28

28

The GS820 System

The GS820 System

2.12

2.12

List and Trim Angle

List and Trim Angle

Sensor

Sensor

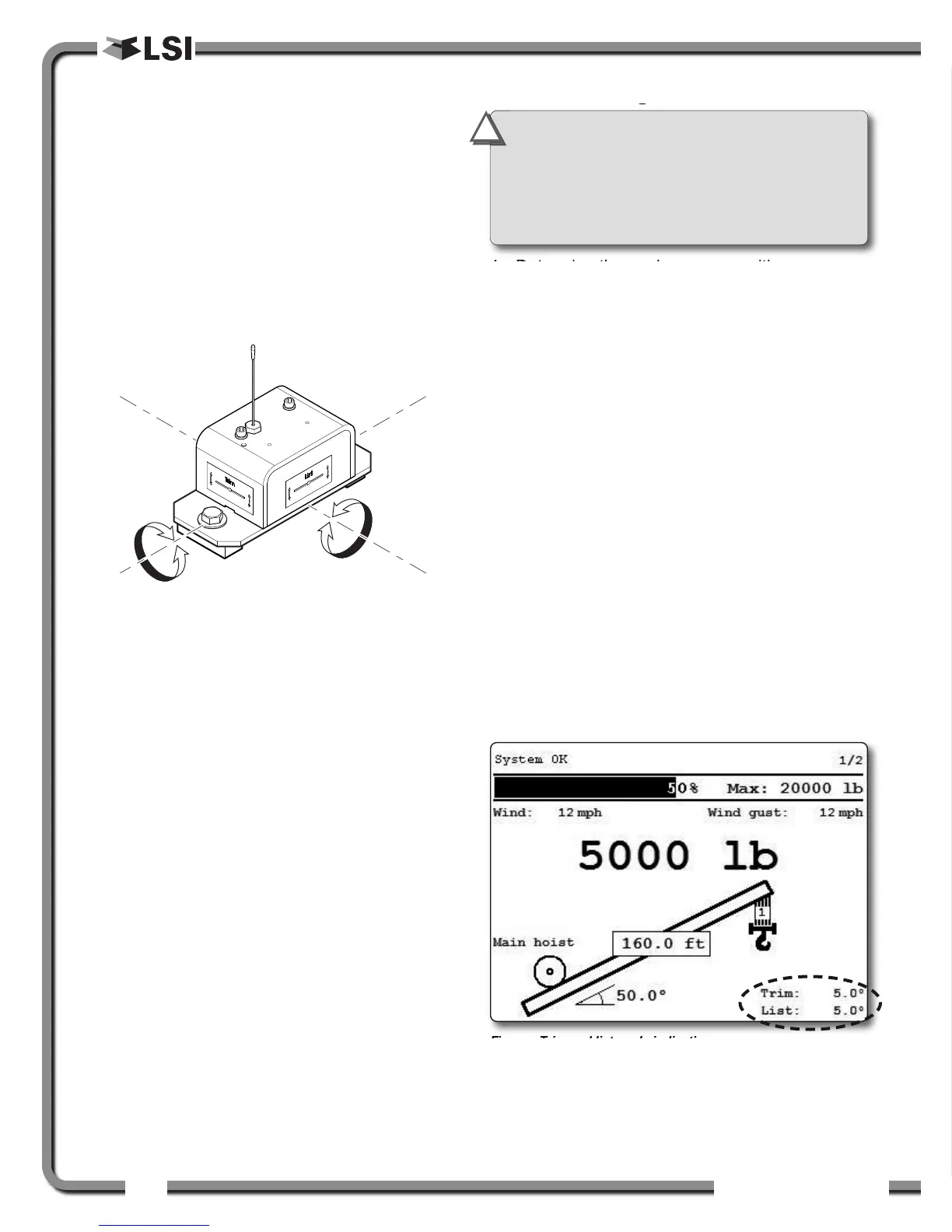

The GS010-03 is a two axis angle sensor designed

to detect both list and trim angle. Minimum and

maximum limits for list and trim angle are

adjustable in the display. The display will generate

an alarm if the limits are exceeded and can be

programmed to generate lockout. Furthermore list

and trim angle can be used to control rated

capacity chart selection where required (example:

barge cranes).

2.12a Programming the GS820 for

List and Trim Indication

For list indication, add the GS010-03 ID number to

the sensor list (menu 4A)) and select the sensor type

“List sensor”.

For trim indication, add the GS010-03 ID number to

the sensor list (menu 4A)) and select the sensor type

“Trim sensor”.

The maximum and minimum angles for list and trim

indication can be adjusted in the limit menu. The

default limits are 10.0° maximum and -10.0°

minimum.

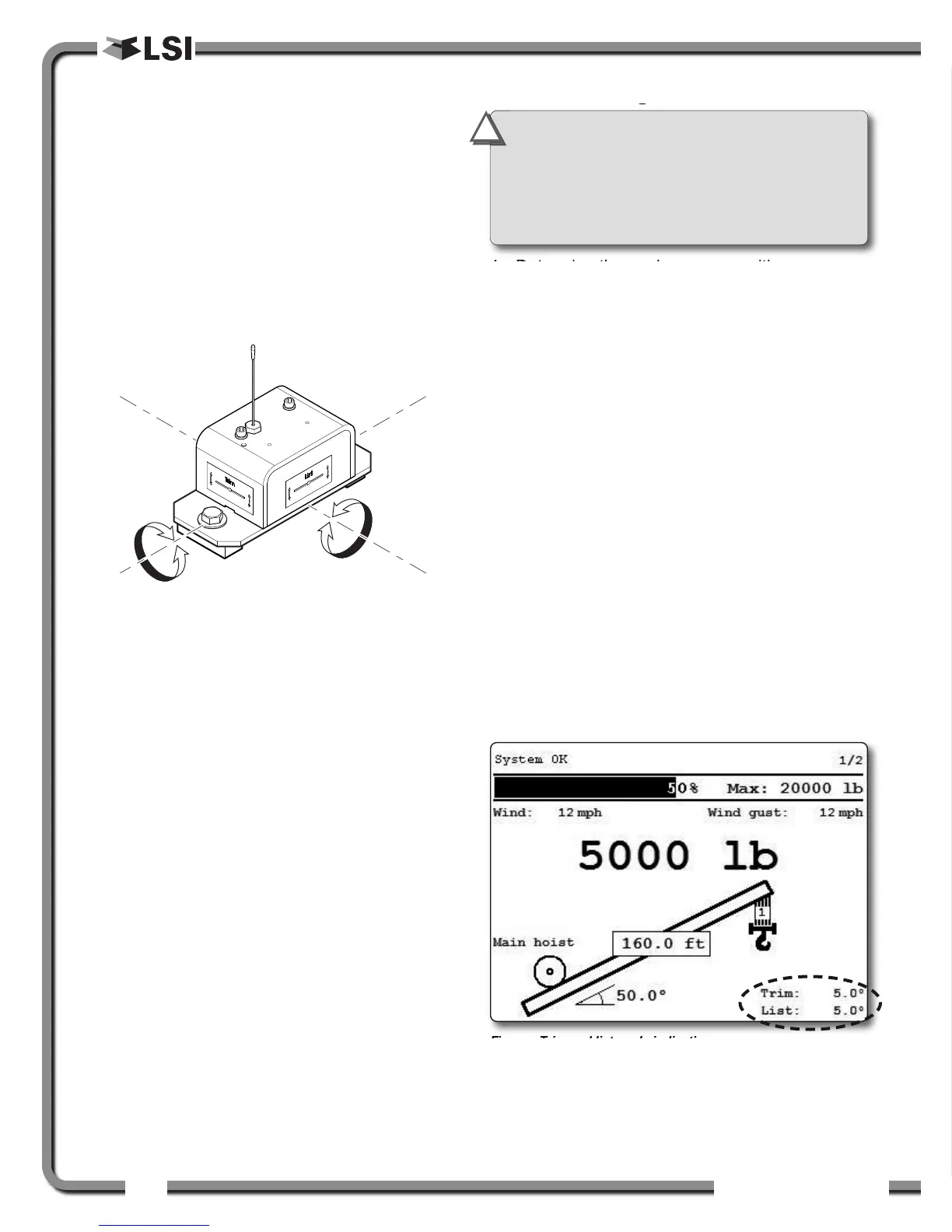

2.12b Mounting Instructions

1. Determine the angle sensor position.

a. The mounting surface should be flat and

known to be level (0°) in both the list and

trim axes.

b. The angle sensor should have a clear line

of sight to the cabin mounted display.

c. The angle sensor should be installed

horizontally, with the antenna pointing up.

d. The list and trim axes are indicated on the

angle sensor, follow these indications to

orient the sensor correctly for accurate list

and trim indication.

e. The angle sensor antenna should not

contact a metal object.

2. Install the welding pads; keep the angle sensor

well removed from the weld site and any

connecting metal objects while welding.

3. Mount the angle sensor to the weld pads with

the screws and washers provided.

4. Verify list and trim angle indication in the

operation display.

Figure: Trim and list angle indication

Figure: List and Trim axes

IMPORTANT!

Remove the angle sensor

from any connecting metal structures or

surfaces when welding the metal lugs to the

mounting surface. Proximity to welding may

cause permanent damage to the angle sensor

and prevent accurate angle indication.

!

!

Loading...

Loading...