HOISTS 14000 SERVICE MANUAL

5-20

Published 09-10-14, Control # 065-24

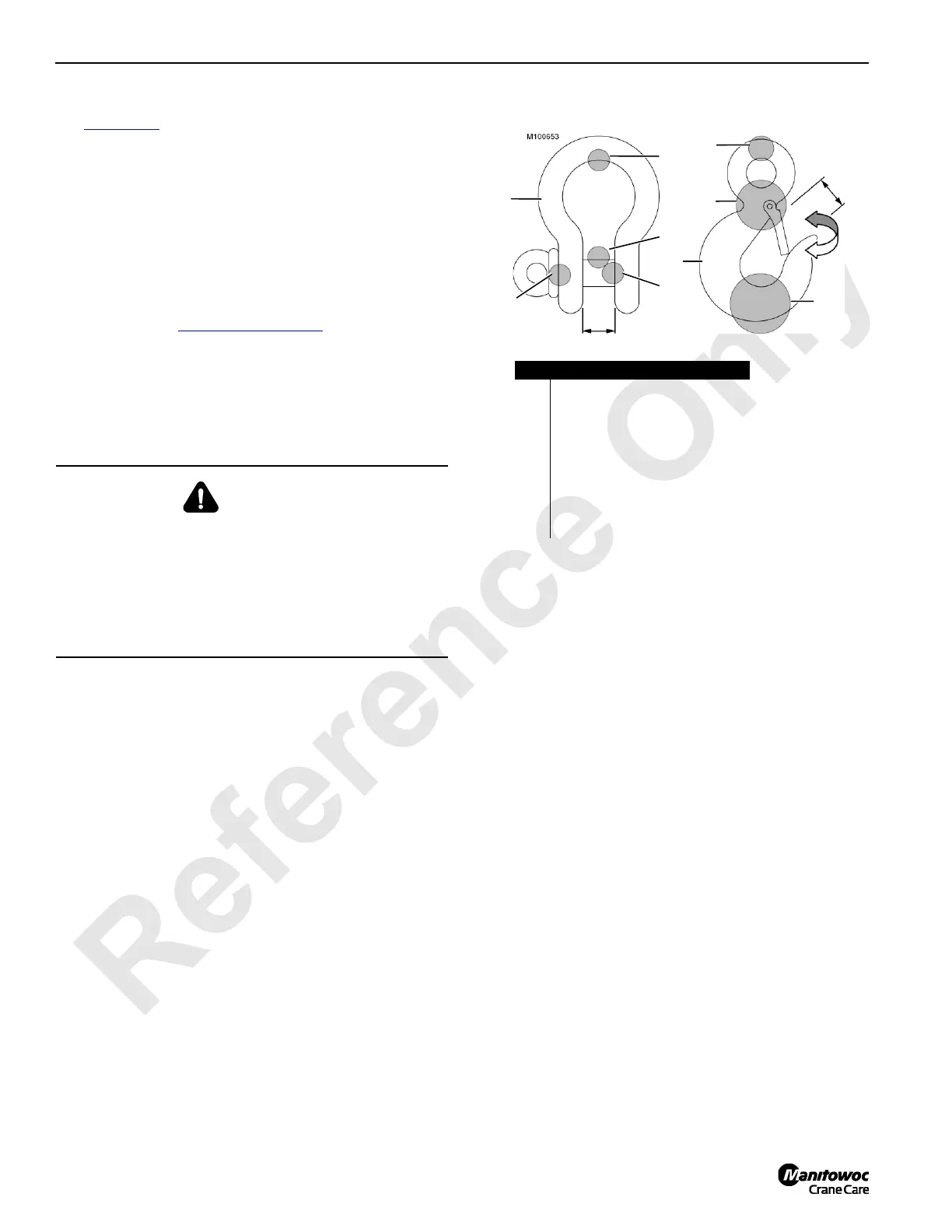

12. Inspect each hook and shackle for damage as shown in

Figure 5-19

.

13. See the ASME B30-10 Standard for specific hook

replacement guidelines. The standards are available as

follows:

•Mail — ASME, 22 Law Drive, Fairfield, New Jersey,

0700-2900

• Toll free phone – US & Canada 800-843-2763,

Mexico 95-800-843-2763, Universal 973-882-1167

•Fax — 973-882-1717 or 973-882-515

•E-mail — infocentral

@asme.org).

14. Contact the supplier of your hooks, shackles, blocks,

and other rigging for repair instructions.

15. Check each hook and shackle at least yearly for cracks

using a dye penetrant test, MAG particle test, ultrasonic

test, or by X-ray.

WARNING

Falling Load Hazard!

To prevent load from dropping due to hook or shackle

failure, do not attempt to repair cracks in hooks and

shackles by welding. Furthermore, do not weld on any

load bearing component unless proper welding methods

are used (contact Manitowoc Crane Care for material and

welding specifications).

FIGURE 5-19

2

3

4

4

2

6

8

Item Description

1 Shackle

2 Check for Wear and Deformation

3

Check for Wear and

Straightness

4 Check that Pin is Always Seated

5Hook

6 Check that Hook is Not Twisted

7 Check for Cracks and Twisting

8 Check for Wear and Cracks

7

1

5

7

Loading...

Loading...