26

2. Raise the blade so that it is about 1/8” (3.2 mm) higher than the top of the

workpiece.

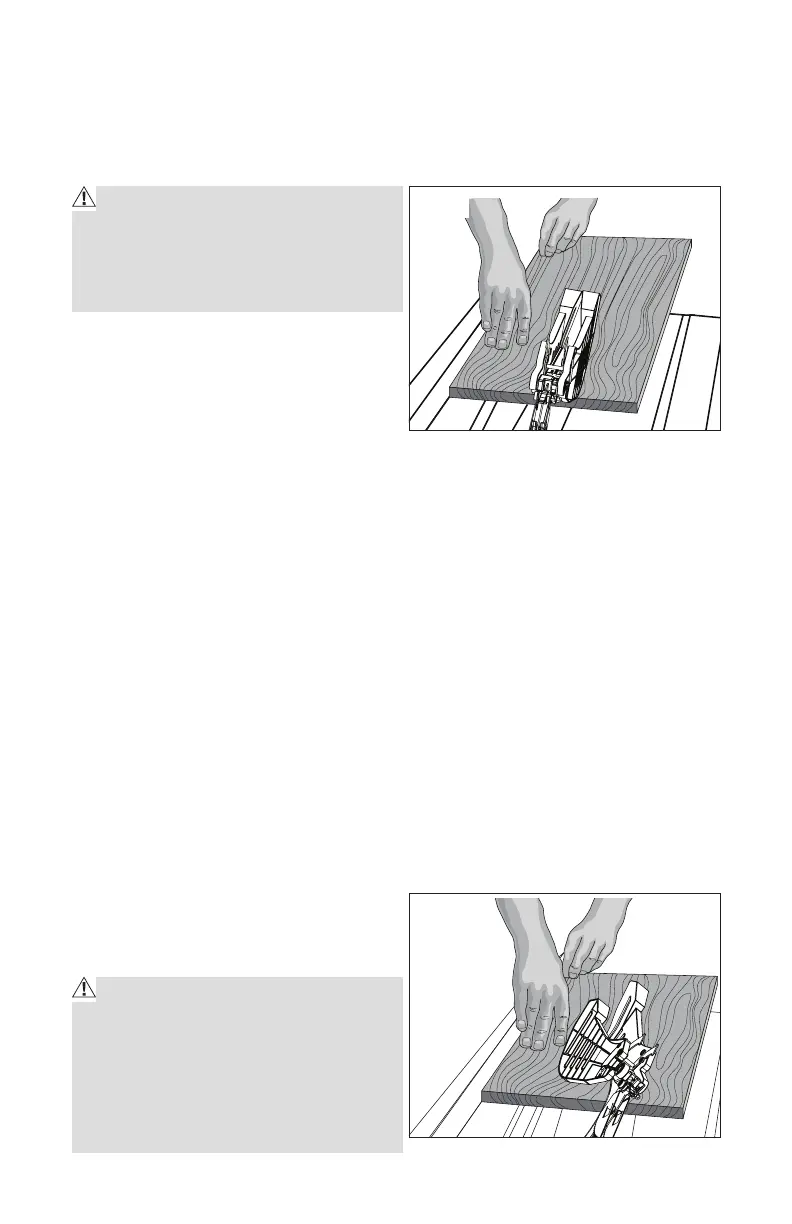

3. Hold the workpiece flat on the table and against the fence. Keep the

workpiece about 1” (25.4 mm) away from the blade.

CAUTION! The workpiece must have

a straight edge against the fence,

and

must not be warped, twisted or bowed.

Keep both hands away from the blade

and away from the path of the blade.

4. Turn the saw on, and allow the

blade to come up to speed. Both

hands can be used in starting the

cut. When there is approximately

12” (305 mm) left to be ripped,

use only one hand, with your thumb pushing the material, your index and

second fingers holding the material down, and your other fingers hooked

over the fence. Always keep your thumb alongside your first two fingers

and near the fence.

5. Keeping the workpiece against the table and the fence, slowly feed the

workpiece all the way through the saw blade toward the rear. Continue

pushing the workpiece until it is clear of the guard and it falls off the rear

of the table. Do not overload the motor.

6. NEVER try to pull the workpiece back with the blade turning. Turn the

switch off, allow the blade to stop, raise the anti-kickback pawls on each

side of the spreader, if necessary, and slide the workpiece out.

7. When sawing a long piece of material or a panel, always use a work

support. A sawhorse, rollers or out-feed assembly provides adequate

support for this purpose. The work support must be at the same height as

the saw table.

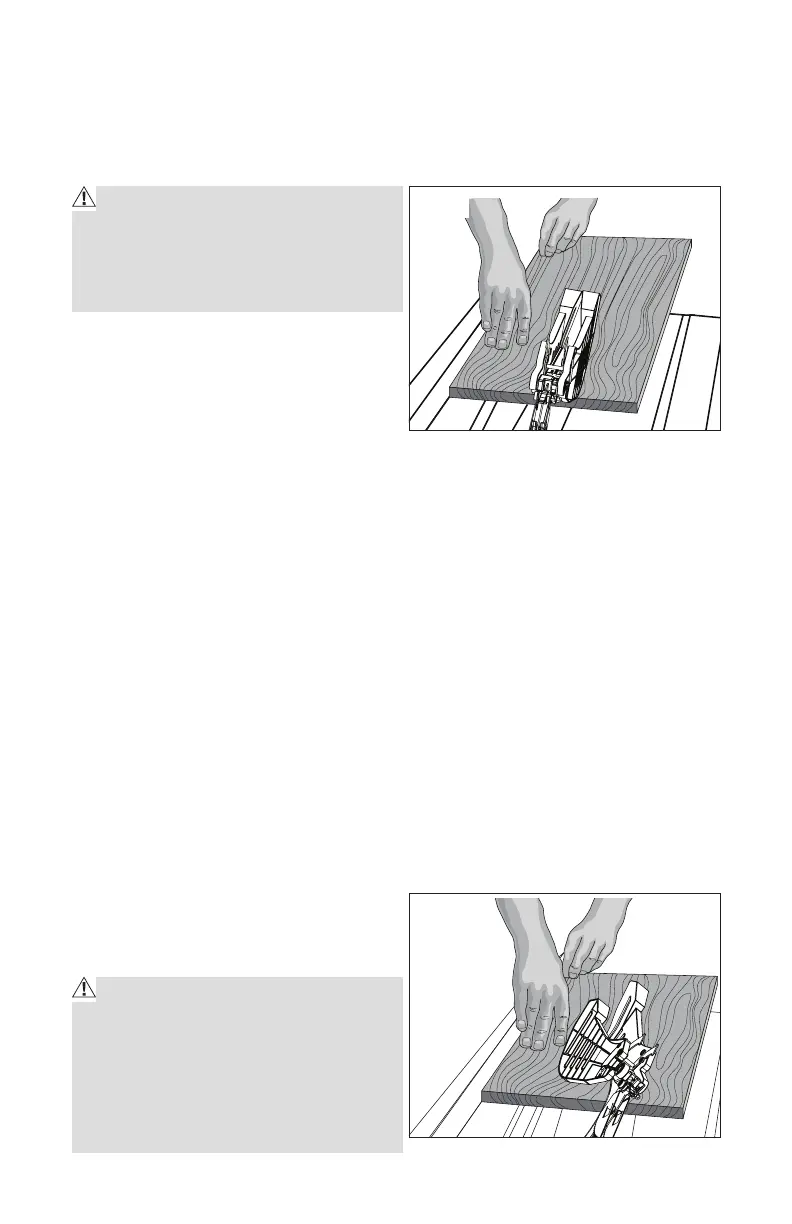

BEVEL RIPPING (Refer to Fig. 24)

This operation is the same as ripping,

except that the bevel angle is set to an

angle other than 0°.

WARNING! Before connecting the

table saw to the power source or

oper-

ating the saw, always inspect the guard

and splitter for proper alignment and

clearance from the saw blade. Check

the alignment after each change of bevel

angle.

Fig. 23

Fig. 24

Loading...

Loading...