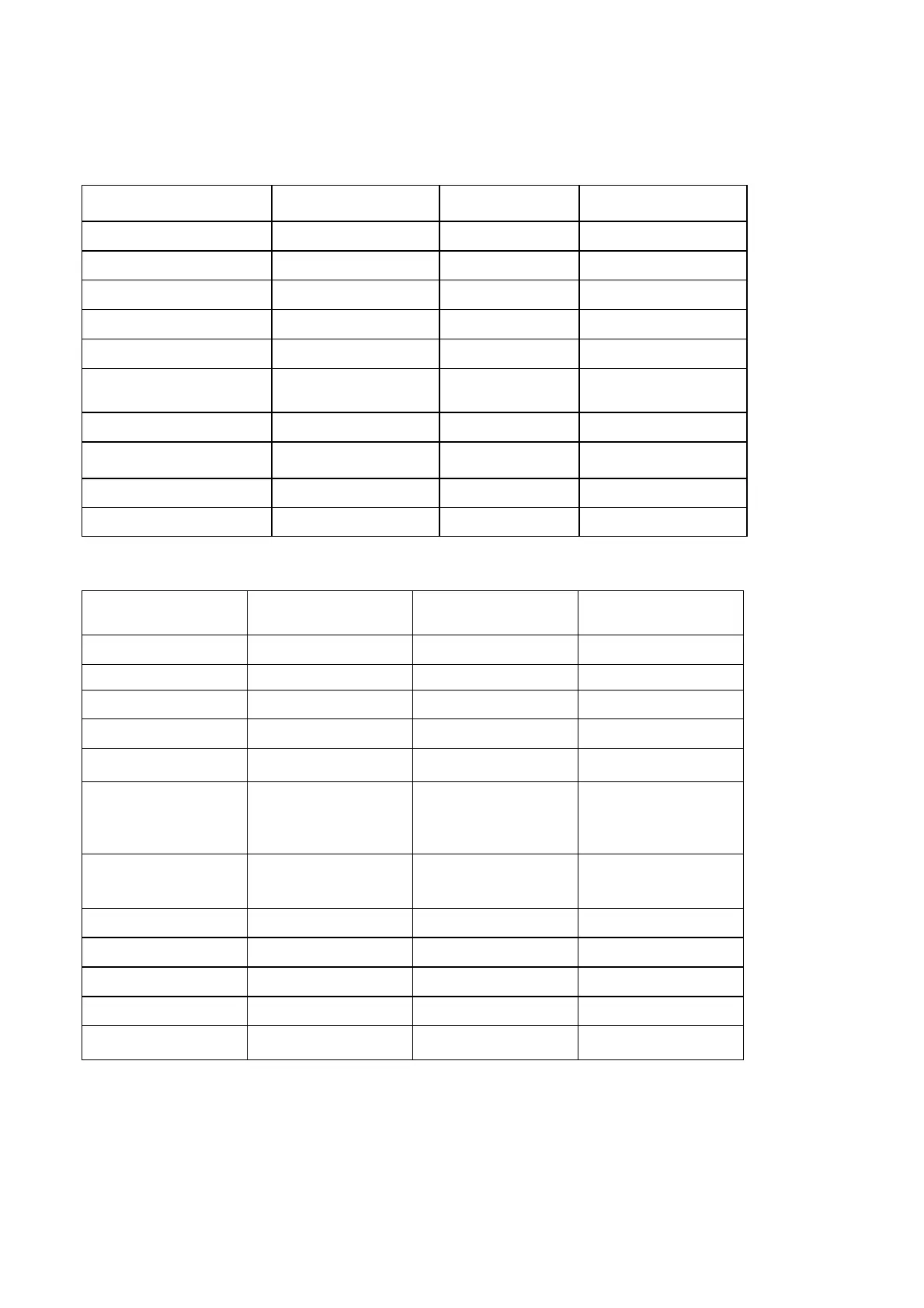

STANDARD OF ADJUSTMENT

1.Tightening Torque of Components

1) Main Body

Tightening Part

Tightening Torque

N.m (ft·lb)

Remarks

Blind plug(Gear case) 5±1(3.6±0.7) M6Χ8 Bolt

Gear case 6±1(4.3±0.7) M5Χ25 Socket head bolt

Gear case retainer bolt 6±1(4.3±0.7) M5Χ14 Socket head bolt

Hanger 3±0.5(2.2±0.4) M5Χ20 Screw

Holder 5±1(3.6±0.7) M5Χ30 Socket head bolt

handle(U-shaped

divisional type)

5±1(3.6±0.7) M5Χ20 Socket head bolt

Safety cover 7±1(5.1±0.7) M6Χ23 Bolt

Tightening

nut

(Cutter

blade)

18±1(1.3±0.7) M8

Control lever 4.5±0.5(3.3±0.4) M6Χ30 Screw

Cutter 3±0.5(2.2±0.4) M5Χ25 Tapping screw

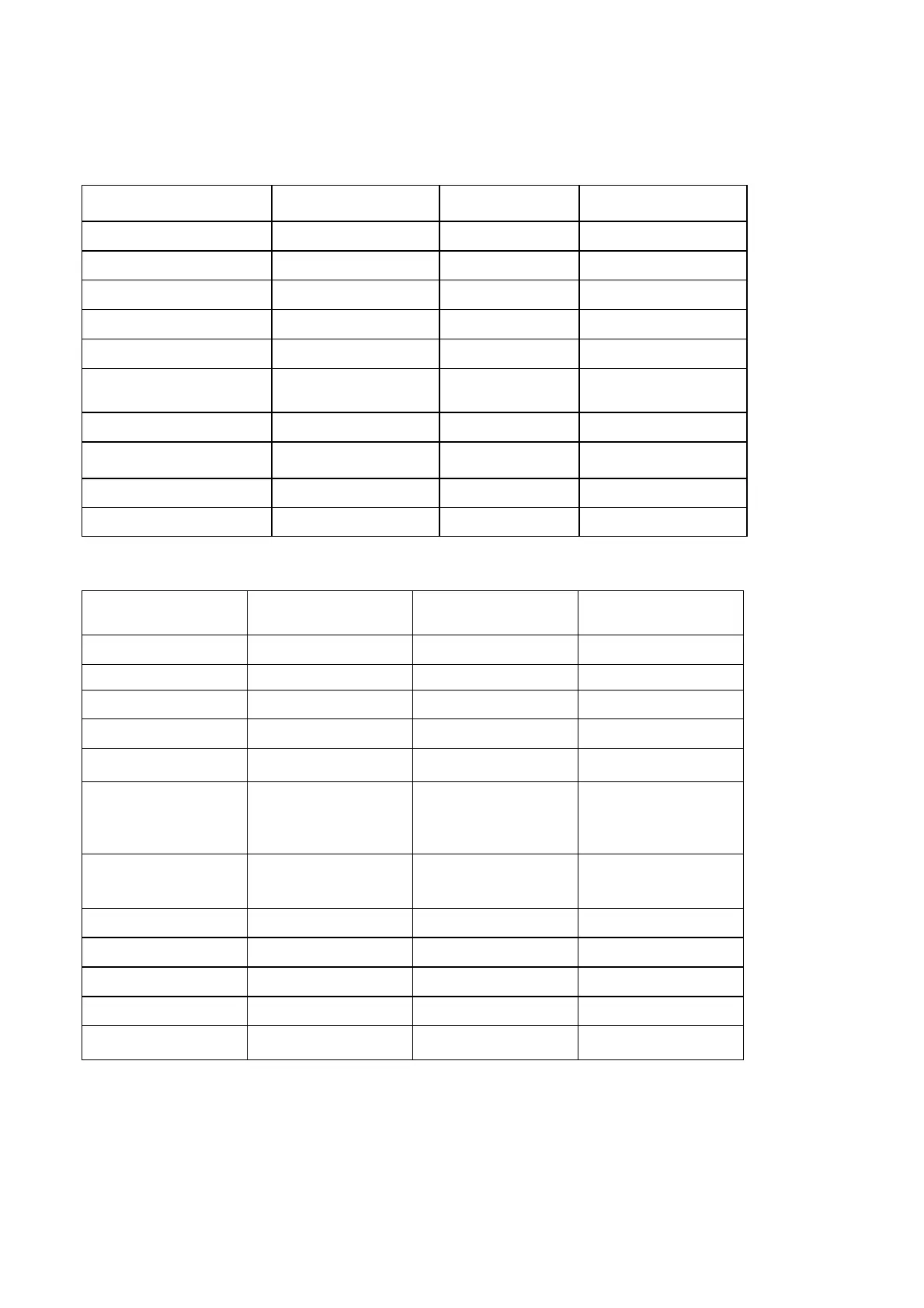

2) Engine

Tightening Part

Tightening Torque

N.m(ft·lb)

Screw Diam.

ΧLength

Remarks

Crank 6±0.5(4.3±0.4) M5Χ30 Screw

Cylinder 6±0.5(4.3±0.4) M5Χ20 Screw

Flywheel 9±1(6.5±0.7) M6 Tighten with clutch

Ignition 2.5±0.5(1.8±0.4) M4Χ20 Screw

Spark plug 18±3(1.3±0.7) M14

Muffler

6±0.5(4.3±0.4)

M5Χ50

*(Use anaerobic

high-strength

Insulator

4.5±0.5(3.3±0.4)

M5Χ25

high-strength sealants)

Carburetor 2.5±0.5(1.8±0.4) M5Χ63 Screw

Engine cover 4.5±0.5(3.3±0.4) M5Χ20 Screw

Starter cover 4.5±0.5(3.3±0.4) M5Χ20 Screw

Air cleaner cover 1—1.5(0.7—1.1) M5Χ20 screw

Choke lever 0.3—0.4(0.2—0.3) M3Χ10 Tapping screw

*use this or its equivalent.

Loading...

Loading...