LOUP ELECTRONICS

•

1-877-489-5687

•

WWW.LOUPELECTRONICS.COM

7

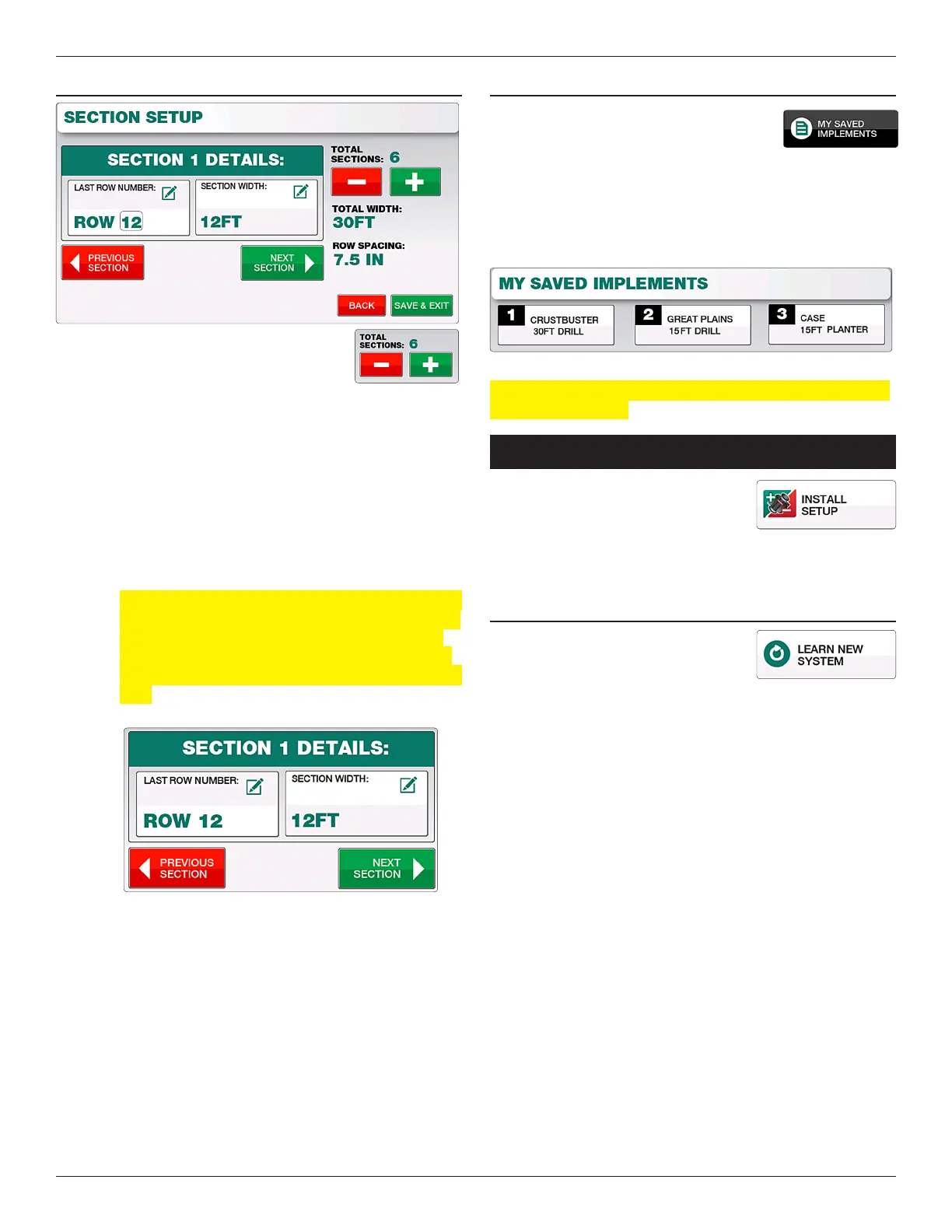

WIDTH & sEcTION sETuP

1. Select the number of sections

(up to 12 possible)

2. Starting with Section 1, enter the last

population sensor number installed on that section followed by

the width for that section.

Example: If installing 6 population sensors on a 30, 3-section

folding drill, the last row number for section 1

would be “Row 2”, section 2 would be “Row 4” and

section 3 as “Row 6”. Each Section Width would be

10.

Note: e Row Number here is referring the number

assigned by the Loup Elite monitor when sensor was

learned. Row numbers can be learned in dierent

ways such as sequencial order (1-6) or to match the

physical row number on a drill (1, 16, 17, 32, 33, and

48).

3. Select the “Next Section” button to scroll to the next section.

Repeat steps 1 & 2. Each Section width will contribute to the

overall implement width.

When all sections are setup, check that the total width is

correct and Select “Exit & Save”.

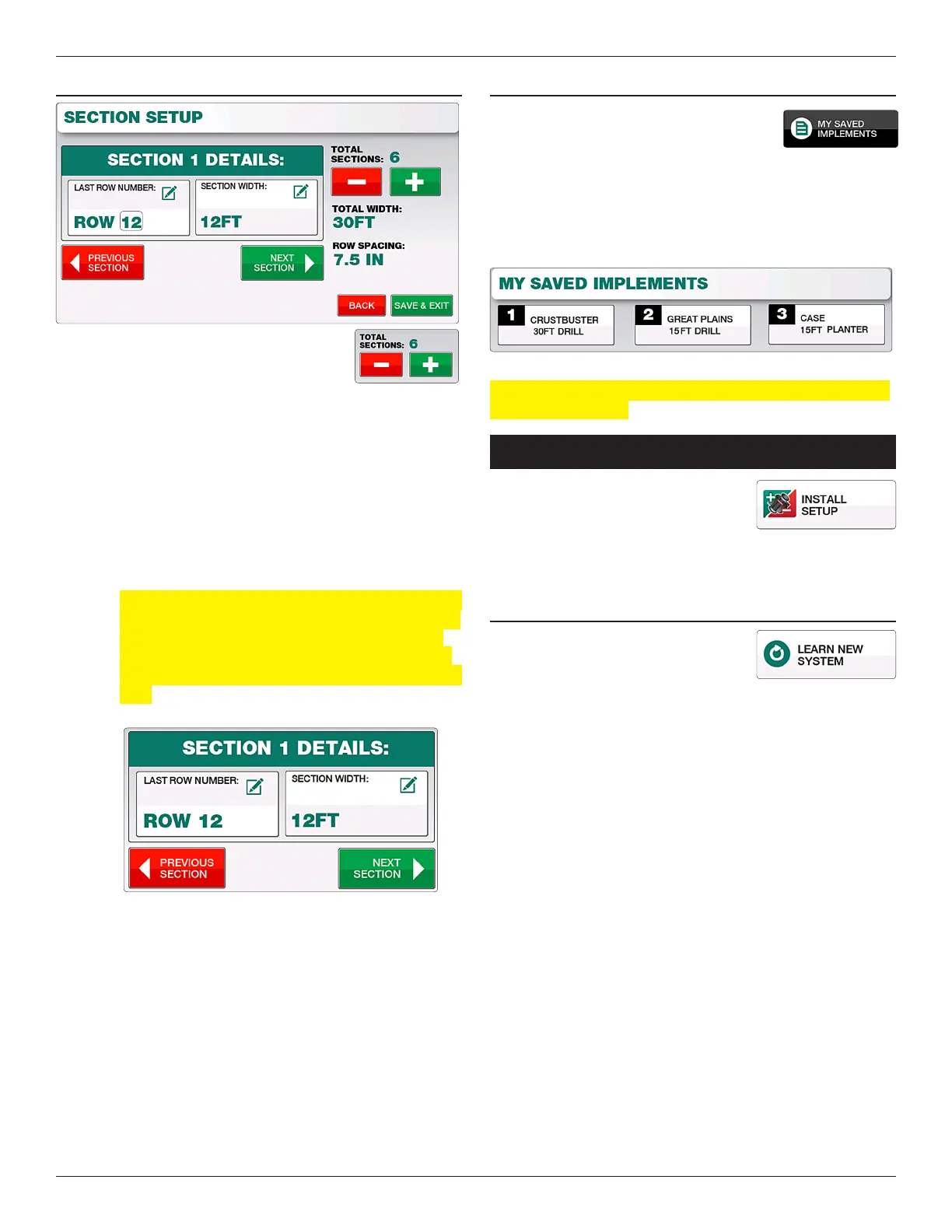

cHANgINg IMPLEMENTs

Up to three separate implements can be

selected on the Loup Elite. Unless pre-

congured by Loup, all three implements

will default as gravity drills. To switch implements simply select

the “My Saved Implements” button and select the implement

number you’d like. From here you can congure the type of

implement, make, width and so forth. All implement settings are

automatically saved as they are made.

Note: When selecting a dierent implement, the Elite console

needs to be restarted.

inSTall/SeTup Menu

Located by selecting “Menu” and “Install

Setup”. e Install/Setup Menu is used

to Learn a New system, Add new sensors

to your existing system or Remove specic sensors from your

implement.

LEARN NEW sysTEM

Select “Learn New System” if your

monitor did not come pre-programmed

or you wish to relearn all sensors.

1. Start by unplugging all sensors on the implement and then

selecting “Learn New System”. A popup will warn you that

all current sensors will be overwritten. Select “Yes, Learn

New System”.

2. e monitor will prompt you to Plug In Fbus sensors (all

us sensors have a 3 pin connector with white, black

and green wires) in the following order. e sensor being

prompted will automatically be learned upon connecting the

3 pin connector.

1. Speed Sensor: Sha mounted ground speed sensor

2. Li Switch

3. Rate Cal Sensor

4. Population/Row Sensors: Up to 32 sensors

5. Bin Level: Up to 6 bin level sensors

6. Sha Speed Sensor: Up to 6 possible Sha RPM

Sensors

7. Fan: Up to 3 Fan RPM sensors

8. Blockage Module: Up to 12 Modules with 192

runs of product detection.

Loading...

Loading...