Manitowoc Published 05-16-17, Control # 233-03 2-13

999 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

a. If 0 appears, all items have passed.

b. If any number other then 0 appears, use Table 2-10.

to determine which items have failed.

NOTE: The cause of a failed calibration or faulty display

pressure reading in the cab may not be the

pressure sender. The cause of the fault could be

trapped air or hydraulic pressure in the system.

Before replacing a pressure sender, do the

following:

• Perform pressure sender calibration steps.

• Attach an accurate hydraulic pressure gauge

to the quick-coupler at the suspect pressure

transducer.

• If pressure appears on the gauge, bleed the

corresponding system so the gauge reads

zero pressure.

• Repeat calibration steps and check pressure

on the display in the cab with the engine

running at idle — the display reading and the

gauge reading should be the same.

• Before replacing a pressure sender, check the

signal voltage at the sender. It should be 1.0

volt against group at 0 psi.

Charge Pressure

The charge pressure screen (Figure 2-10) indicates if each

system’s charge pressure is within 275 – 400 psi (19 – 27

bar), as monitored by the computer.

Charge pressure should be checked at the following

intervals:

• When a new programmable controller is installed

• When a new CPU board is installed

• When a new controller chip is installed

• When a pump is replaced

• When a pump control (EDC or PCP) is replaced

• Every 6 months

To check charge pressure, proceed as follows:

1. Start engine and run at low idle.

2. Access calibration screen (see Accessing Calibration

Screens).

3. Screen indicates state of charge pressure:

a. If 0 appears, charge pressure is okay for all items.

b. If any number other then 0 appears, use Table 2-10.

to determine which items are not within specified

charge pressure.

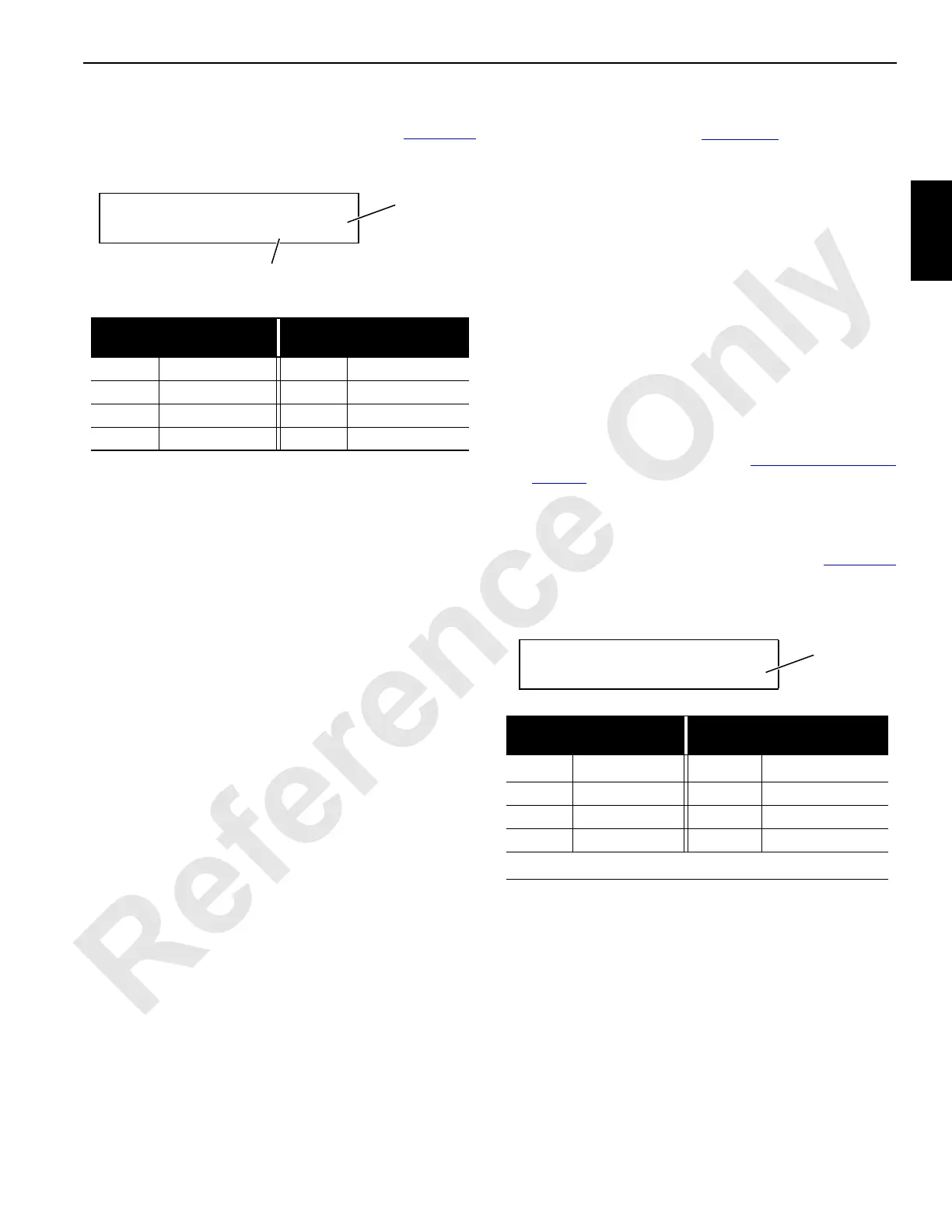

HYD SYSTEM CHECK

* PRES SENDER 0% 15

FIGURE 2-9

Binary

Number

Percent

Complete

Binary

Number

Calibration Item

Binary

Number

Calibration Item

1 Front Drum 16 Swing Left

2 Rear Drum 32 Travel Right

4 Boom Hoist 64 Travel Left

8 Swing Right 128 Accessory System

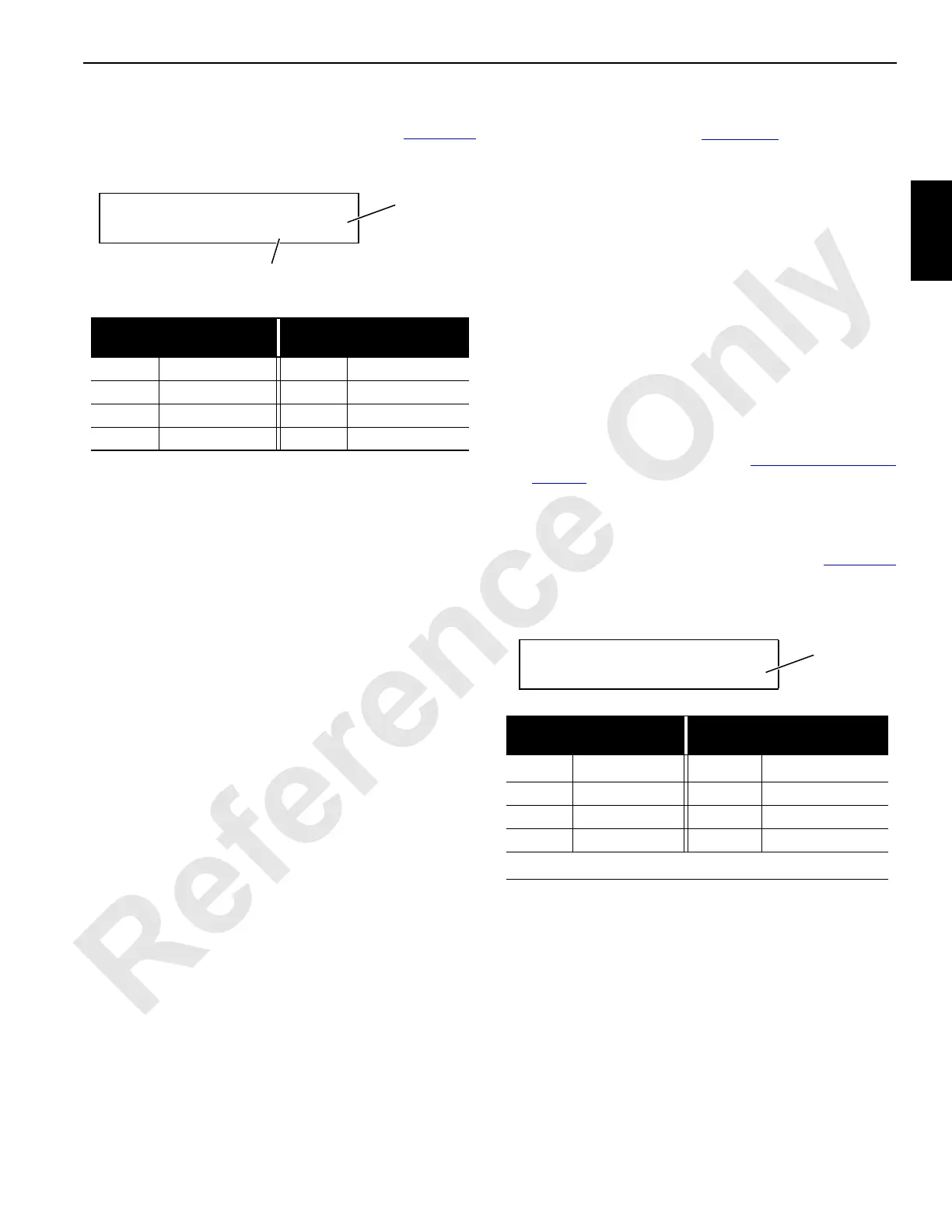

HYD SYSTEM CHECK

* CHARGE PRES 15

FIGURE 2-10

Binary

Number

Binary

Number

Calibration Item

Binary

Number

Calibration Item

1 Front Drum 16

Swing Left

1

2 Rear Drum 32 Travel Right

4 Boom Hoist 64 Travel Left

8 Swing Right 128 Accessory System

1

Same Pump as Swing Right

Loading...

Loading...