INTRODUCTION 14000 SERVICE MANUAL

1-22

Published 09-10-14, Control # 065-24

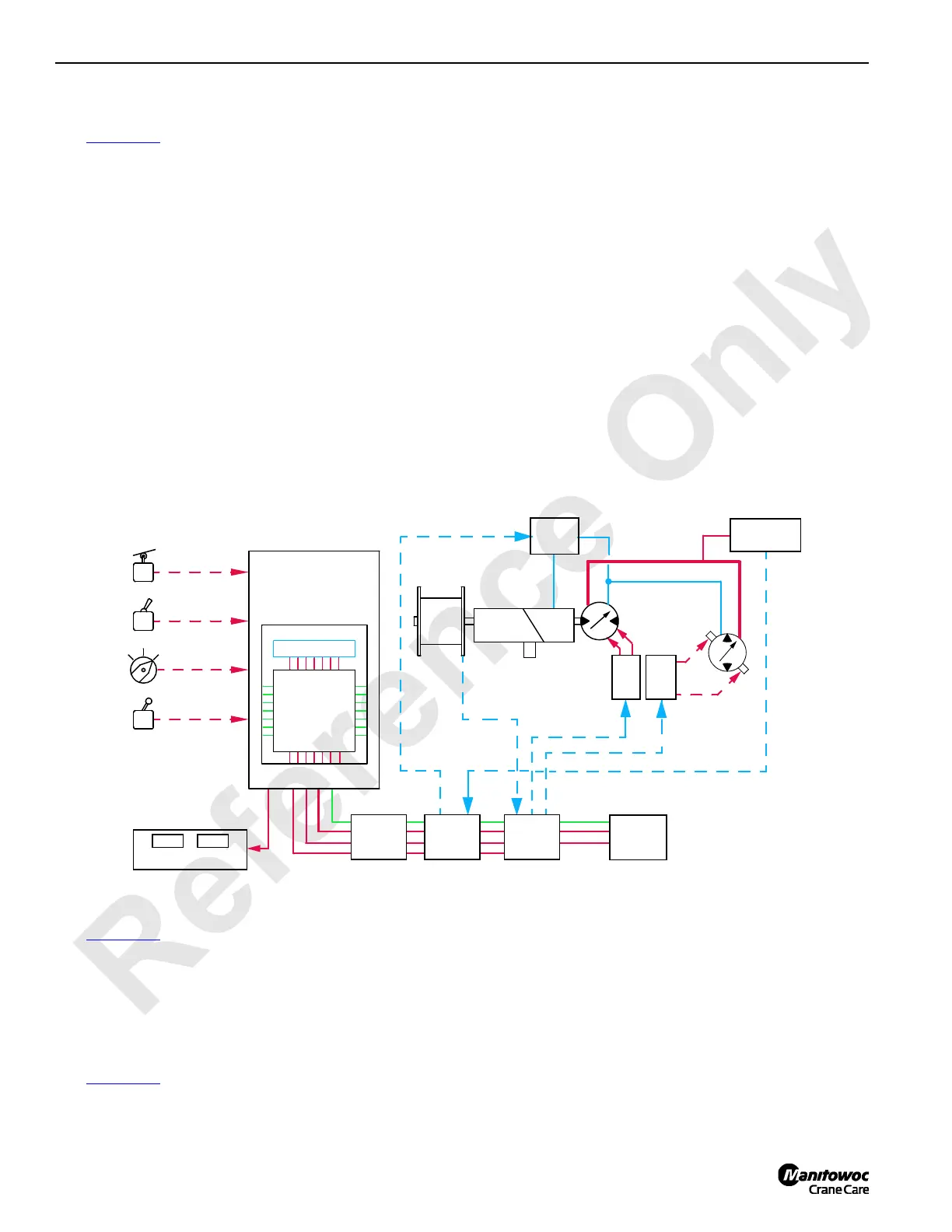

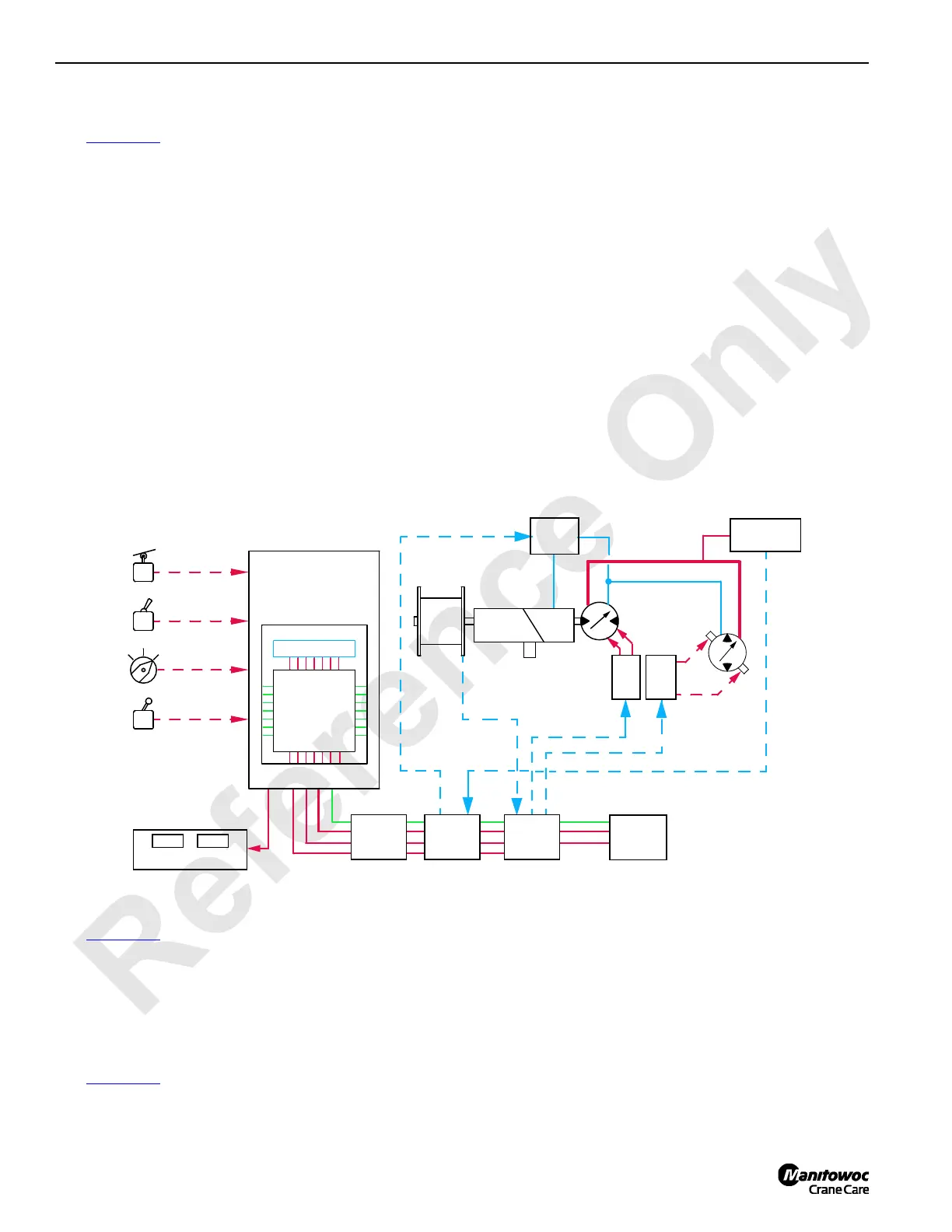

ELECTRICAL CONTROL SYSTEM

See Figure 1-13 for the following procedure.

The crane’s boom, load lines, swing, crawler tracks, and high

pressure accessory components are controlled electronically

with the EPIC (electrical processed independent control)

with CAN-bus (controller area network) technology. The 24

volt CAN-bus programmable controller system uses remote

nodes that contain controllers. Node controllers

communicate with node 1 (master) controller by sending

data packets over a two-wire bus line. Data packets are

tagged with addresses that identify system components.

Node 1 controller compares these input data packet signals

with programming directives and data information. Node 1

controller then provides appropriate output voltage

commands to remote node controllers.

Each node controller receives and sends both analog and

digital input/output voltages. Analog input/output voltages

are either AC or DC variable voltages or currents. Digital

input/output voltages are zero volts (no voltage) or nominal

24 volts.

Node controllers use the binary system. The binary system is

based on binary multiples of two and only recognizes 0 = off

or 1 = on. Basic counts of this system are exponents of the

number two. These exponents are formed in words, called

bytes, of eight numbers each. The eight numbers are 1, 2, 4,

8, 16, 32, 64, and 128 for an 8-bit controller or a combination

of up to 255 bytes. These bytes represent electrical inputs/

outputs to node 1 controller.

Remote nodes on the boom monitor the boom, luffing jib, or

fixed jib components and input the information to node 1

controller. Boom components include angle sensors, block-

up limits, wind speed, and load pin sensors. The mast angle

position is also monitored.

The system nodes controllers are listed below:

Node 1 — Master (Front Console) Cab Controls

Node 2 — Handles and Cab Controls

Node 3 — Drums 1, 2, 3, Limits, and Accessories

Node 4 — Pumps, Sensors, and Drum 4

Node 0 — Engine

RIN (Remote Input Node) Boom

Display Screens

See Figure 1-13 for the following procedure.

The display screens contains the Rated Capacity Indicator/

Limiter display and main display. Use the menu screens to

selected Rated Capacity Indicator/Limiter and crane

functions.

Electrical Power to Operator’s Cab

See Figure 1-14 for the following procedure.

When key-operated engine switch is in STOP position,

voltage is available to operate dome light switch, and radio/

clock. When key-operated engine switch is placed in RUN

position, power is available to the following relays:

• Engine starter (SS) and grid heater (HR)

• CAN-bus system power relay (CAN PWR)

• CAN-bus system ground relay (CAN GND)

• Cab power relay (CAB PWR). When cab power relay is

enabled, power is available to operate crane controls.

• Air conditioning system relay (A/C COMP)

FIGURE 1-13

Monitoring

Voltages Out

Command Voltages In

Node 2

Node 1

Master Controller

RIN

(Boom)

Node 3

Node 4

Processing

Memory

Switches

Brake

Valve

Drum

Speed

Drum

Pressure

Sender

Motor

Pump

Selectors

Limit

Switches

Control

Handles

Voltages to

Counts to

Voltages

Limit Switches

Display Screens

Brake

Gear

Reducer

14CSM1-103

PCP

EDC

Loading...

Loading...