HYDRAULIC SYSTEM 14000 SERVICE MANUAL

2-16

Published 09-10-14, Control # 065-24

Swing Brake

Perform the following check in an area where the crane can

be swung without interference.

1. Scroll to swing diagnostic screen to monitor swing

component icons.

2. Turn off swing park and attempt to swing the crane by

moving control handle in both directions.

3. Crane must swing freely.

4. Swing screen should indicate that swing park brake is

released.

5. Bring upperworks to a complete stop, move control

handle to off, turn on swing park.

6. Swing handle should be inoperable.

7. Swing screen should indicate no handle or pump

commands and that swing park brake is applied.

Travel Brakes

Perform the following check in an area where the crane can

be traveled without interference.

1. Scroll to travel diagnostic screen to monitor travel

component icons.

2. Turn off travel park and attempt to travel the crane by

moving control handles in both directions.

3. Crane must travel freely.

4. Travel screen should indicate that travel park brakes are

released.

5. Turn on travel 2-speed. Travel speed should increase

and travel screen should indicate that 2-speed is on.

6. Bring upperworks to a complete stop, move control

handles to off, and turn on travel park.

7. Travel handles should be inoperable.

8. Travel screen should indicate no handle or pump

commands and that travel park brakes are applied.

Back Hitch Pins

Access setup remote control in left side enclosure and

connect to node 3 controller, connector W36.

1. Fully engage and disengage pins three to four times to

remove air from cylinders.

2. Scroll to Diagnostic screen to verify that 350 psi (24 bar)

is present when pins are fully engaged.

Speed Checks

Travel Speed

Perform the following check in an area where the crane can

be traveled without interference.

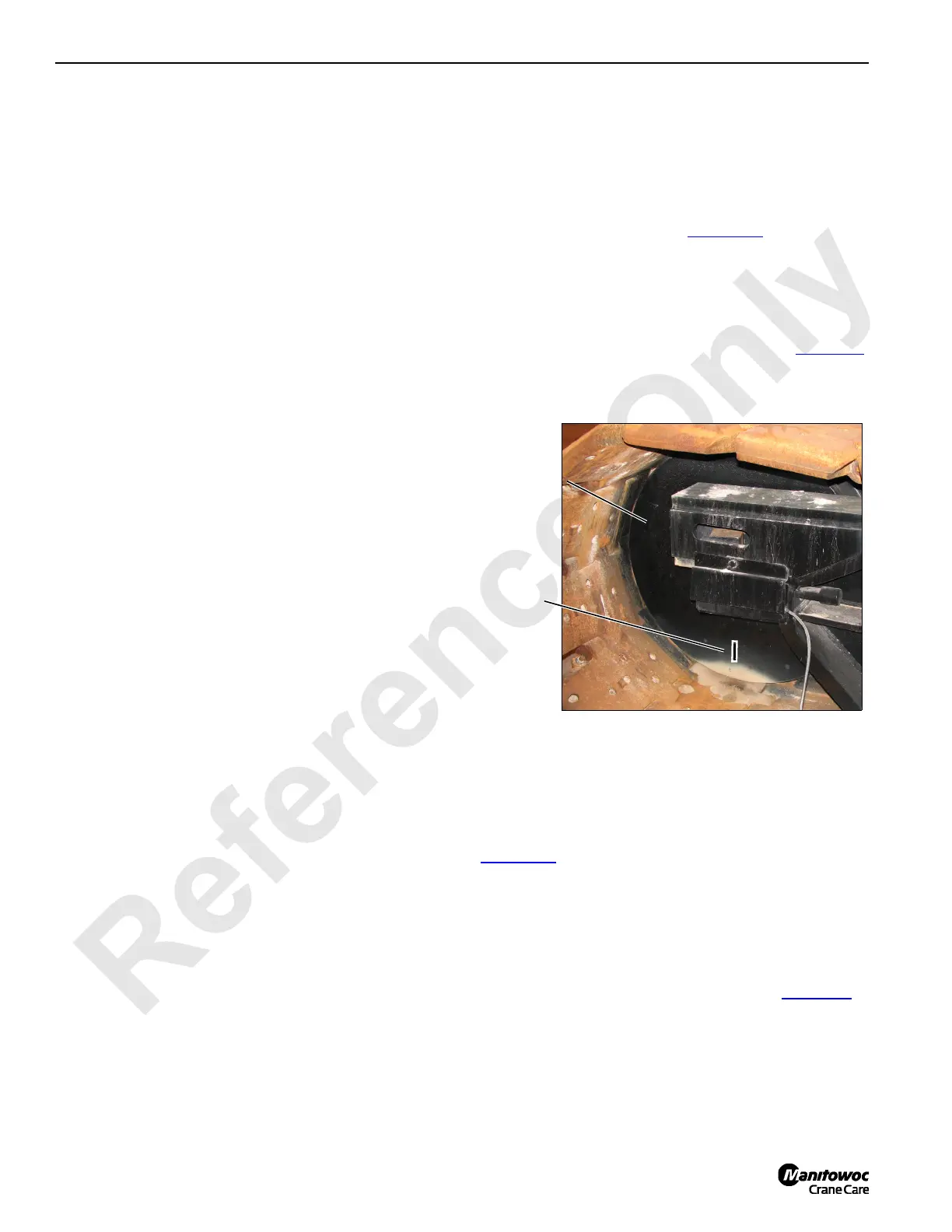

1. Put a timing mark on crawler roller at front of one crawler

and at rear of other crawler (Figure 2-16

).

2. Start and run the engine at high idle.

3. Push both crawler control handles fully FORWARD to

travel the crane at full speed.

4. Have an assistant count number of revolutions timing

marks make — must be within range given in Table 2-10

.

5. If speed is not within specified range, contact Manitowoc

Crane Care Lattice Team.

Swing and Drum Speeds

Perform the following check in an area where the crane can

be swung without interference.

Check operating speed on the diagnostic screens

(Figure 2-15

) for swing and each drum with:

• Engine running at high idle.

• Control handles moved fully forward and back.

• No load.

• No rope on drums.

Speeds must be within the ranges specified in Table 2-10

. If

proper speeds are not indicated, contact Manitowoc Crane

Care Lattice Team.

FIGURE 2-16

Crawler

Roller

Timing

Mark

P2363a

Loading...

Loading...