Form # 147083 Issue 01/07

88

UNLOADING & ASSEMBLY

974 FLEX HEADER: WING FLOAT SET-UP AND PRE-DELIVERY CHECK

8. With adapter float spring lockout disengaged, wing

float lock pins engaged, and cutterbar

approximately 6” (150 mm) above ground, adjust

wing bell crank linkage to balance wings, as

follows:

NOTE: Fine tuning adjustment of wing bell crank

will be detailed in Step 9.

a) Adjust left wing:

• One of the two pins in the left wing float lock

will be tight and one will be loose.

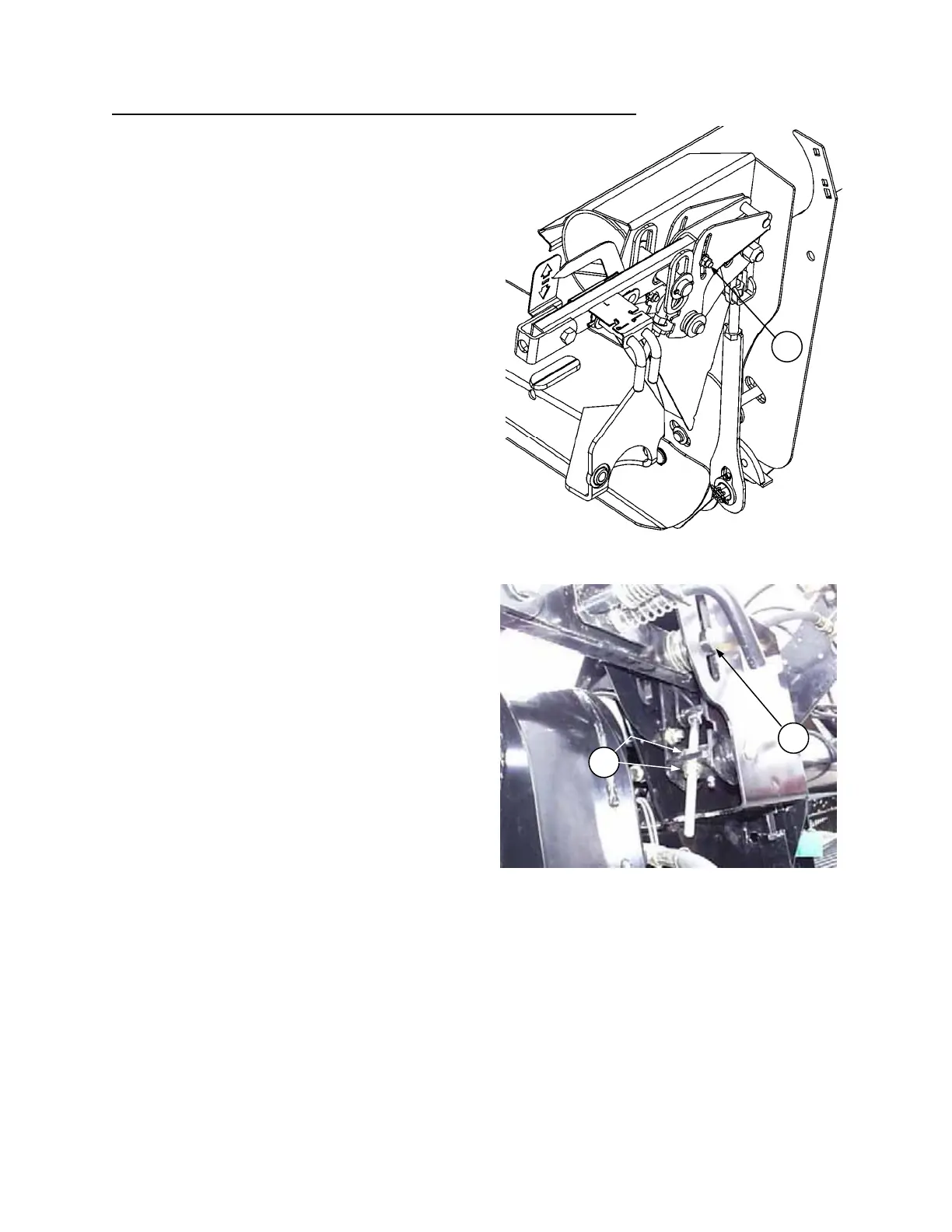

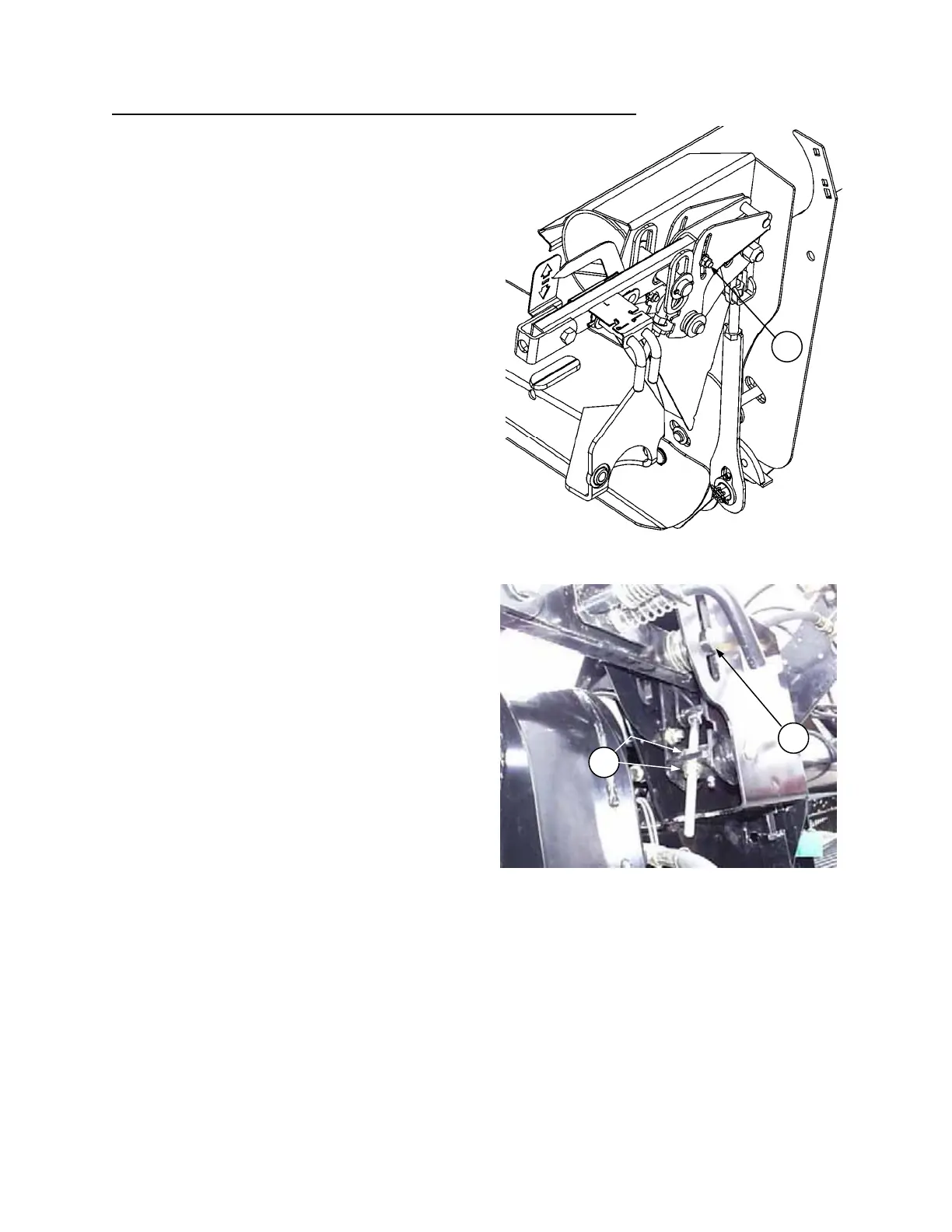

• Loosen nut (N) inside bell crank.

• Adjust bell crank with nuts (P) until both wing

float lock pins are loose.

• Disengage pins in left wing float lock. Float for

right wing remains locked.

• To increase force on divider (making it harder

to pull up), adjust nuts (P) to move top link pin

(M) up. To decrease force on divider (making it

easier to pull up), adjust nuts (P) to move top

link pin (M) down.

• If nuts (P) are difficult to turn, fully lower feeder

house to reduce load on linkage. Return to 6”

(150 mm) cutterbar height when complete.

• Tighten nut (N).

b) Adjust right wing:

• Engage float lock pins in left wing.

Disengage pins in right wing float lock.

• Repeat bell crank adjustment above for right

wing.

c) Disengage pins in left wing float lock and

recheck float balance both sides. Readjust as

necessary.

Continued next page….

P

ADJUST BELL CRANK TO POSITION

TOP LINK PIN

M

LOOSEN NUT TO ALLOW

BELL CRANK ADJUSTMENT

N

Loading...

Loading...