35

TM

ADJUSTMENTS

LASER GUIDE ADJUSTMENT

(Fig. 28, 29, 30, 31)

NOTE: All the adjustments for the operation

of this machine have been completed at the

factory. Due to normal wear and use, some

occasional readjustments may be necessary.

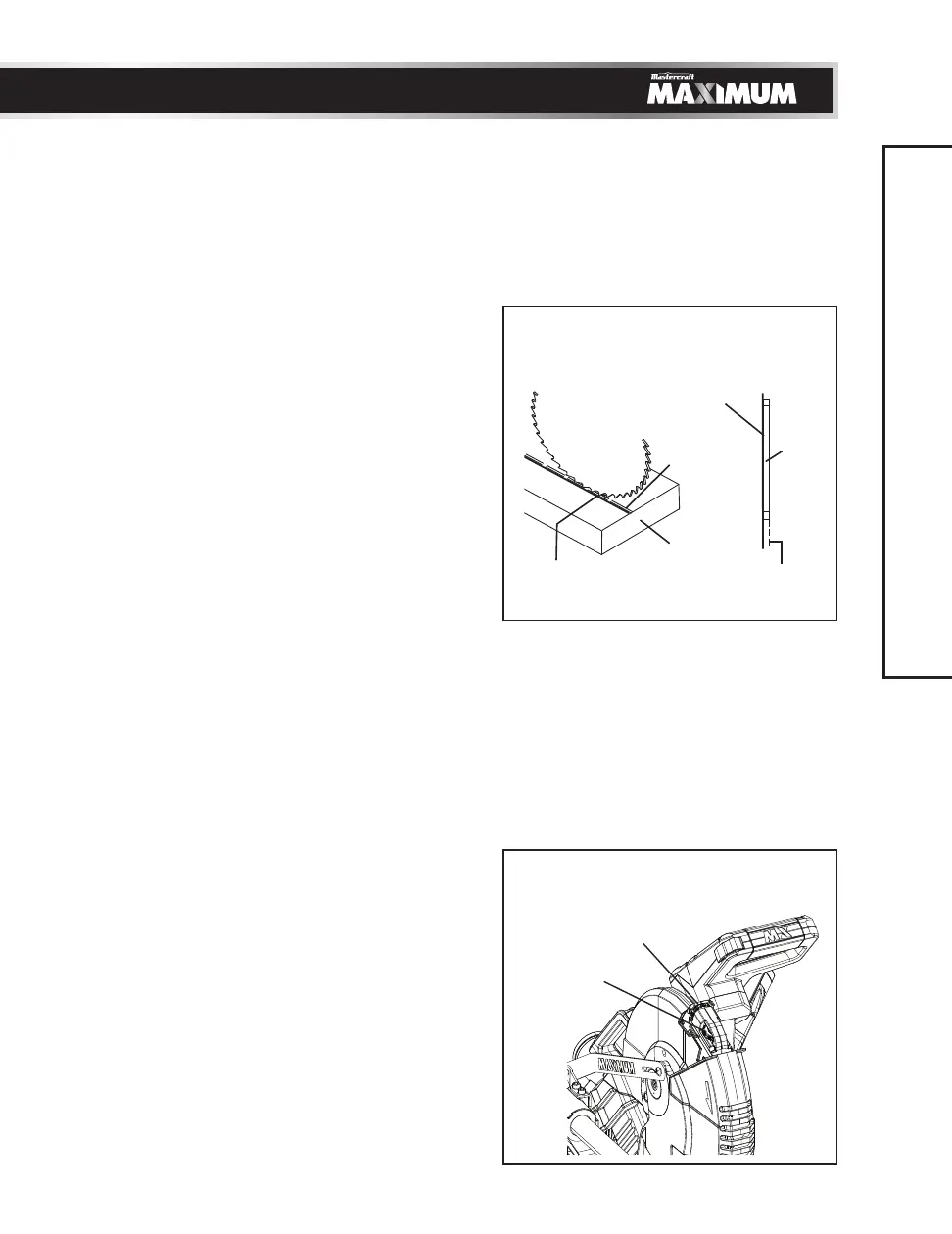

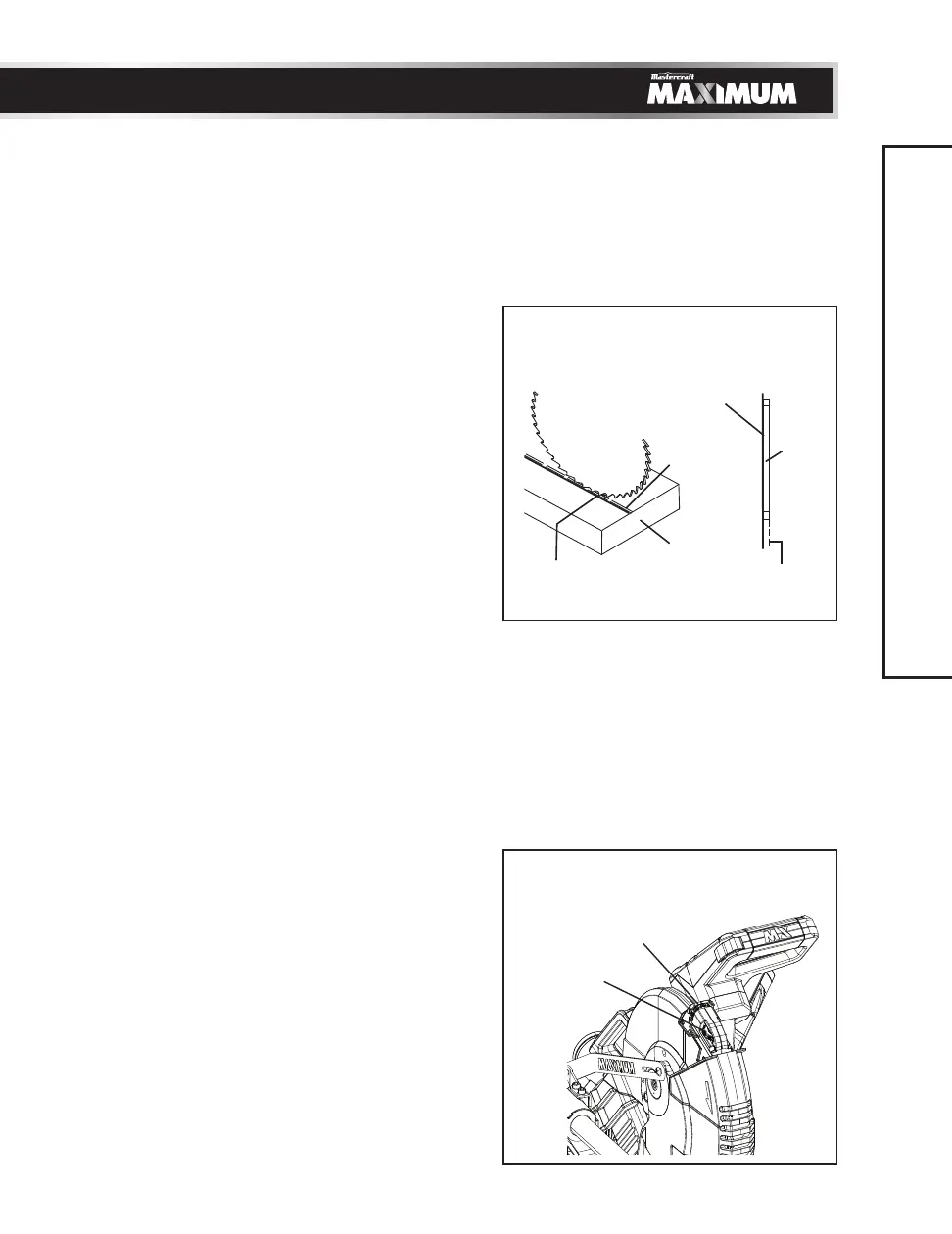

A. Checking Laser Beam Alignment (Fig. 28)

• Set the saw to a 0° mitre and 0° bevel

setting.

• Take a board and using a straight edge (not

included), mark a 90° line on the top and

front of the board. This line will serve as a

“pattern line” for all laser beam alignments.

Place the board on the saw table.

• Carefully lower the cutting head down to

align the saw blade with the pattern line.

Position the saw blade to the left, centre or

right side of the “pattern line” depending

on your preference for the laser beam

location.

• With the saw plugged in, turn on the laser

guide. Your saw has been preset with the

laser beam to the left side of the blade.

• Looking at the front of the board, if the

laser beam is not parallel to the “pattern

line” please follow the instructions listed

below under Procedure A.

• Looking at the top of the board, if the laser

beam is not parallel to the “pattern line”

please follow the instructions listed below

under Procedure B.

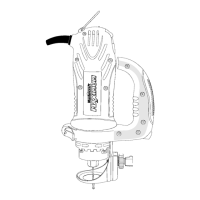

B. Adjusting the Position of the Laser Beam

Procedure A (Fig. 29, 30)

• Slightly turn the laser vertical adjustment

knob (1) to adjust the vertical angle of the

laser beam on the front of the board. When

the laser beam angles from left to right,

turn the laser vertical adjustment knob (1)

clockwise; if the laser beam angles right to

left, turn the laser vertical adjustment

knob (1) counter-clockwise until the laser

beam is parallel with the vertical

“pattern line.”

Fig. 29

Fig. 28

1

2

Laser beam

Cutting line

TOP VIEW

Blade

Laser beam

Workpiece

Cutting

line

Loading...

Loading...