Max. noise level

PS2-600 CS-17-1 65db

PS2-1800 CS-37-1 68db

Space – During installation, make sure that there is enough

space available to permit subsequent disassembly of the

motor unit in the direction of the motor fan (minimum 120

mm / 4.7”) and of the strainer basket above (minimum 140

mm / 5.5”).

When installing in very small spaces the natural cooling may

be insufficient and additional ventilation may be required.

Carefully consider the ventilation in order not to exceed the

maximum ambient temperature.

46 Pump Installation

Loading...

Loading...