McHale HS2000 Round Bale Wrapper

61

10

Field Operation & Wrapper Adjustments

From time to time it may become necessary to carry out adjustments to the machine,

whether to improve machine performance or allow for general wear and tear. Such

adjustments are part of the machine design. The following chapter gives details of how

to go through the various adjustments. Some of these are field adjustments while

others will be performed during machine maintenance or initial set-up. All of these

adjustments should be checked thoroughly before the machine goes to work for the

first time.The wrapper should be parallel to the ground when working.

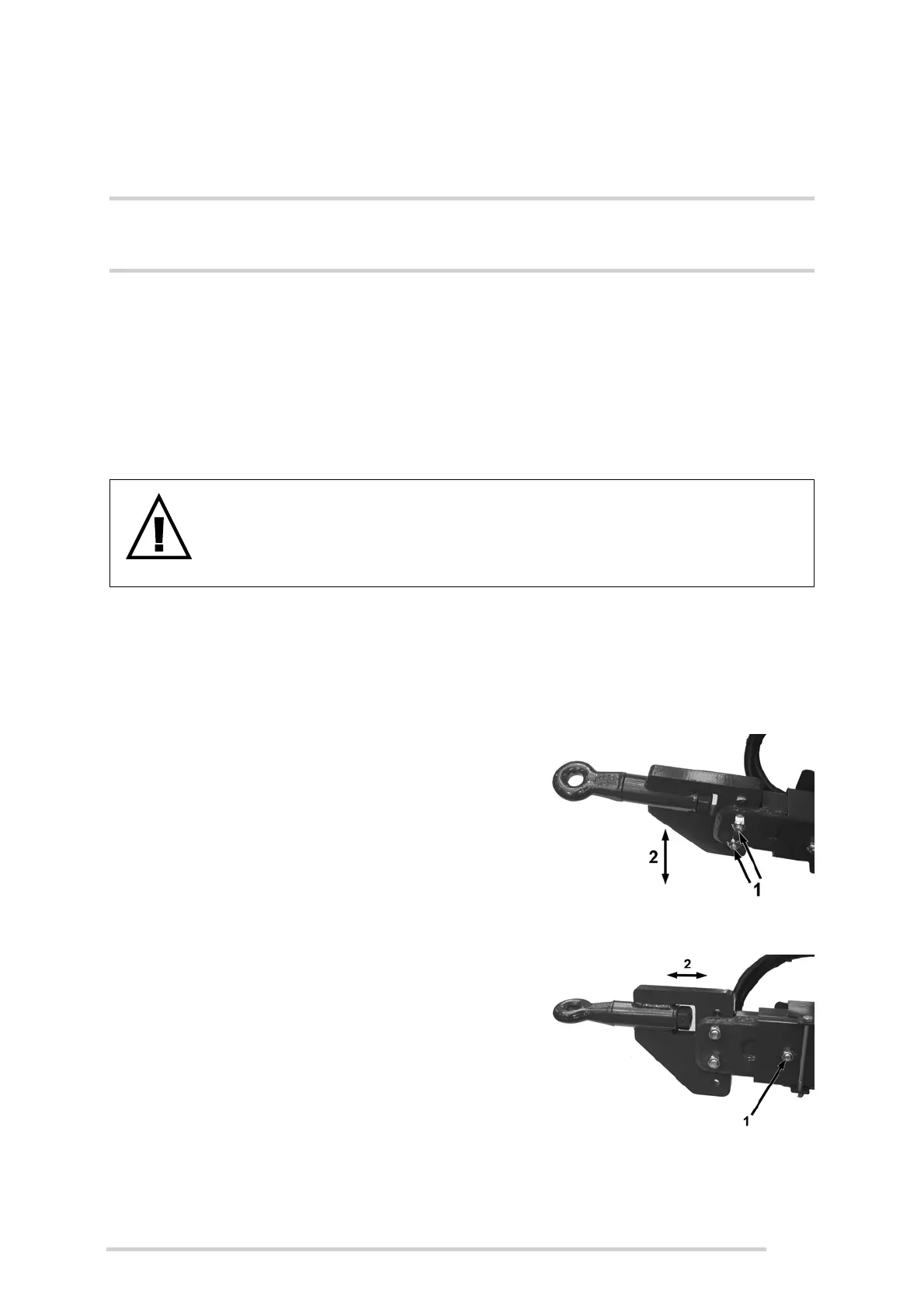

10.1 Drawbar height

The height of the drawbar may be adjusted to allow for the use with different balers and

tractors. To change the height go through the following procedure:

1. Remove 2x M20 nyloc nuts and the 2x M20

bolts holding hitch on.

2. Move hitch to new location.

3. Insert the 2x M20 bolts and tighten nyloc

nuts.

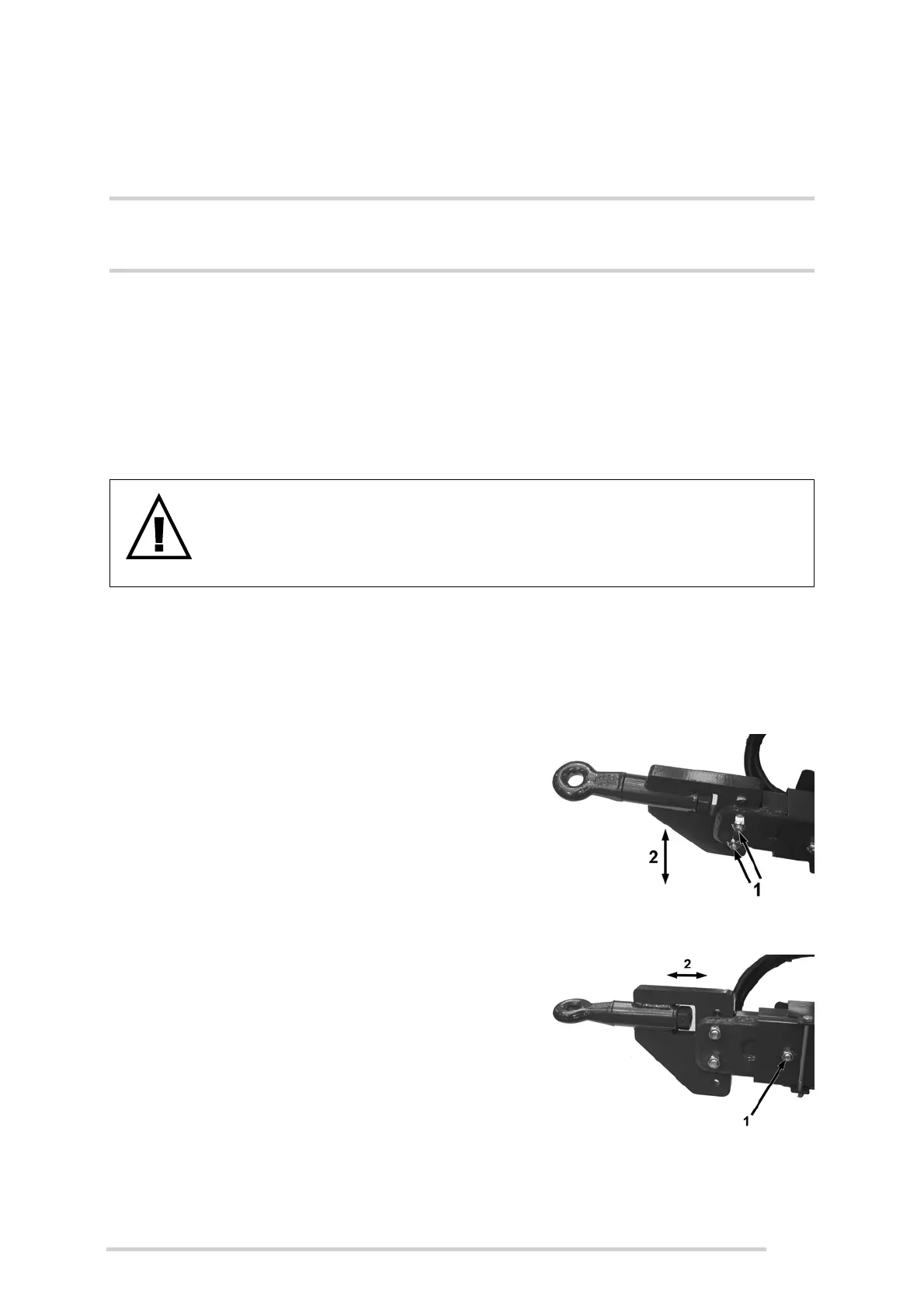

10.2 Drawbar length

It is necessary, when used on some balers, to

extend or shorten the drawbar. This may be

necessary to clear the baler when turning or to get

the bale to roll into the bale lift arm properly.

This may be set as follows:

1. Remove M16 nyloc nut holding drawbar

together and remove M16 bolt.

2. Slide inner drawbar into new position (do

not remove drawbar).

3. Insert the M16 bolt into its new position and tighten nyloc nut.

WARNING: Only competent operators should operate this machine

Always ensure that tractor is stopped, handbrake applied, engine

stopped and ignition key removed before working on machine. Always

maintain machine according to manufacturer's instructions.

Loading...

Loading...