4

5

6

7

Reworking valve seat

94

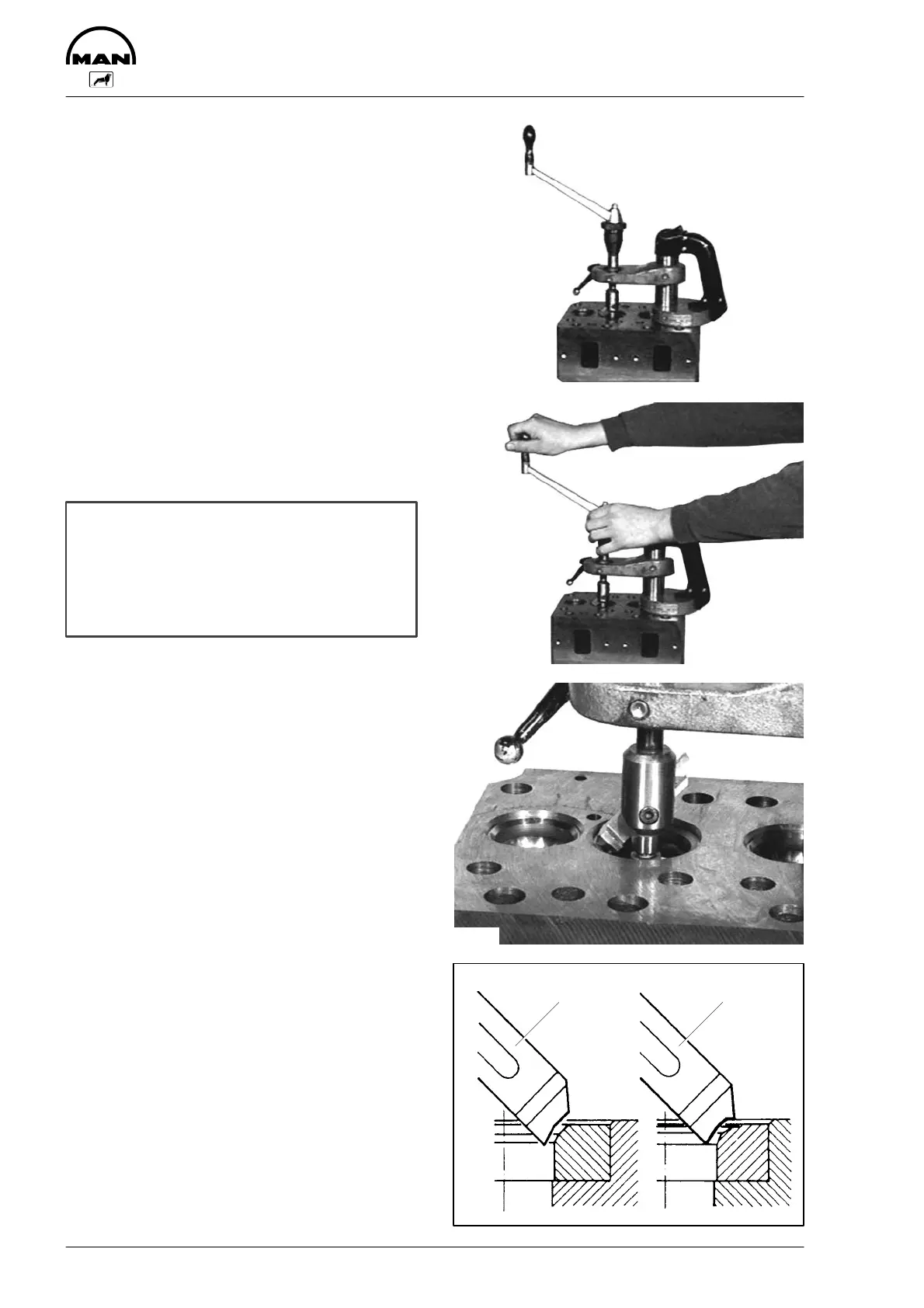

Fig. 4

Release Jaccard lever, place magnetic flange flush

on the clamping plate and set the height so that

the tool does not contact the valve seat.

Set toggle switch to position 1.

Tighten the Jaccard lever.

Fig. 5

Machine the valve seat by turning the driving crank

evenly in clockwise direction and simultaneously

operating the feed nut.

Caution:

During the machining process turn the driv-

ing crank vigorously and evenly but under no

circumstances against the direction of turn-

ing, as otherwise the carbide cutting edge

may break.

Fig. 6

Once the valve seat has been expertly machined,

reduce the working pressure of the tool by 2-3 rev-

olutions without feed motion.

During these revolutions turn the feed nut 2-3 rev-

olutions back.

Press toggle switch briefly to position 2 to lift the

magnetic field.

Now move the whole Mira unit out upwards and

insert it into the next valve guide, repeating the

centering operation.

Use the same tool settings for all intake and all

exhaust valve seats (see below).

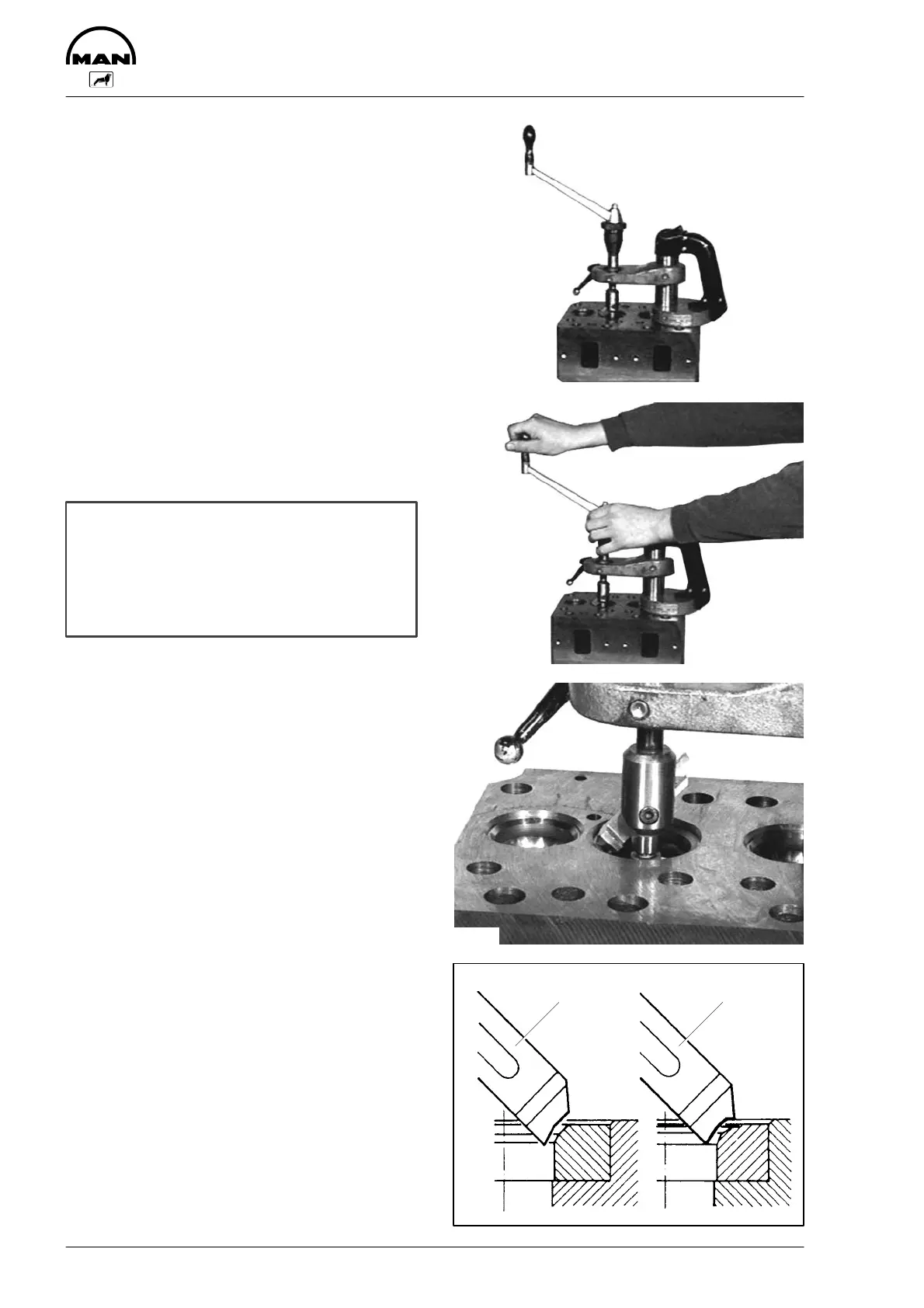

Fig. 7

Observe specified seat angle.

1 Exhaust, total angle: 90_, tool setting: 45_

2 Inlet, total angle: 120_, tool setting: 30_

Repeat the chip-removing machining process until

the valve seat is clean and free of pores.

3361

3362

3363

2819

21

Loading...

Loading...