12

12

The GS820 System

The GS820 System

2. For GS011 angle/length sensors only: Carefully

remove the cover of the GS101 cable reel.

3. Loosen the mounting screw in the slotted hole

of the angle sensor mounting plate.

4. Pivot the angle sensor slightly until angle

indication is correct. Repeat the angle validation

(step 1) as required.

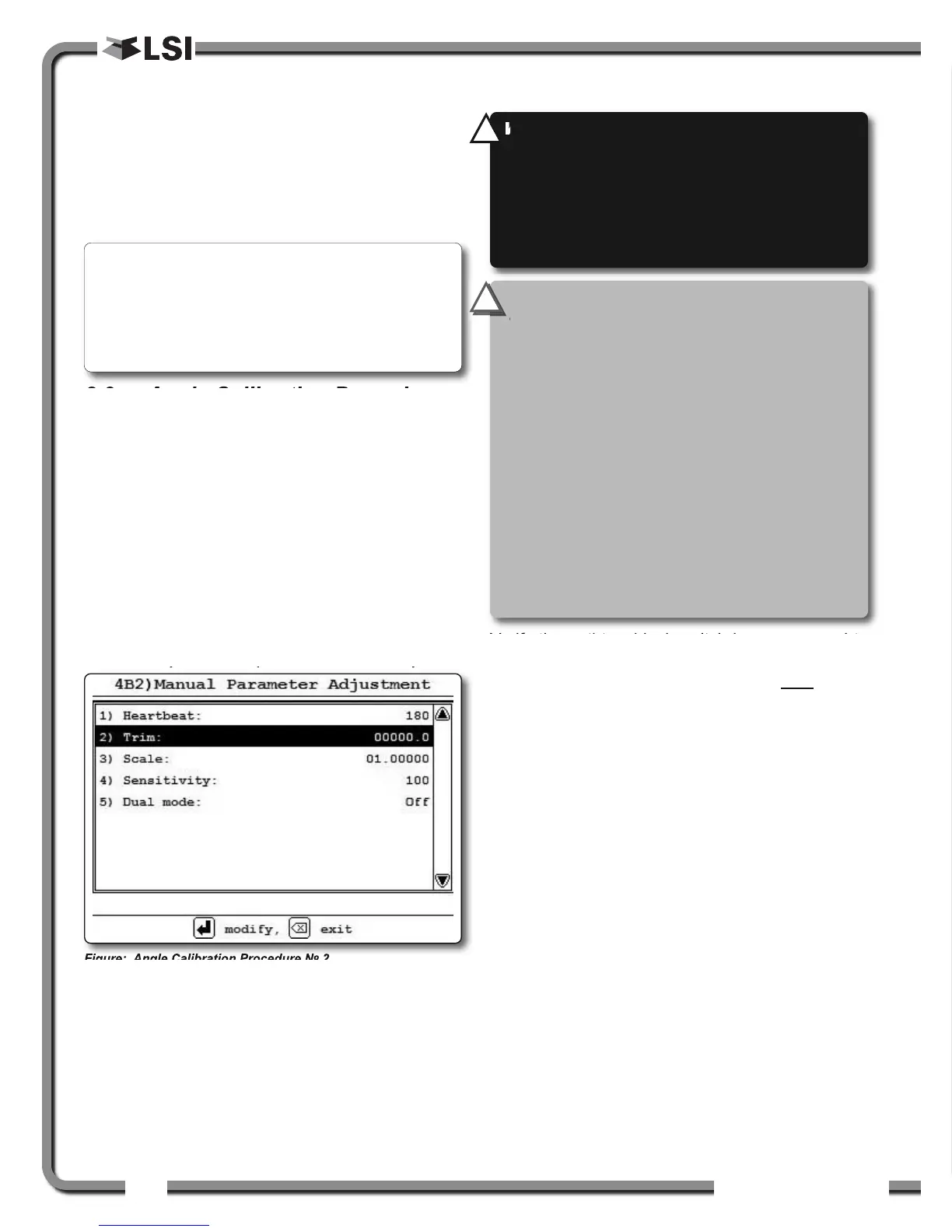

2.3c Angle Calibration Procedure

№ 2: Correct with the GS820

Calibrate angle indication by adjusting the trim (offset)

value in the GS820 display; the GS820 will then

communicate the updated trim value to the sensor.

1. Position the boom at a precisely known angle.

2. Go to menu 4) and select 4B) S

ENSOR CALIBRATION.

3. Enter the user password and press Enter.

4. Select 4B2) M

ANUAL PARAMETER ADJUSTMENT.

5. Use Up and Down to select the angle sensor

to be calibrated and press Enter.

6. Select 2) T

RIM: and press Enter to modify.

7. Use Up and Down to modify the trim value.

Example: If angle indicated is 0.3° over the actual

angle, adjust the trim value to -0.3.

Example: If angle indicated is 0.9° below the actual

angle, adjust the trim value to 0.9.

8. Press Enter to save changes.

9. Press Exit to return to the operation display.

10.Verify accurate angle indication at both very

high and very low angles.

2.4

2.4

Anti-Two-Block Switch

Anti-Two-Block Switch

Verify the anti-two-block switch is programmed to

the GS820 display. Switches shipped with displays

are pre-programmed in the factory. Test

: if the

switch has been programmed to the display then

the display will go in to two-block alarm when the

wire rope of the switch is released. Press Bypass

to silence the alarm until the next two-block event

or simulation. If the switch has not been

programmed to the display, this should be done

before proceeding with installation. See the section

How to Add a Sensor to the GS820.

2.4a GS050 Installation

1. Position the sensor mounting bracket. To

ensure that the sensor can pivot securely on the

mounting bracket throughout the full range of

boom angle, the mounting bracket must be

positioned at a 30° from horizontal with the

boom parallel to the ground and such that the

locking pin of the mounting bracket points up.

Bolt or weld securely.

Figure: Angle Calibration Procedure № 2

Note: When the angle sensor is moved very slowly,

it may take several seconds to see an update at the

GS820 display. Instead move the sensor up a couple

of degrees, and then bring it back down to where it

should be. The small light on the angle sensor

flashes when it transmits a new value to the display.

WARNING!

Keep the anti-two-block switch

away from the boom and any connecting

metal structures when welding mounting

brackets to the boom. Proximity to welding

may cause permanent damage to the anti-

two-block switch and render the anti-two-

block system unsafe.

!

!

IMPORTANT!

To ensure reliable radio

communication between the anti-two-block

switch and the GS820 display the following

conditions must be respected:

• The antenna of the anti-two-block switch

should not be in contact with metal.

• The anti-two-block switch antenna should

point to the left or to the right of the boom;

it should not point directly to, or away from,

the GS820 display.

• The anti-two-block switch antenna should

have a clear line of sight to the GS820

display; in most cases this means mounting

the sensor on the same side of the boom as

the operator's cab.

!

!

Loading...

Loading...