19

TM

GLOSSARY OF TERMS

TM

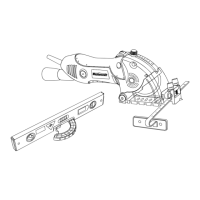

POSITIVE STOP LOCKING LEVER – Locks the mitre saw at a preset positive stop for

the desired mitre angle.

SWITCH HANDLE – The switch handle contains the trigger switch and safety lock-off

button. The blade is lowered into the workpiece by pushing down on the handle. The

saw will return to its upright position when the handle is released.

WARNING LABELS – Read and understand for your own safety. Make sure all labels are

present on machine and legible.

WRENCH STORAGE – Convenient storage to prevent misplacing the blade wrench.

WOODWORKING TERMS

ARBOUR – The shaft on which a blade is mounted.

BEVEL CUT – An angle cut made through the face of the workpiece.

COMPOUND CUT – An angled cut to both the edge and face of a board, most common

use is with crown moulding.

CROSSCUT – A cut that runs across the board perpendicular to the grain.

FREEHAND – Performing a cut without using a fence (guide), hold-down or other

proper device to prevent the workpiece from twisting during the cutting operation.

HEEL – Misalignment of the blade.

KERF – The width of a saw cut, determined by the thickness and set of the blade.

KICKBACK – Sudden and unintended movement of the tool or workpiece. It is typically

caused by binding or pinching of the workpiece

MITRE CUT – A mitre is a type of joint where the two parts to be joined are cut at an

angle, and the finished joint typically forms a 90° angle. Also commonly spelled

“miter.”

REVOLUTIONS PER MINUTE (RPM) – The number of turns completed by a spinning

object in one minute.

SAW BLADE PATH – The area of the workpiece or table top directly in line with the

travel of the blade or the part of the workpiece that will be cut.

SET – The distance between two saw blade tips, bent outward in opposite directions

to each other. The further apart the tips are, the greater the set.

THIN-KERF BLADE – Thinner than normal blades, remove less material, smaller kerfs

(between 0.065” and 0.070”). Blade thinness may also increase the heat generated

while cutting.

WORKPIECE – The wood being cut. The surfaces of a workpiece are commonly

referred to as faces, ends and edges.

Loading...

Loading...