6

6

The GS820 System

The GS820 System

2.1

2.1

Display GS820

Display GS820

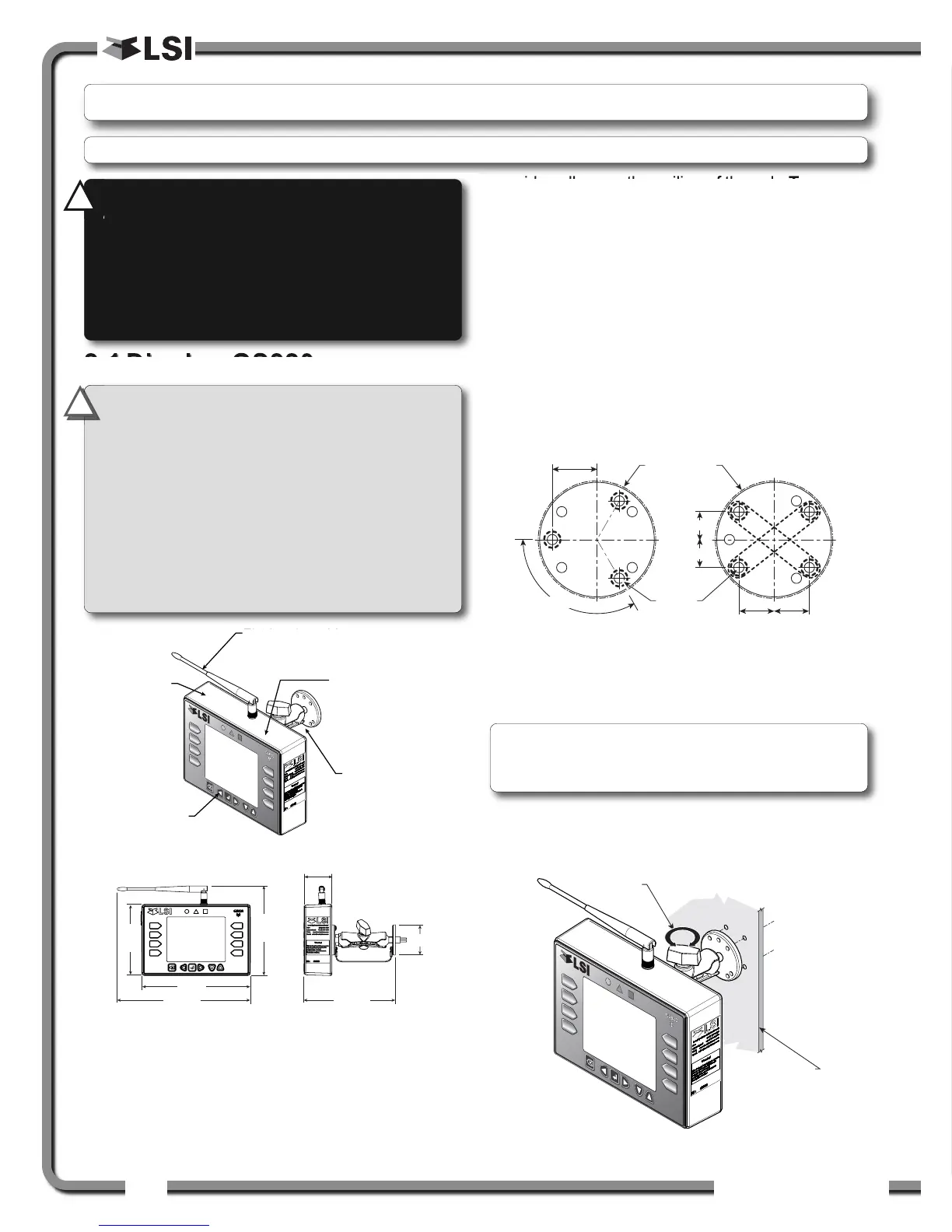

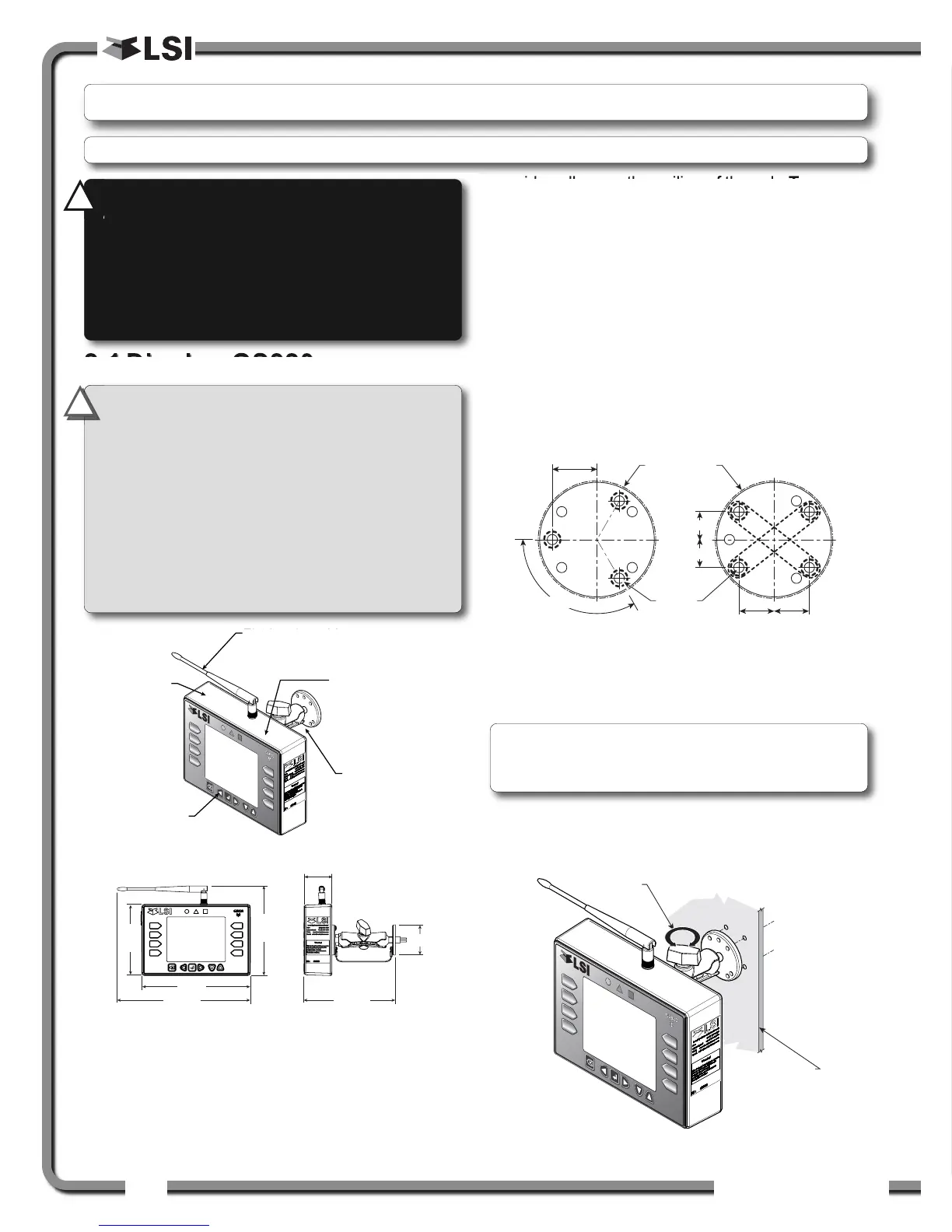

2.1a Mounting Bracket

1. Determine the mounting location; the display

may be installed either inside or outside the

cab. It can be mounted on the dash, on a

sidewall, or on the ceiling of the cab. To ensure

reliable radio communication between

sensors and the GS820, the antenna should

not be in contact with metal and should

have a direct and clear line of sight to the

sensor antenna. The mounting bracket

requires a flat surface of at least 2.5 inches in

diameter on both sides and where the back of

the surface is accessible in order to tighten the

nuts.

2. Drill 1/4 inch boltholes through the mounting

surface with a 1/4 inch bit following either the

two, three, or the four holes configuration.

3. Install the display with bolts. Add washers and lock

nut behind the mounting surface and tighten

sufficiently (bolts, nuts and washers not included).

4. Loosen the wing nut of the bracket arm to adjust

display orientation to facilitate viewing by the

operator and then tighten it back up.

2.

2.

INSTALLATION

INSTALLATION

with dual ball joints.

ø2.5 in. min.

IMPORTANT!

Do not crack or puncture

the membrane fascia. The GS820 display is

splash and rain proof. Waterproofing depends in

part on the integrity of the membrane.

IMPORTANT!

Do not power wash the

display. The GS820 display is not designed to

withstand high-pressure washing devices that

can erode the membrane fascia seal or create

fissures in the membrane fascia. Power washing

the display voids warranty coverage.

!

!

Note: If the nuts are on the outside of the cab,

caulk with silicone between the washers and the

cab to prevent water entry.

WARNING!

Installation must be made in

compliance with

LSI

LSI instructions and using

LSI

LSI supplied components only. Failure to

install all parts, or replacing parts or

components with parts or components not

supplied by

LSI

LSI, may lead to system failure,

serious injury or death.

!

!

Note: Refer to the Operation section for detailed menu navigation instructions for all calibration procedures

Loading...

Loading...