INTRODUCTION 999 SERVICE/MAINTENANCE MANUAL

1-46

Published 05-16-17, Control # 233-03

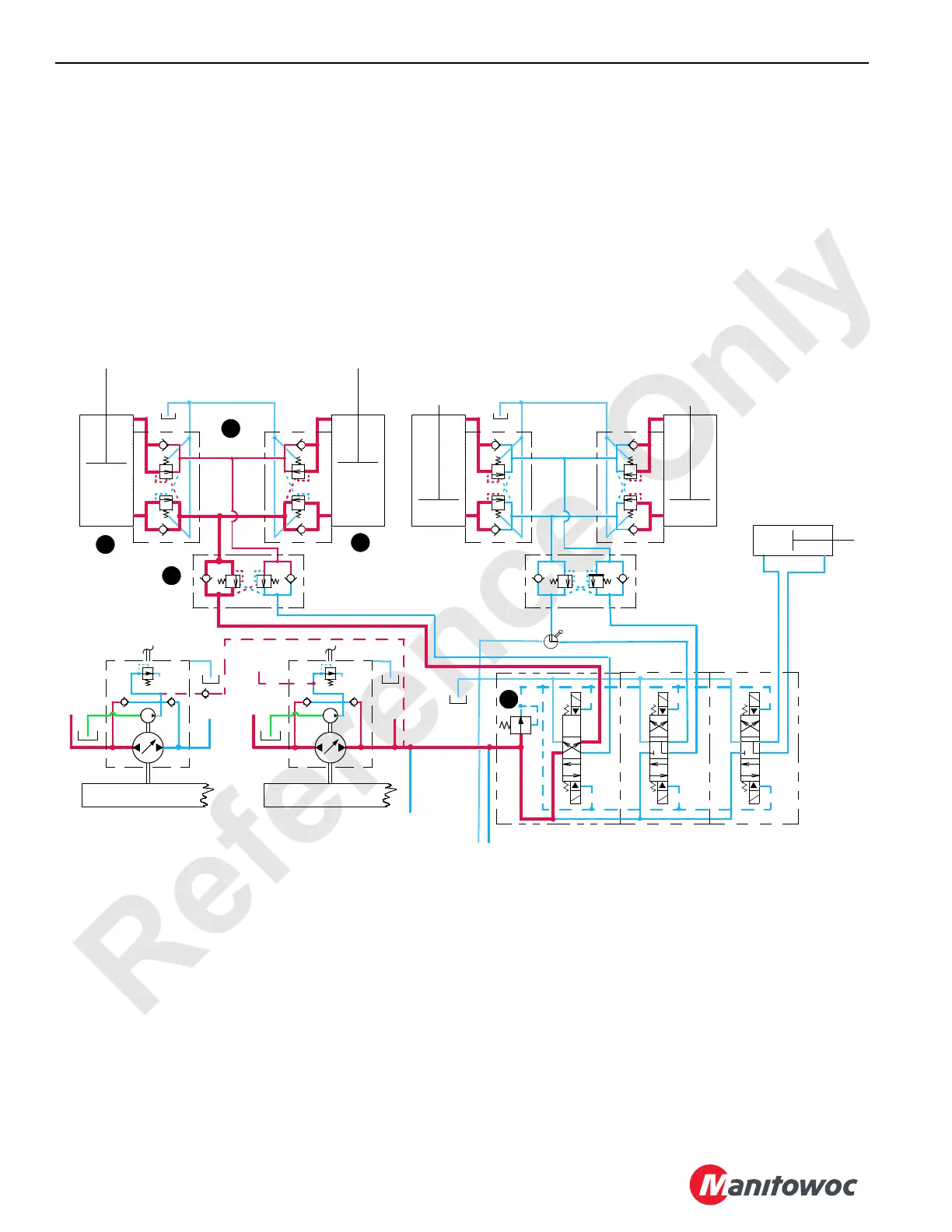

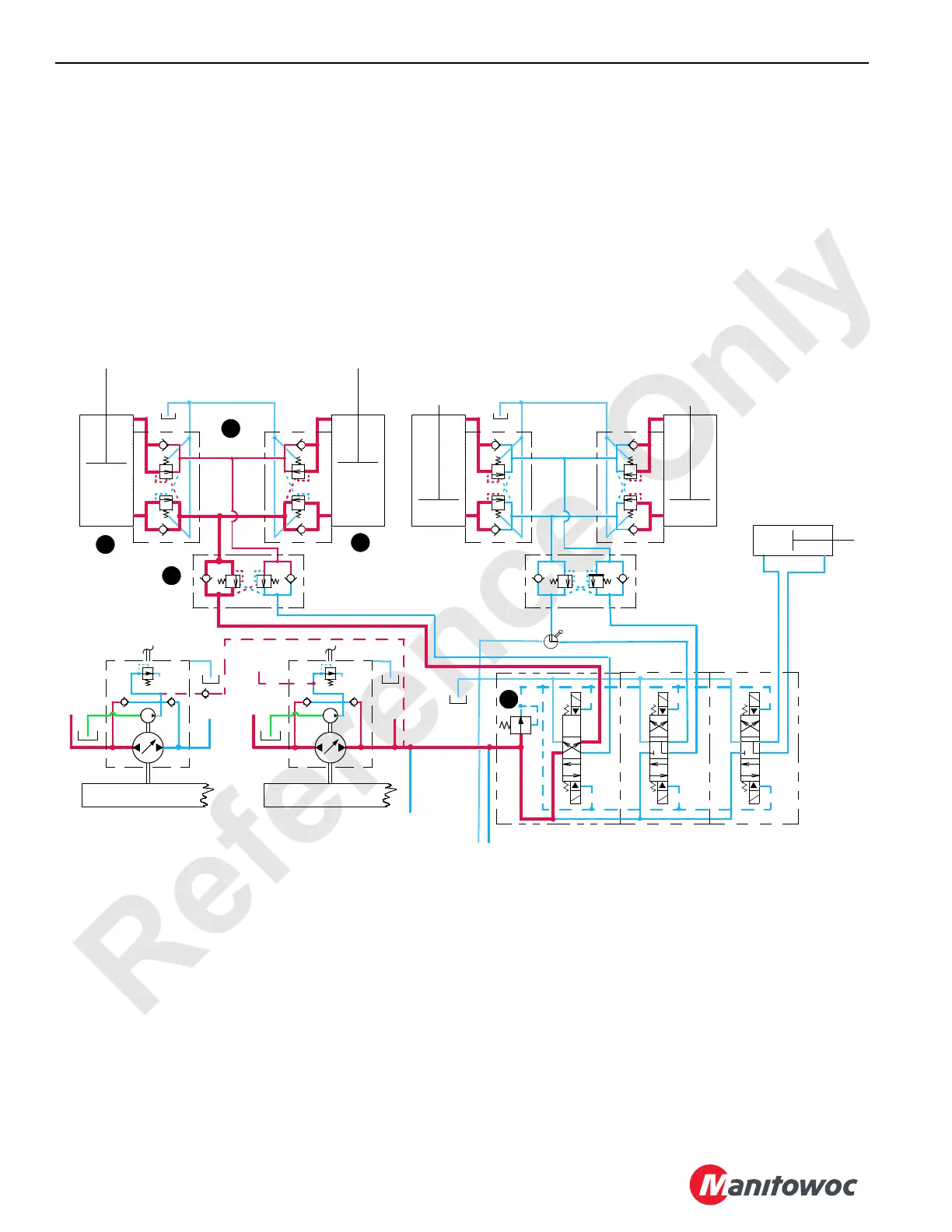

The PC sends a negative output voltage to rear drum pump

EDC (13) that tilts rear drum pump swashplate to stroke

pump in the low-pressure side direction. Low-pressure side

hydraulic fluid flows to gantry extend cylinder solenoid HS-3

of upperworks accessory valve and through free flow check

valve sections on side “A” of load equalizing valve (8). From

the equalizing valve, fluid enters counterbalance valves (7)

and piston end of gantry cylinders (6), extending cylinder

rods to raise the gantry. As gantry raises, boom hoist drum

pays out wire rope.

The PC monitors rear drum pressure senders to control

gantry cylinder raising speed rate.

The free-flow check valve sections on side “B” of

counterbalance valves block fluid exhausting from rod end of

gantry cylinders. Fluid passes through flow restrain sections

of counterbalance valve that have a relief setting of 3,500 psi

(240 bar). Counterbalance valves act as a deceleration

control and operate with a 5:1 pilot ratio of the relief valve

pressure, permitting the valves to open when pressure in the

piston end of cylinders is approximately 700 psi (48 bar).

Exhaust fluid from side “B” of both counterbalance valves

combines and fluid passes through non-restrictive portion of

load equalizing valve before entering accessory system

valve. Hydraulic fluid exits the accessory system valve and

returns to tank.

The free-flow check valve sections on side “B” of load

equalizing valve block the flow. Hydraulic fluid then passes

through flow restrain section of valve that is preset at 4,000

psi (275 bar).

Load equalizing valve operates with a 1.5:1 pilot ratio of the

relief valve pressure, permitting valve to open when

hydraulic pressure from the setup pump (rear drum) on side

“A” of the valve is approximately 2,670 psi (185 bar).

Restraining section on side “B” of load equalizing valve

opens, controlling fluid out of both cylinders and ensuring

cylinder actuation is balanced.

When gantry is fully raised, gantry up limit switch closes

sending an input signal to PC. The PC sends an output

signal to de-stroke rear drum pump. The PC also sends an

output signal to shift gantry extend cylinder solenoid HS-3

back to center position. The PC goes to next sequence step

of raising mast.

FIGURE 1-33

HIGH

UPPERWORKS ACCESSORY MANIFOLD

REAR DRUM

PUMP DRIVE GEARBOX

HS-4

A

A

A

BB

B

BOOM HINGE

PIN

CYLINDER

LOAD EQUALIZING

VALVE

4,000 PSI (275 BAR)

MAST RAISING CYLINDERS

3,500 PSI (240 BAR)

LOW

HS-3

HS-2

HS-1

HS-6

HS-5

3

7

A

A

A

BB

B

LOAD EQUALIZING

VALVE

4,000 PSI (275 BAR)

GANTRY CYLINDERS

3,500 PSI (240 BAR)

HIGH

FRONT DRUM

PUMP DRIVE GEARBOX

LOW

LOW PRESSURE

ACCESSORIES

3

8

3

6

TO LOWERWORKS

ACCESSORY MANIFOLD

3

6

999CSM1-132

TO REAR HOIST MOTOR

LOOP FLUSHUNG VALVE

3

14

Loading...

Loading...