Why hydraulics are under pressure when wrapper is idle on McHale W2020 Farm Equipment?

- CcsullivanAug 15, 2025

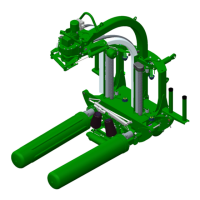

If the hydraulics are under pressure when your McHale Farm Equipment wrapper is idle, the valve may be set to closed-centre on an open-centre system. Change the valve setting.