Manitowoc Published 05-16-17, Control # 233-03 2-9

999 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

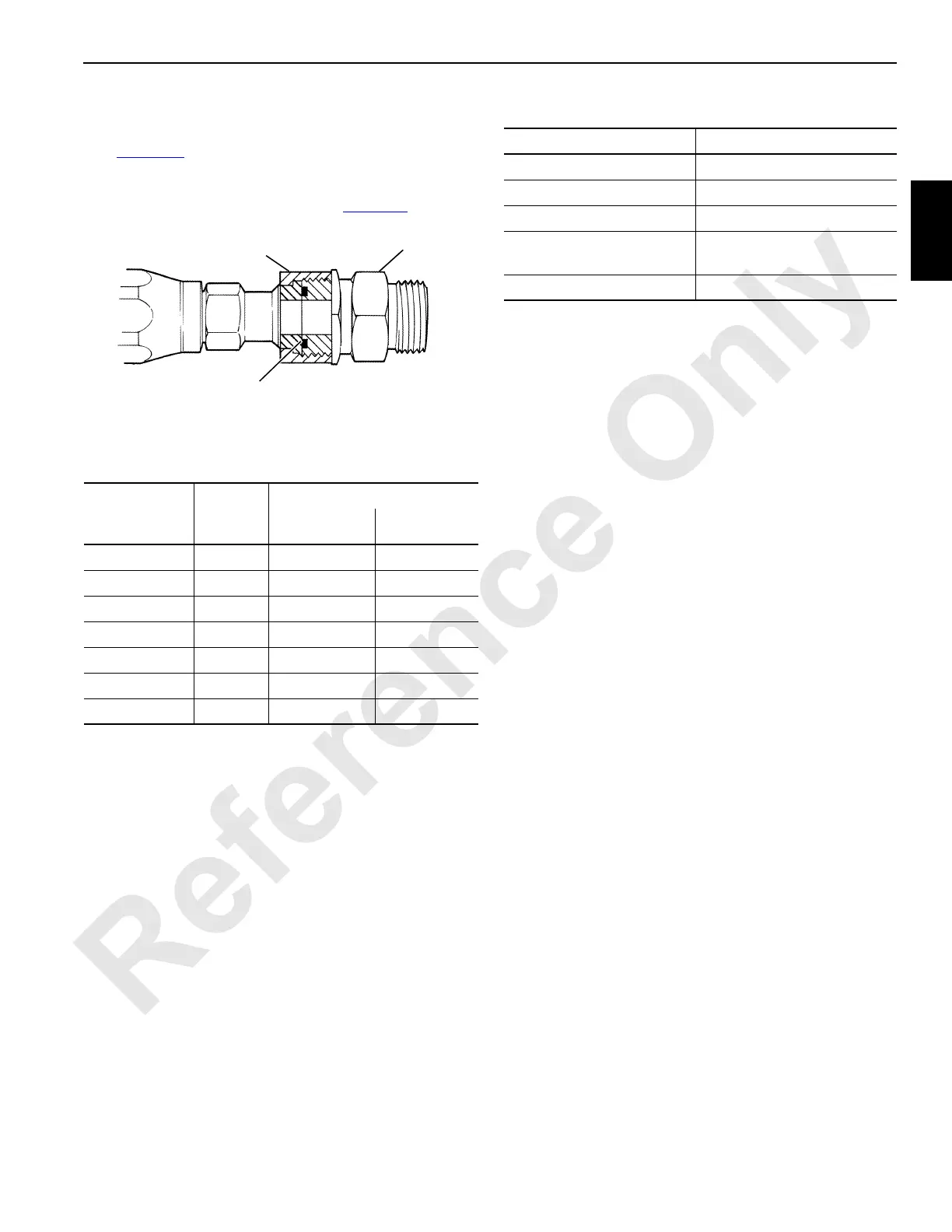

ORS Connection

• Lubricate and install O-ring in adapter groove

(Figure 2-5

).

• Lubricate threads.

• Tighten nut to torque value given in Table 2-4.

.

Table 2-4. ORS Assembly Torque

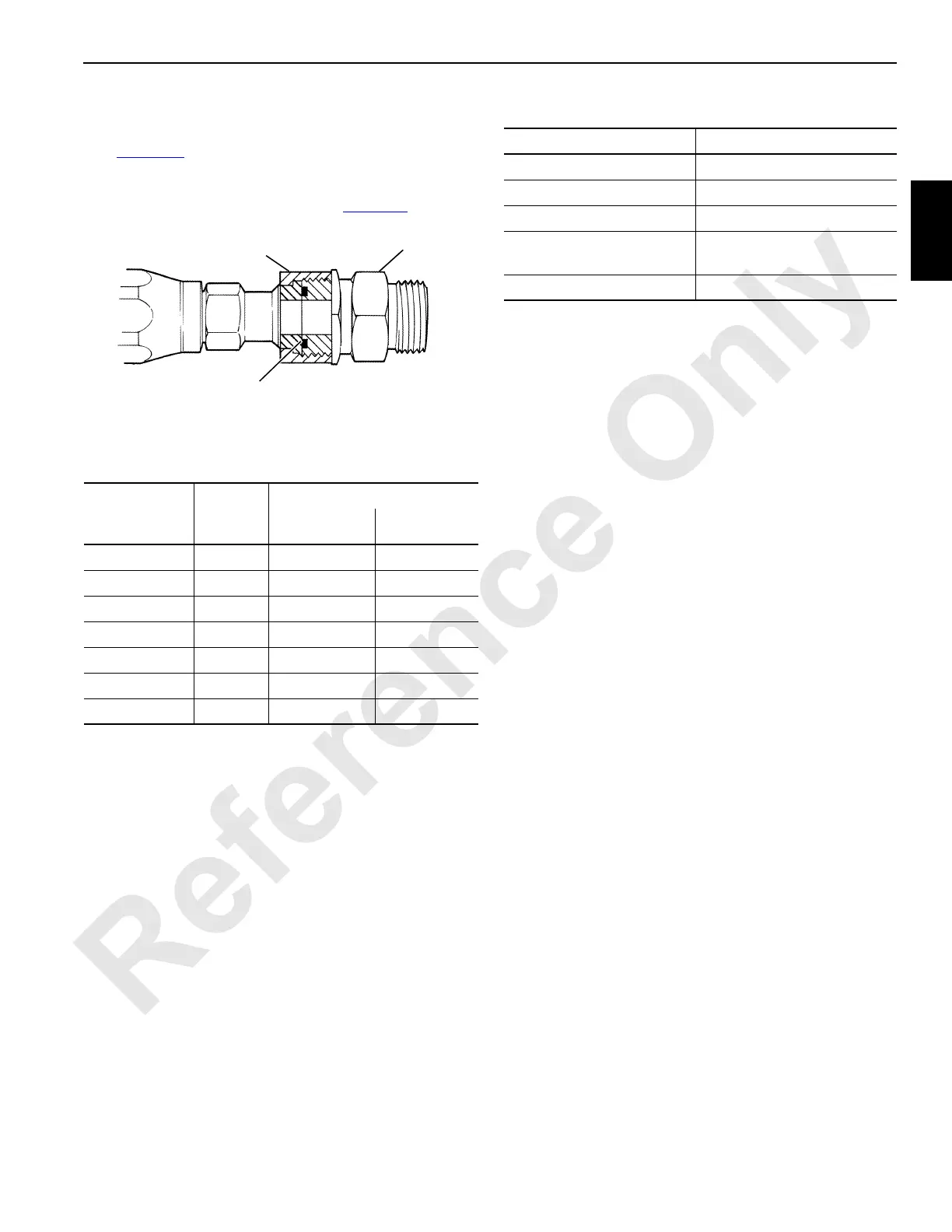

Table 2-5. ORS Leakage

Nut Size

inch across

flats

Fitting

Size

Torque

In-Lb N•m

5/8 -04 120 – 145 14 – 16

13/16 -06 203 – 245 23 – 28

15/16 -08 380 – 470 43 – 53

1-1/8 -10 550 – 680 62 – 77

1-3/8 -12 763 – 945 86 – 107

1-5/8 -16 1110 – 1260 125 – 142

1-7/8 -20 1500 – 1680 170 – 190

Nut

Adapter

O-Ring

FIGURE 2-5

S105

Causes Cures

Nut Loose. Tighten to proper torque.

O-ring cut. Replace.

O-ring wrong size. Replace with proper size.

Sealing surfaces gouged

or scratched.

Repair if possible or replace

damaged parts.

Sealing surfaces dirty. Clean and lubricate.

Loading...

Loading...