McHale HS2000 Round Bale Wrapper

62

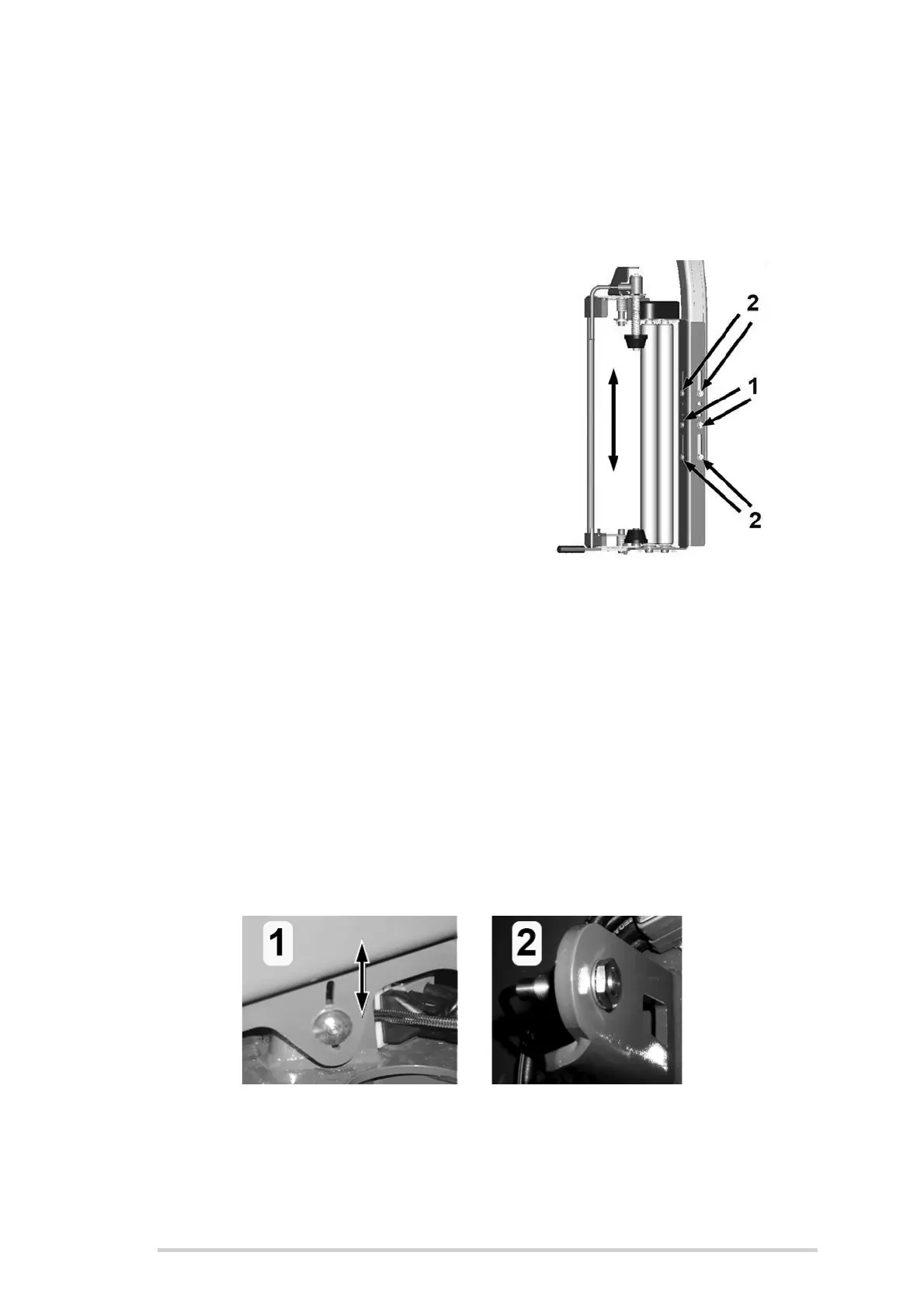

10.3 Dispenser height

The plastic film needs to be applied around the centre of the bale to ensure optimum

coverage. To achieve this, the dispenser may need to be adjusted up or down as

necessary. Do not adjust too low as the dispenser may touch the cut and hold.

The dispenser height may be adjusted as follows:

1. Remove the 2x centre bolts and washers.

2. Open the 2x top bolts and 2x bottom bolts

back a few threads. Do not remove these

bolts as they support the weight of the

dispenser unit.

3. There are three height positions for the

dispenser unit. Move the dispenser up or

down as required. Insert the centre bolt

when the desired height has been selected.

4. Tighten all bolts fully.

5. Rotate dispensers slowly to ensure that

they do not touch any other part of the

machine.

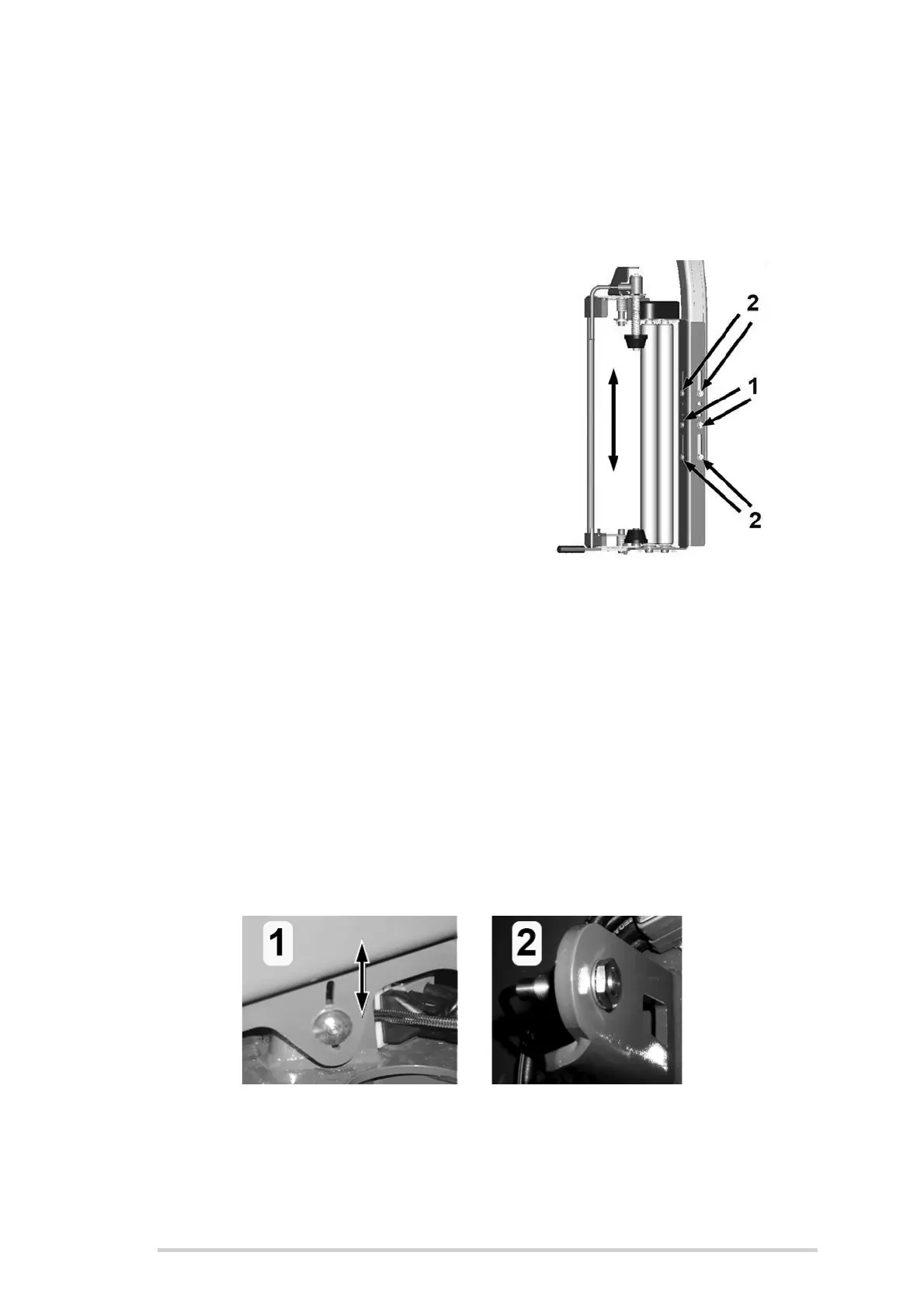

10.4 Table levelling adjustment

After a period of time it may become necessary to readjust the level of the table. The

table should be horizontal when in wrapping mode. If the table is not operating properly

it is very possible that it is due to one of the following: broken/missing magnet,

damaged sensor or loose sensor connection.

1. Run the machine and if the table is off level within ±20 mm then adjust the table

magnet accordingly as shown. If the front is lower than the rear, then move the

magnet slightly downwards. The opposite also applies; although a central

position of the slot generally works well for table levelling.

2. The sensor must be positioned facing the magnet. The end of the sensor

should be flush with the nut.

Loading...

Loading...