TROUBLESHOOTING 999 SERVICE/MAINTENANCE MANUAL

10-58

Published 05-16-17, Control # 233-03

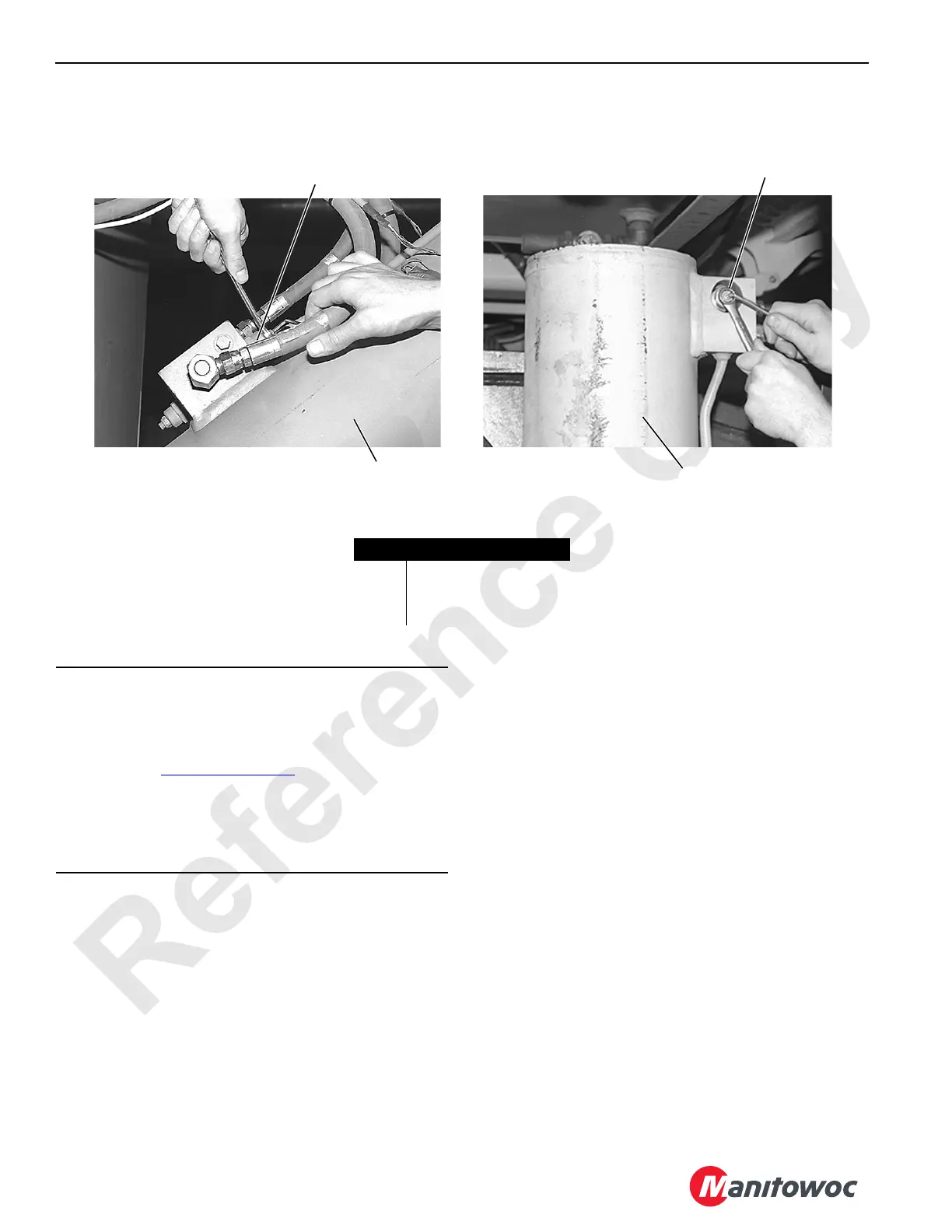

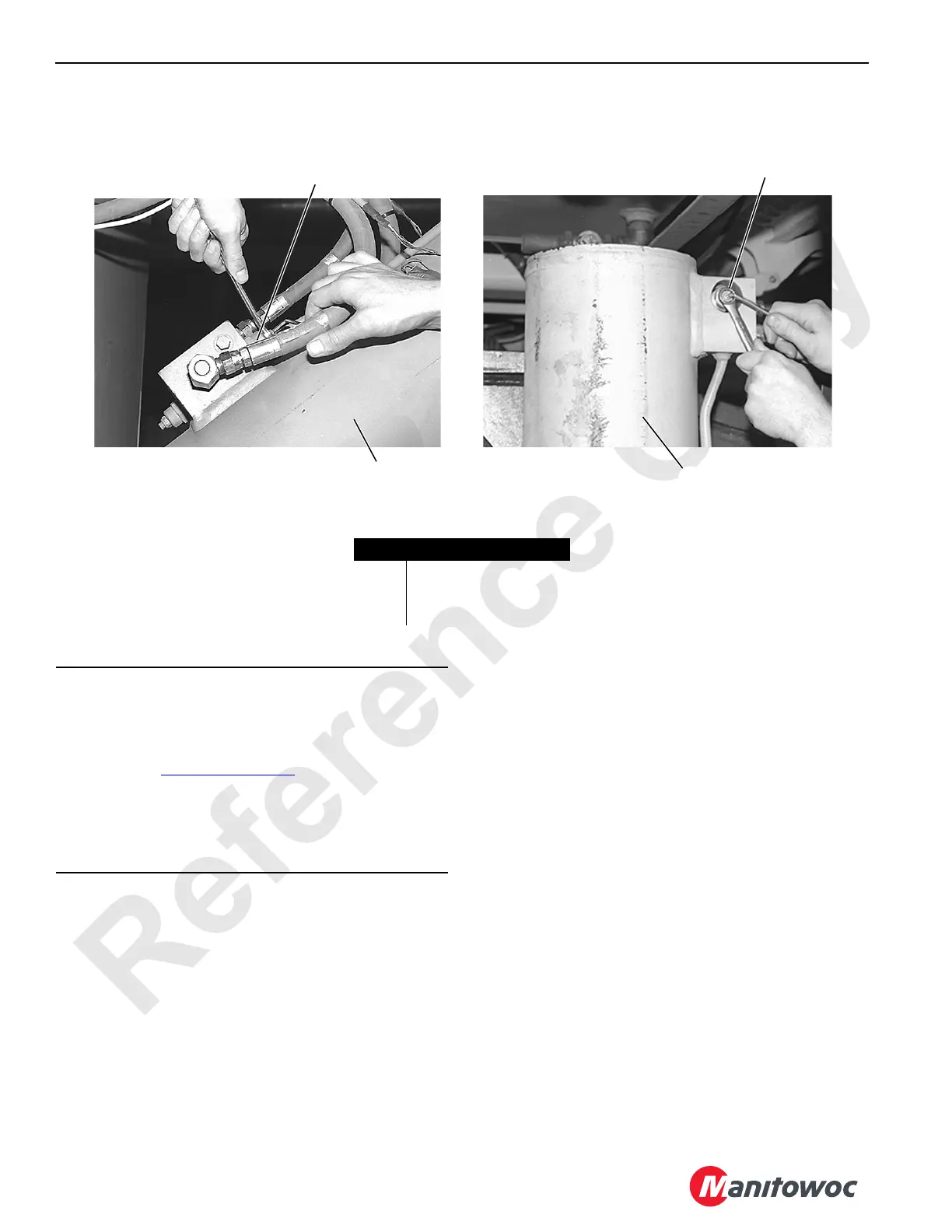

Test 26 – Adjusting the Counterbalance Valves

Each jacking cylinder has a single counterbalance valve at

the piston end of the cylinder. The retract adjusting screw at

the valve provides adjustment for each jacking cylinder load

support. The extend adjusting screw allows cylinders to be

adjusted for uniform operation on level ground.

Counterbalance valves are pre-adjusted at the factory, but

are not calibrated. Adjust counterbalance valves with a

closed-end wrench and hex wrench.

To avoid over-adjusting the cylinders, use a hex wrench as a

guide and never turn a counterbalance valve more than 1/2

turn in either direction.

To adjust a counterbalance valve:

1. Loosen the adjusting lock nut.

2. Rotate counterbalance-adjusting screw 1/2 turn

clockwise (in) to lower holding pressure.

3. Rotate counterbalance adjusting screw 1/2 turn counter-

clockwise (out) to raise holding pressure.

4. While holding counterbalance-adjusting screw with hex

wrench, tighten lock nut.

5. Recheck cylinder(s) for correct load support and uniform

operation.

Item Description

1 Counterbalance Valve

2 Gantry Cylinder

3 Jacking Cylinder

CAUTION

Possible Component Damage!

Special instructions and warnings apply when adjusting

the gantry and boom cylinder counterbalance valves as

specified in Shop Procedures

in Section 2. This

procedure MUST be followed carefully to ensure

adjustments are performed safely. The gantry cylinders

will not extend evenly without counterweights attached to

crane. All gantry cylinder adjustments must be performed

with counterweights installed.

Loading...

Loading...