Manitowoc Published 05-16-17, Control # 233-03 1-17

999 SERVICE/MAINTENANCE MANUAL INTRODUCTION

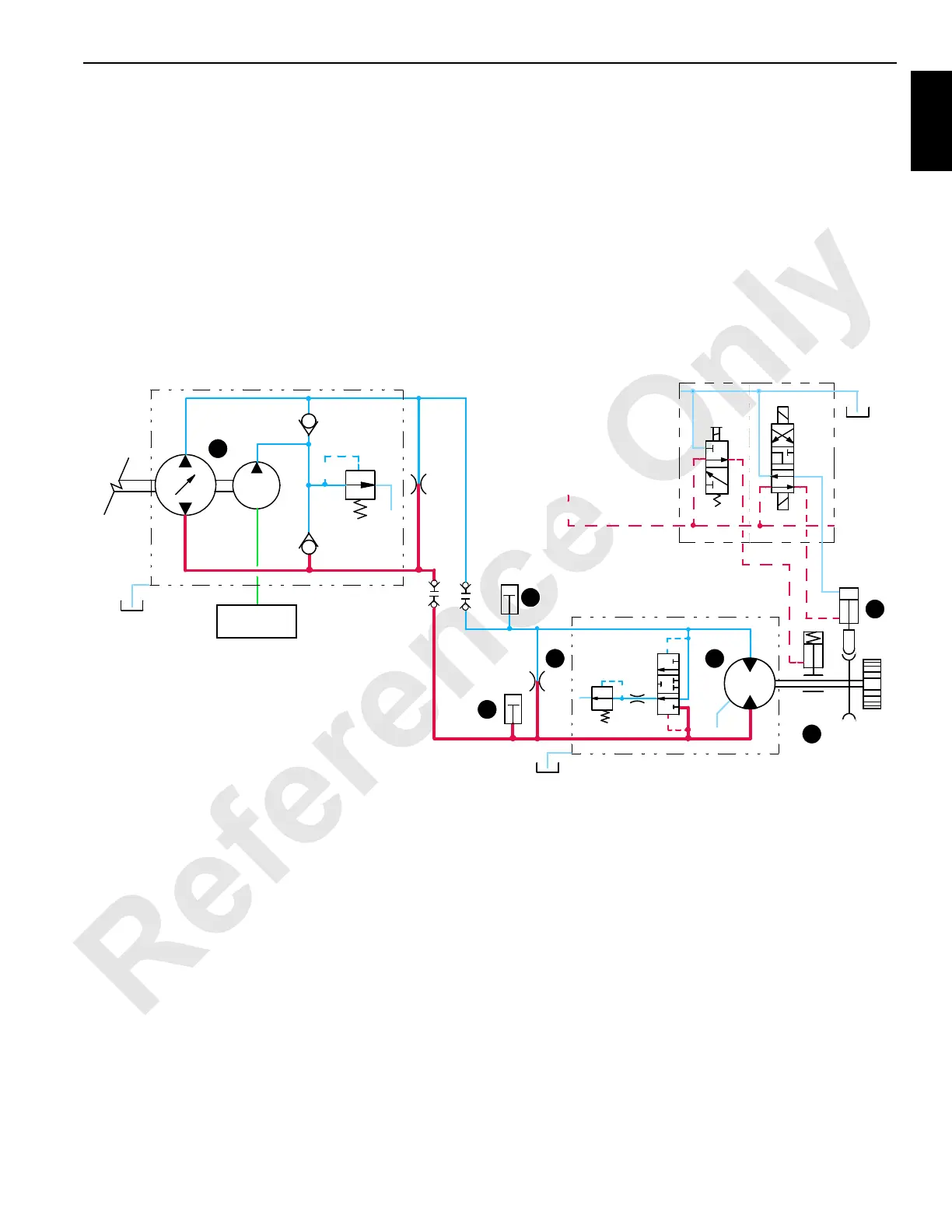

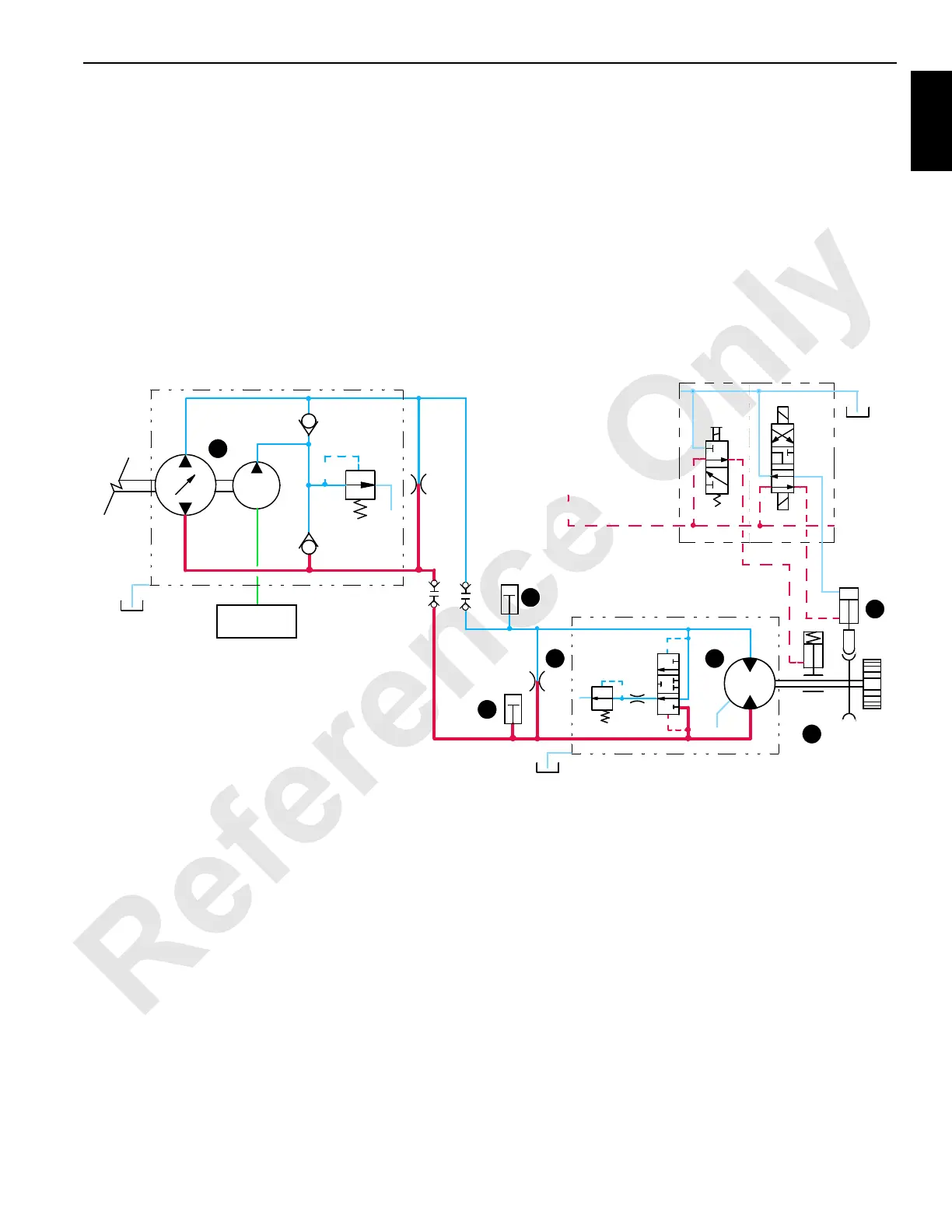

When swing handle is moved to right, an input voltage of 5

volts or less is sent to the PC. The PC sends a positive

output voltage to swing pump EDC. Swing pump swashplate

tilts relative to swing handle movement. Fluid flows from

swing pump port A to swing motor port A, moving rotating

bed to the right.

As swing handle is moved to neutral position, the PC sends

an output signal to adjust swashplate to centered position.

When in a swinging motion, the preferred way to stop or slow

crane is to move swing handle beyond center in the opposite

direction. This allows rotating bed to gradually stop.

Swing Holding Brake Switch

Swing holding brake switch (10) on side of swing handle,

holds rotating bed in position (applies swing park brake) for

short periods when operating. To prevent damage to swing

system, swing holding brake switch must only be applied

when crane is at a standstill.

When swing holding brake switch is pressed in and held,

circuit to swing brake release solenoid HS-8 is opened,

allowing fluid to exhaust to tank and brake spring-applies.

Crane rotating bed is stopped while switch is held. When

swing holding brake switch is released, circuit to swing brake

release solenoid HS-8 is closed, allowing charge pressure to

hydraulically release spring-applied park brake.

FIGURE 1-10

SWING PUMP

A

B

350 PSI

(24 BAR)

SWING

SUCTION

MANIFOLD

CHARGE

PUMP

LOCK

SWING LEFT

SWING RIGHT

.060

X

X

HS-10

HS-9

HS-8

PILOT CHARGE PRESSURE

FROM REAR DRUM PUMP

BRAKE

SWING

200 PSI

(14 BAR)

B

A

.060

999CSM1-109

3

5

3

6

3

7

3

6

3

9

3

3

3

2

Loading...

Loading...