Manitowoc Published 09-10-14, Control # 065-24 5-5

14000 SERVICE MANUAL HOISTS

SPEED SENSOR ADJUSTMENT

General

The hydraulic motor for each hoist drum has a speed sensor.

Each speed sensor monitors rotational speed and direction

of the corresponding function’s motor. The sensor sends a

signal to a remote node controller that transmits information

to the crane’s master controller. The master controller uses

this information to control crane functions.

Speed Sensor Replacement

When removing the speed sensor from a motor, be careful to

contain the hydraulic fluid that will drain from the motor. After

installing a new sensor, add clean hydraulic oil to the level of

the motor’s top case drain port before starting the engine.

Speed Sensor Adjustment

Speed sensors are set at the factory and should not need

adjustment, unless replaced.

1. Bring corresponding function to a complete stop, land

suspended load if load drum is being serviced, and

PARK function.

2. Remove faulty sensor. Do not connect sensor cable to

crane wire harness until initial adjustment is made.

3. Loosen lock nut and carefully turn sensor in (clockwise)

by hand until it gently contacts speed ring inside motor.

4. Back sensor out one turn or more until notch is

positioned 180° from motor shaft (facing outboard side

of motor).

5. Connect sensor cable to crane wire harness.

6. Operate drum motor and check for a steady drum speed

(RPM) signal on corresponding drum’s diagnostic

screen in cab.

If necessary, turn sensor out slightly until drum speed

(RPM) is steady at low and high RPM.

7. Hold sensor in position and securely tighten lock nut.

WARNING

Burn Hazard!

Hot oil will drain from motor port when sensor is removed.

Wait for hydraulic oil to cool before removing sensor.

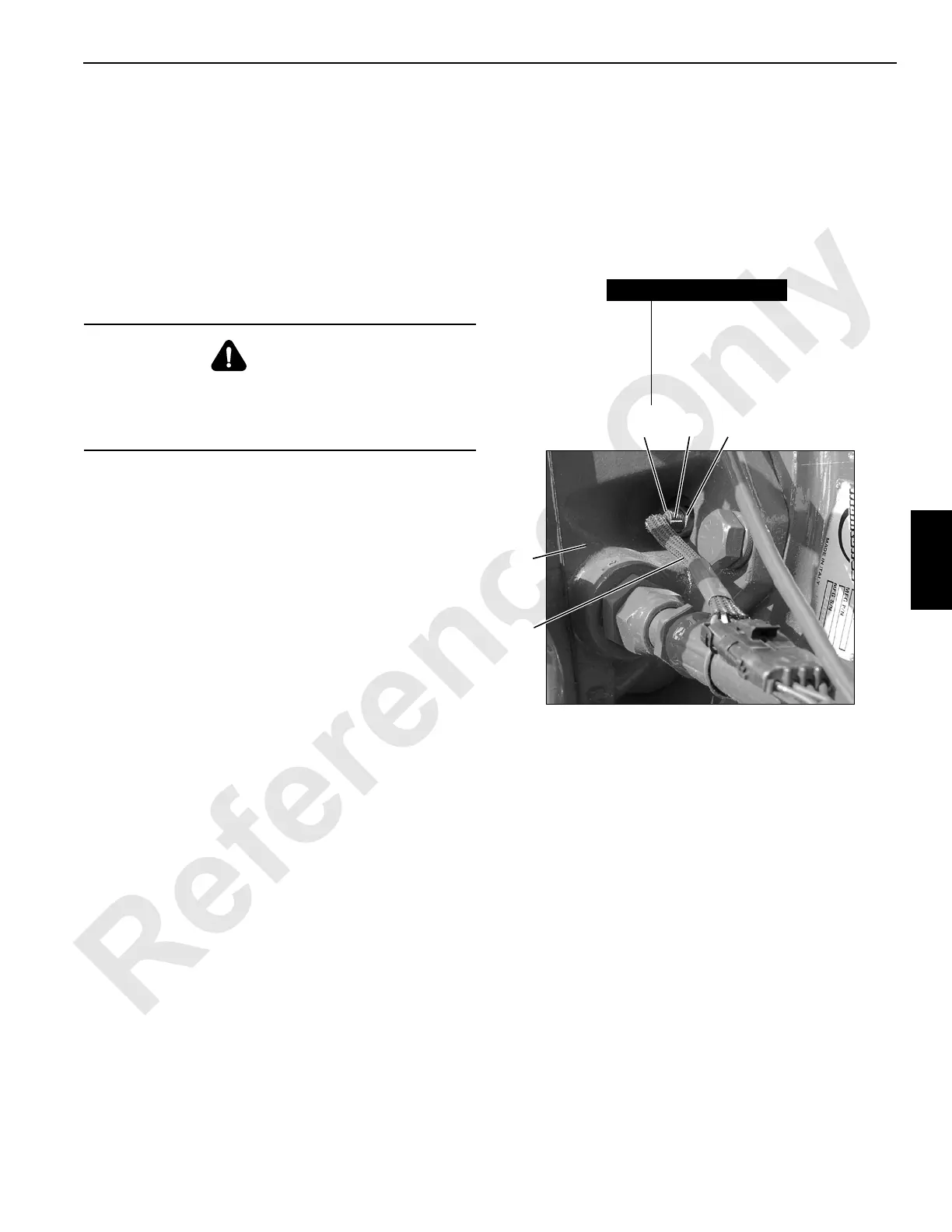

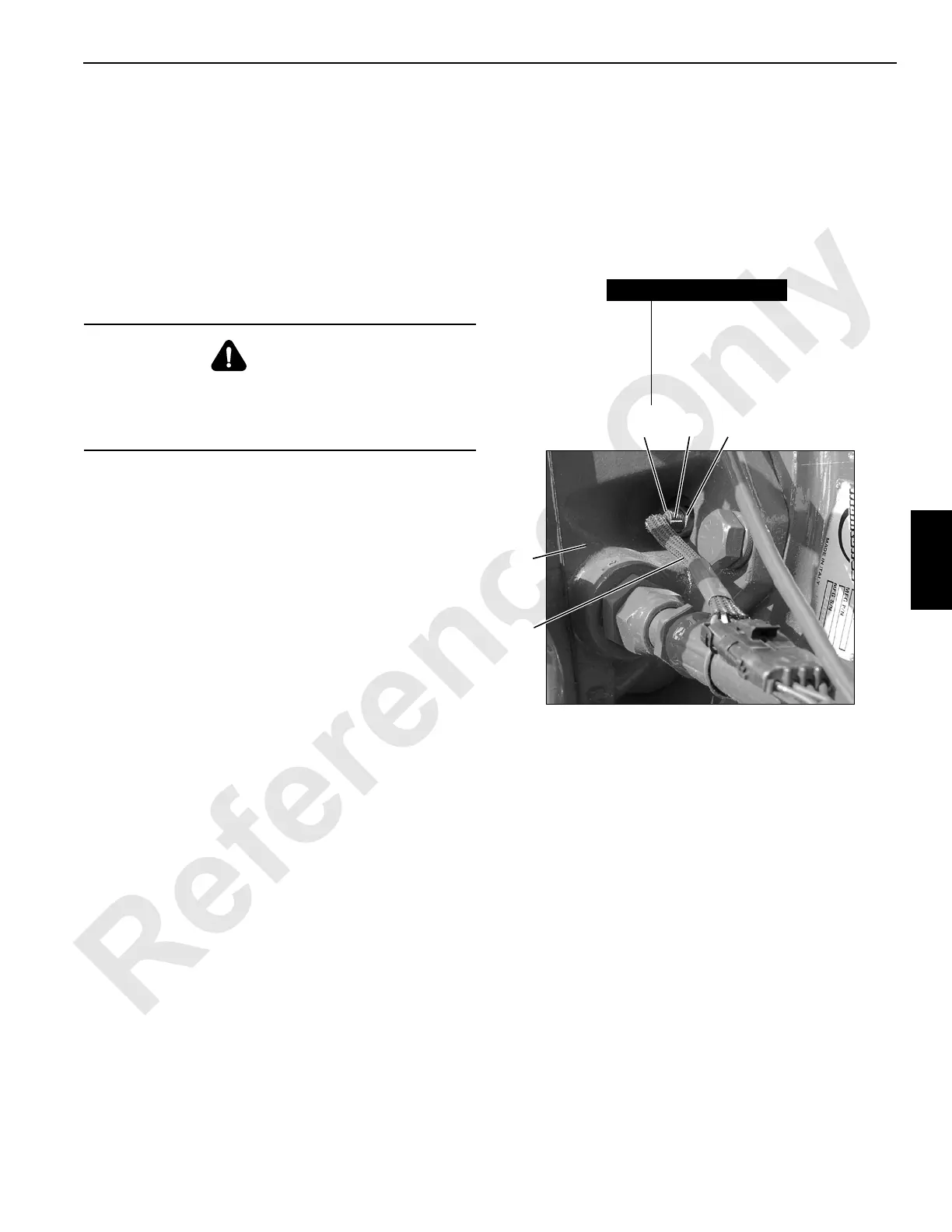

P2196

Typical Speed Sensor Installation

at Drums 1, 2, 3 and 4

FIGURE 5-4

Item Description

1 Speed Sensor

2Notch

3 Lock Nut

4Cable

5 Motor

4

1

5

2

3

Loading...

Loading...