8

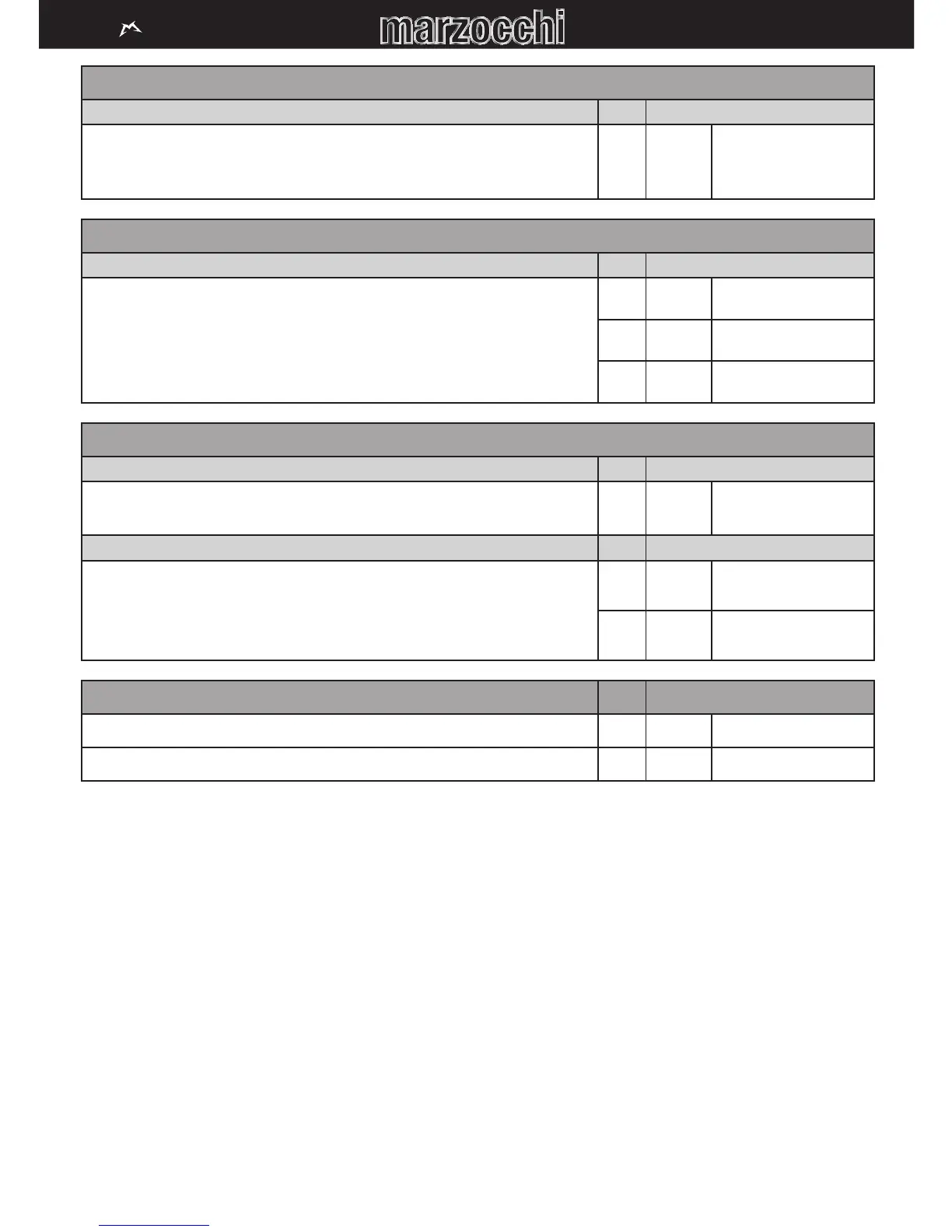

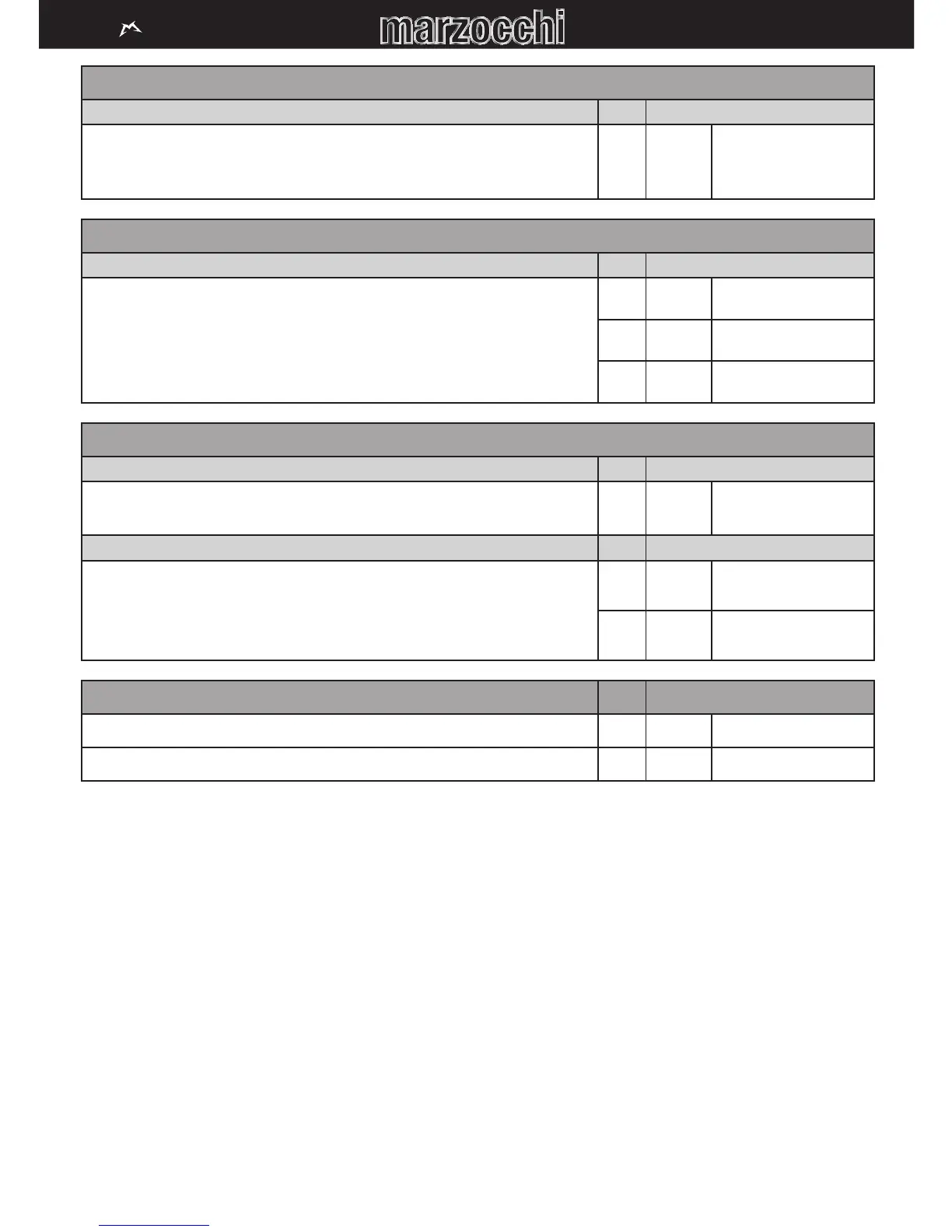

OPEN BATH

RV Pos.

The RV (Rebound Valve) pumping element is the evolution of the well-proven SSVF

Open Bath system. This system controls the rebound speed. If you correctly adjust the

red-coloured knob on the lower part of the fork leg, you can keep the wheel on contact

with the soil in all riding conditions.

>

red Rebound

SEALED

TST MICRO (Terrain Selection Technology With Micro Adjuster) Pos.

TST Micro is the greatest evolution of TST closed cartridge hydraulic systems. The red

knob installed in the lower part of the fork leg adjusts the rebound. The black-coloured top

knob sets Micro System to adjust the compression. The Micro adjustment (golden knob

on the top of the fork leg) sets the operating threshold of compression by adapting the

behaviour of the suspension system to the type of terrain. Lockout is activated by turning

the golden knob completely in the closed position, then shifting the red lever. In some

models, the TST system can be operated through the remote control on the handlebar.

>>

gold Compression/ Blow Off

>

black Lockout

>

red Rebound

AIR SYSTEMS

AER Pos.

By means of a single Schrader air valve in the upper or lower part of the fork leg,

depending on the model, the AER pneumatic cartridge allows a perfect and simple

adjustment of the pressure in the positive air chamber.

>

Ti grey Air spring

STA (Switch-TA) Pos.

The STA cartridge has the functionalities of the AER system. It allows easy setting by

means of a single air valve installed in the lower part of the fork leg. In addition, the

STA cartridge, by means of the rotation of the Silver-coloured STA knob installed on

the top of the fork leg, allows adjustment of the fork height and travel without affecting

the damping system.

>

Smoke

grey

Travel adjust

>

Ti grey Air spring

SPRING PRELOAD Pos.

Coil preload with mechanical adjuster

>

Ti grey Spring preload

Coil preload with air

>

Ti grey Spring preload

Table 2 - Technology and Adjustment - Detail

2.3 Lubrication and cooling

The forks can use different lubrication and cooling technologies.

In Open Bath systems, the oil inside the fork leg, besides being a

crucial element for the hydraulic operation, accomplishes all cooling

and lubrication needs for the internal sliding parts. In addition, if

the oil volume is varied within the recommended ranges, it will

be an additional setting element, thus allowing the modifi cation

of suspension system’s progressivity. Compared to the systems

equipped with sealed cartridges, the Open Bath system allows

increased lubrication for the operation of the sliding parts.

The Open Bath system assures an excellent lubrication from the very fi rst

“bottoming” of the fork, as well as in all use and weather conditions.

In the systems equipped with sealed cartridge, special grease or oil

is used for the lubrication of the internal sliding parts. The aforesaid

lubricant does not work as additional setting element; therefore, the

pre-established levels must be carefully observed.

The best lubrication of the internal parts is achieved during use,

when the stress and the bottoming of the fork allow the oil to lift

due to “chattering” from the bottom of the fork leg until reaching

and lubricating the bushings.

2.4 Sliding bushing and oil seals

The guide of the stanchion tubes inside the sliders is formed by

two bushings utilizing an advanced Tefl on® facing, with very low

static friction.

In 44, 350, 55, 380, 888, 320, Corsa and Marathon models the

notorious smoothness of Bomber models has been increased

further, thanks to the use of these newly designed bushings

and seals offering a coeffi cient of friction that is 30% lower than

previously obtainable. These new bushings and seals have proven

to give better consistent performance over time. This allows the

optimum combination between the fork legs and the sliders. The

new bushings have slots that help the oil to go up and improve

the lubrication, thus offering an incomparable smoothness. At the

top end of the monolite, there is a sealing group that prevents oil

leakages, as well as the access of contaminating agents into the

lubricant and into the hydraulic cartridges.

Loading...

Loading...