Manitowoc Published 05-16-17, Control # 233-03 4-15

999 SERVICE/MAINTENANCE MANUAL BOOM

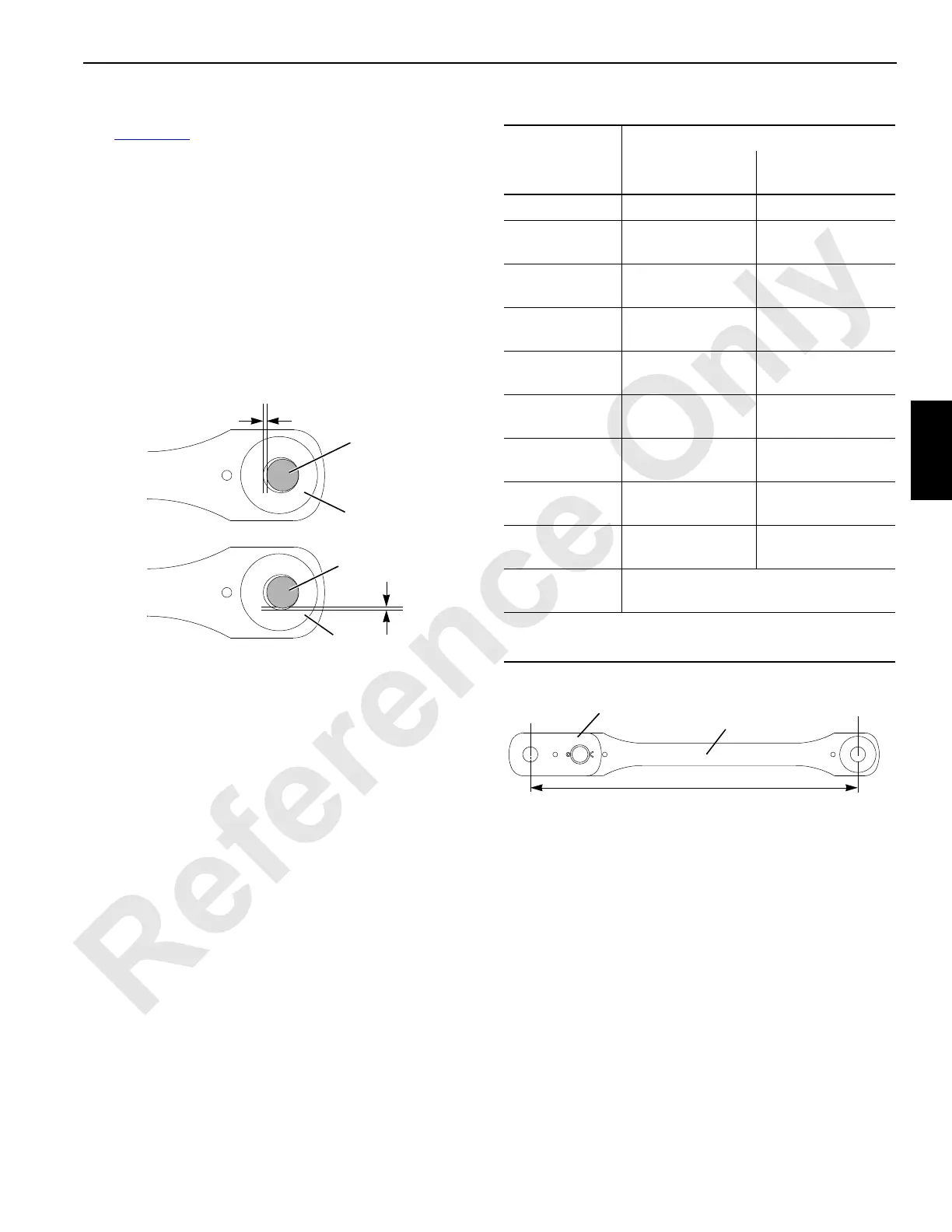

Elongated Hole

See Figure 4-15 for the following procedure.

1. Insert pin into hole.

2. Push pin tight against edge of hole along horizontal

center line. Measure dimension between pin and hole

(View A).

3. Push pin tight against edge of hole along vertical center

line. Measure dimension between pin and hole (View B).

If dimensions A and B are not identical, hole is

elongated. Remove strap from service.

If two dimensions are identical, but greater than 0.030 in

(0,8 mm), contact factory Service Department.

Length

Pin

Strap

Pin

Strap

B

View A

View B

A

A1086

FIGURE 4-15

Elongated Holes

Strap Length

(L)

ft (m)

Maximum Deviation Allowed

1 to <2 in (25 to

<51 mm) Thick

2 to <4 in (51 to

<102 mm) Thick

<3 (<0,9) 0.17 (4,3) 0.50 (12,7)

3 to <4

(0,9 to <1,2)

0.63 (15,9) 0.56 (14,3)

4 to <5

(1,2 to <1,5)

0.75 (19,1) 0.70 (17,5)

5 to <6

(1,5 to <1,8)

0.80 (20,6) 0.75 (19,1)

6 to <7

(1,8 to <2,1)

0.88 (22,2) 0.75 (19,1)

7 to <8

(2,1 to <2,4)

0.94 (23,8) 0.75 (19,1)

8 to <9

(2,4 to <2,7)

1.0 (25,4) 0.75 (19,1)

9 to <10

(2,7 to <3,0)

1.0 (25,4) 0.88 (22,2)

10 to <12

(3,0 to <3,7)

1.0 (25,4) 1.0 (25,4)

≥12 (≥3,7)

Deviation not to exceed 1 in (25,4 mm)

in any 12 ft (3,7 m) length of strap

< = less than

≥ = equal to or greater than

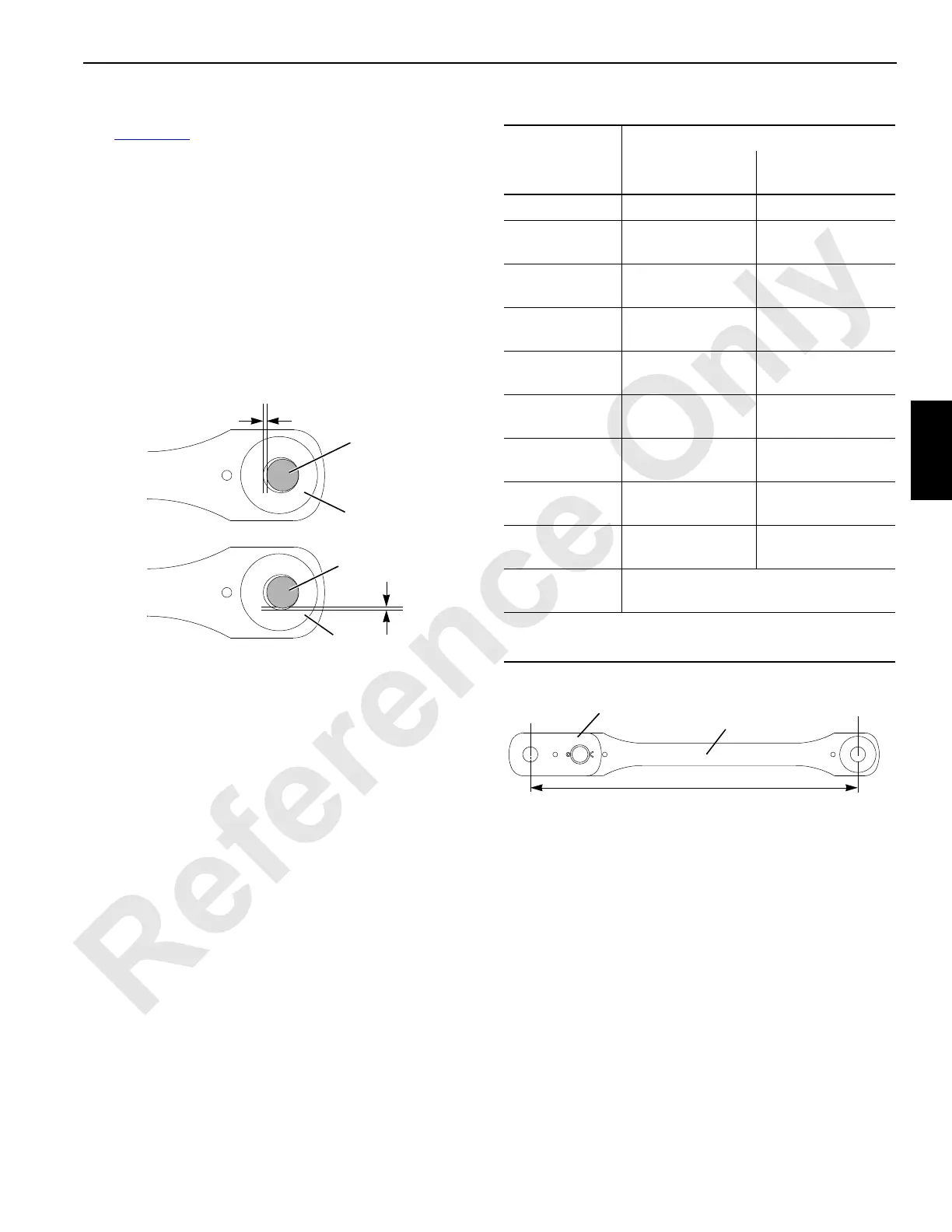

FIGURE 4-16

Measure to check length. See appropriate rigging drawing in

Operator Manual for original length. Strap length includes

connecting link. If change in length is detected, remove strap from

service.

Length

Strap

Link

A1086

Loading...

Loading...