McHale W2020 Round Bale Wrapper

70

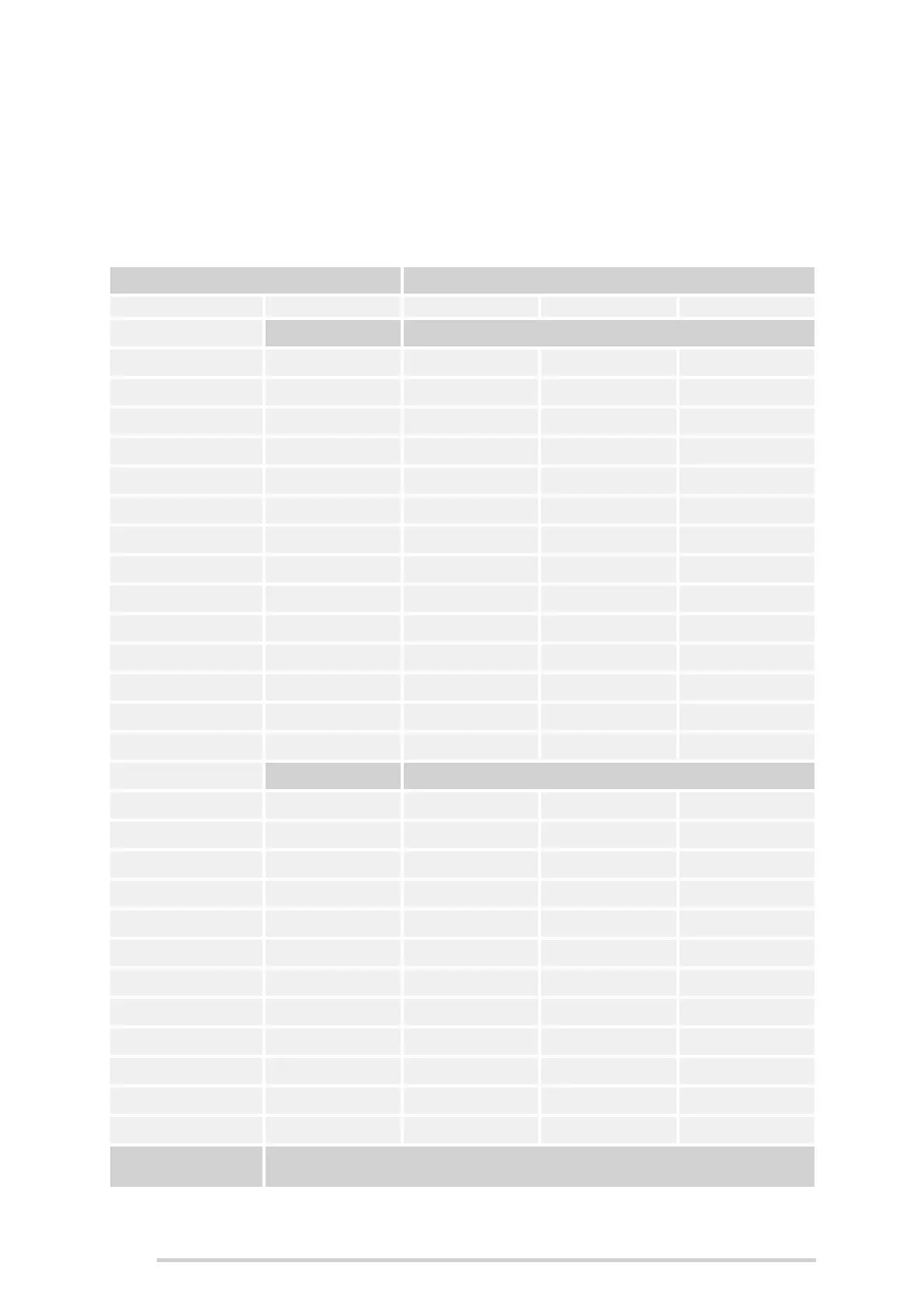

10.5 Tightening torque values

It is important that the correct torques for fasteners are adhered to. Below are tables of

recommended torques for these. These are to be used unless torques are otherwise

specified. These values are for general use only. Check tightness of all fasteners

periodically. Torque values are in Nm (Newton metres).

Nuts and bolts Black, Phosphated or Galvanized

Grade marking 8.8 10.9 12.9

Dimensions Metric standard thread

Hex. bolts M4 2.7 3.8 4.6

DIN 931 M5 5.5 8 9.5

DIN 933 M6 10 14 16

M8 23 33 40

Socket head M10 45 63 75

Cap screws M12 78 110 130

DIN 912 M14 122 175 210

M16 195 270 325

Hex. nuts M18 260 370 440

DIN 934 M20 370 525 630

M22 510 720 870

M24 640 900 1,080

M27 980 1,400 1,650

M30 1,260 1,800 2,160

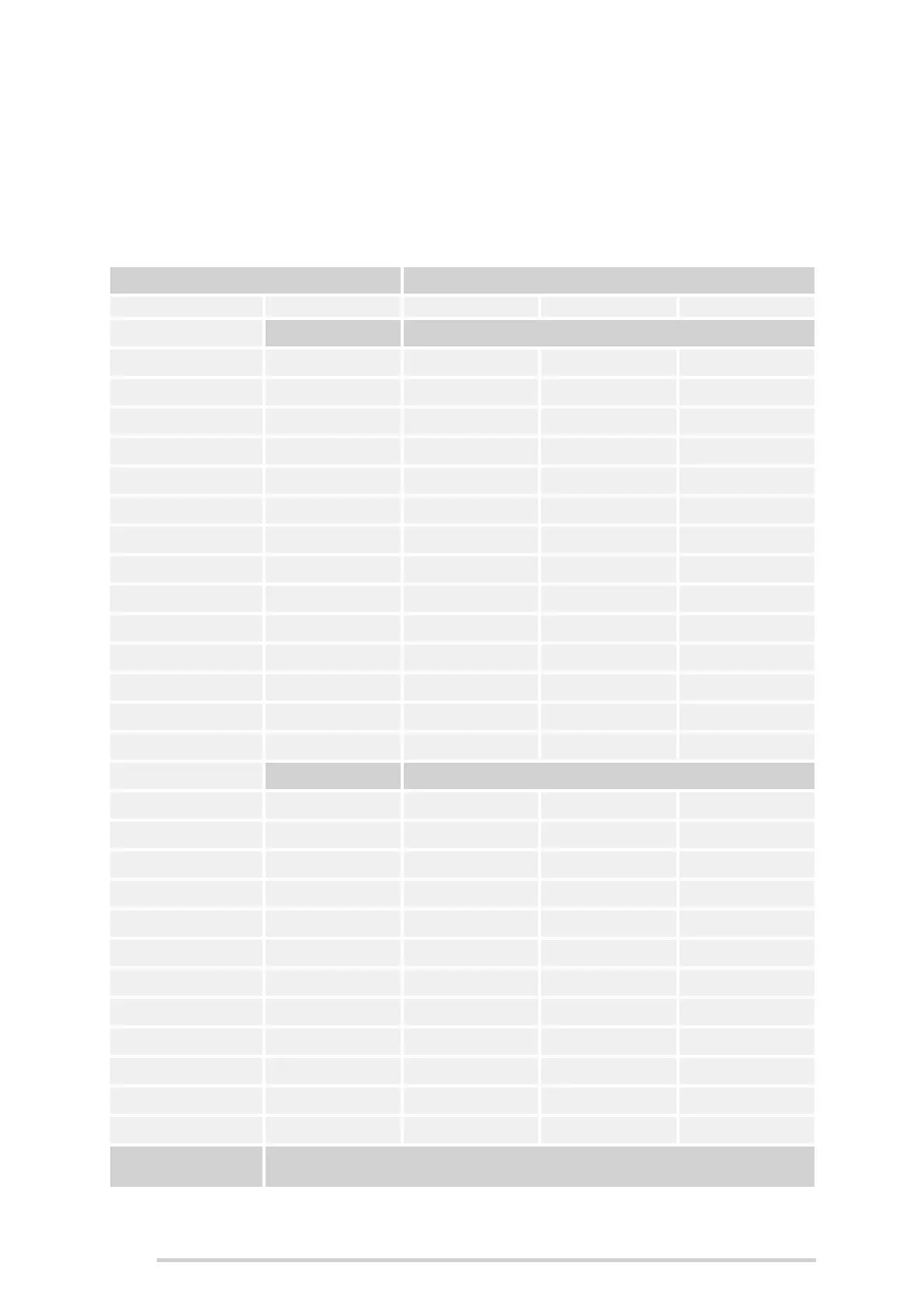

Dimensions Metric fine thread

Hex. bolts M8 x 1 25 35 42

DIN 960 M10 x 1.25 48 67 80

DIN 961 M12 x 1.25 88 125 150

M12 x 1.5 82 113 140

Hex. nuts M14 x 1.5 135 190 225

DIN 934 M16 x 1.5 210 290 345

M18 x 1.5 300 415 505

M20 x 1.5 415 585 700

M22 x 1.5 560 785 945

M24 x 2 720 1,000 1,200

M27 x 2 1,050 1,500 1,800

M30 x 2 1,450 2,050 2,500

NOTE:

For nuts and bolts from different materials and/or surface finishes a

torque value must be used that is lower than the value stated above.

Loading...

Loading...