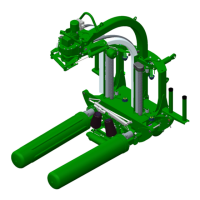

Why McHale HS2000 Farm Equipment side lift arm does not go out or in?

- SscottlanceAug 3, 2025

The side lift arm may not extend or retract due to several reasons. First, check that the oil is turned on and the quick release coupling is properly connected, ensuring an oil feed of 35l/min. Also, verify that the ‘tank return’ line is correctly connected “to tank” and inspect the quick release coupling. Refer to your tractor manual for hydraulic connection details. An electrical fault, such as loose connections or a weak battery, could also be the cause; ensure a 13V supply is available and all electrical connections are secure. Finally, make sure to press the side lift arm button promptly, as the diverter operation cancels after two seconds.