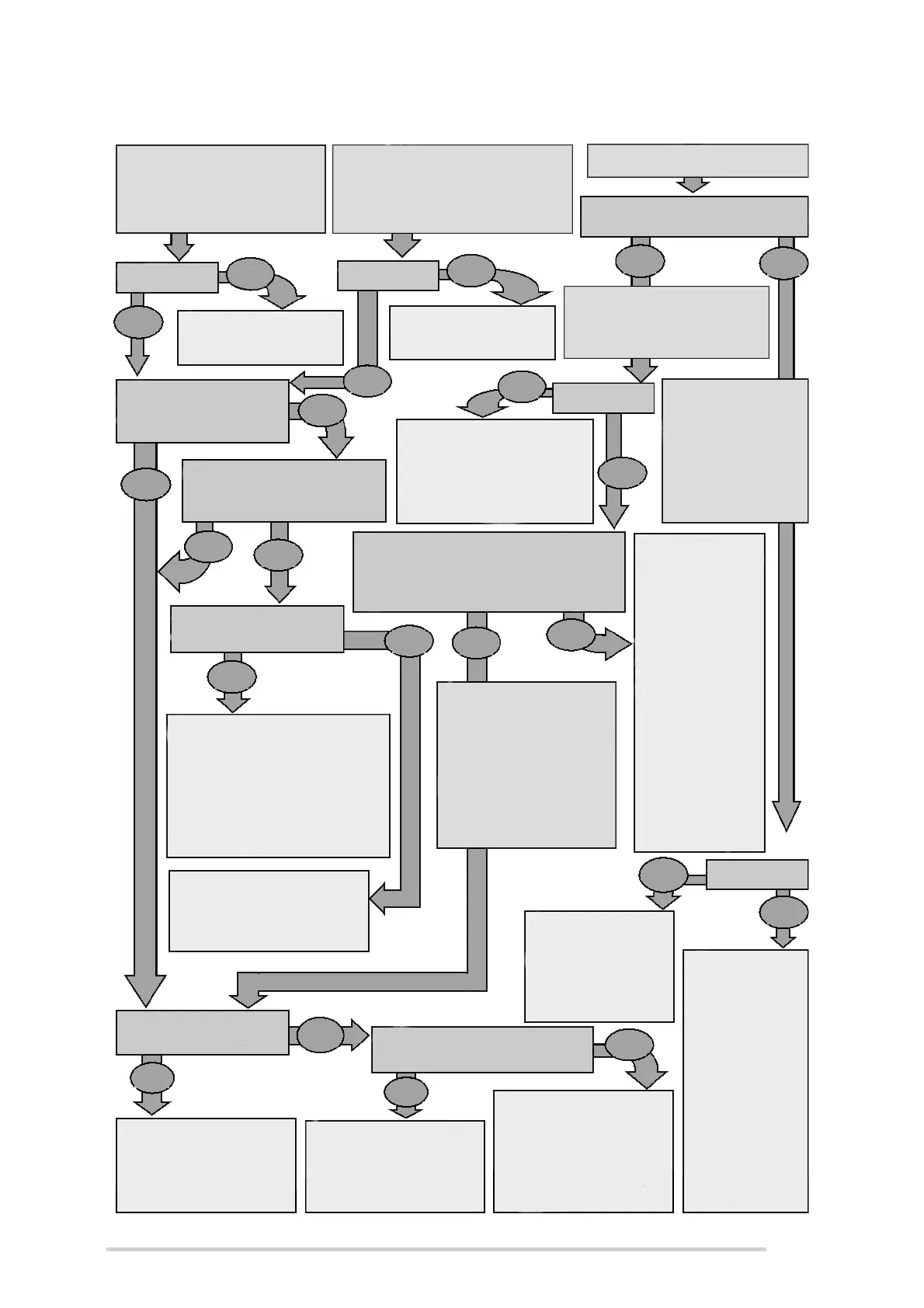

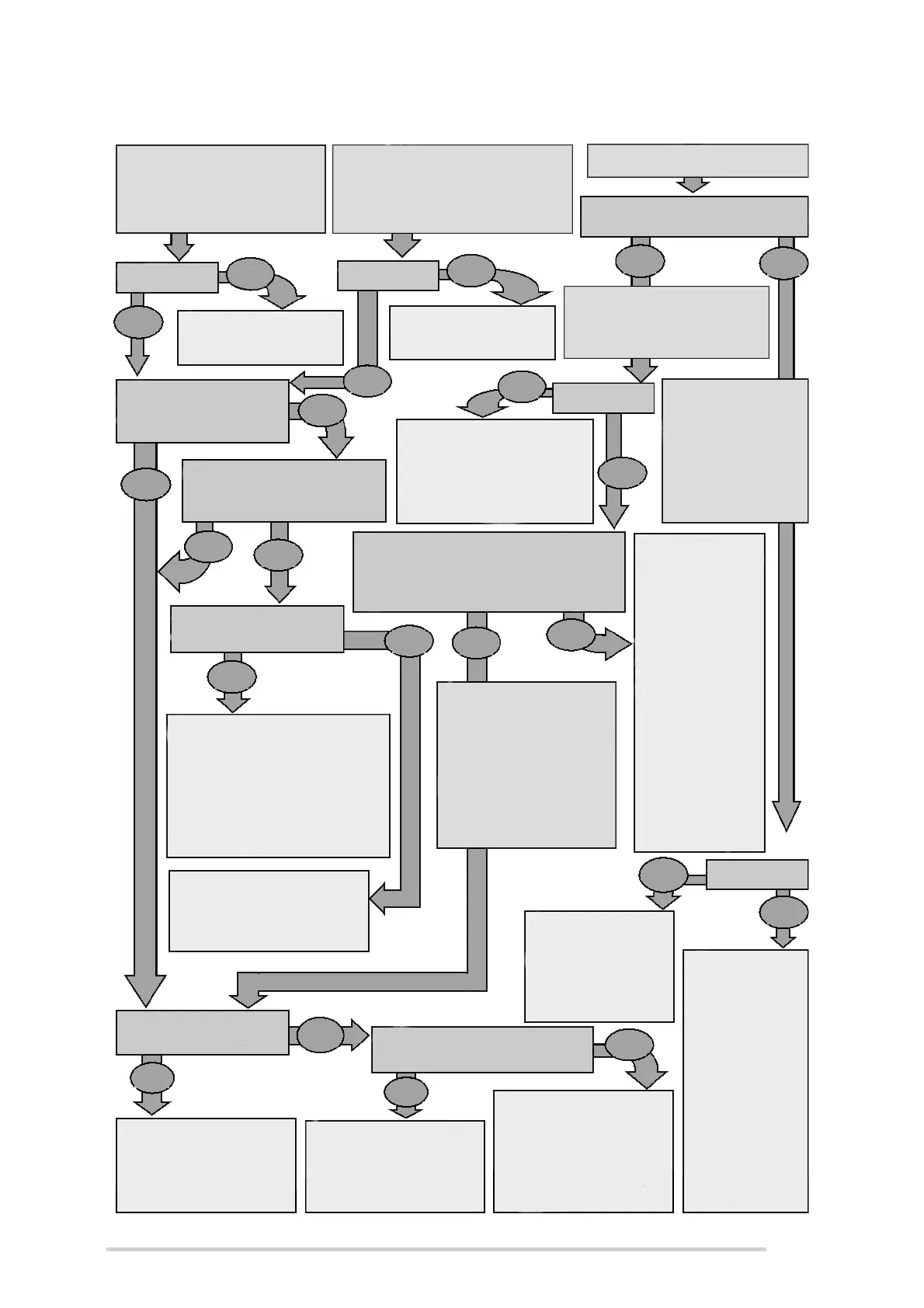

1. Open centre

Set as open centre

Default factory setting

(section 5.10)

2. Closed centre

Set as closed/load sensing

(section 5.10)

3. Load sensing

Does tractor have a Power Beyond &

sensing line connection fitted?

With baler?

Set as open centre

Default factory setting

(section 5.10)

Setup (A)

Plug wrapper feed and return

directly into wrapper

Does the tractor give a

priority oil flow to one of

the auxiliary valves?

Setup (I)

(1) Plug Wrapper Feed into tractor

spool valve

(2) Set flow on this spool to give 25-30

lit/min. to the Wrapper.

(3) Plug Wrapper Return into Free-

Flow Return on tractor.

Set as closed/load sensing

(see section 5.10)

Fit Sensing-Line hose to

drawbar steel pipe

(see section 5.11)

Can the tractor pump at least 50 lit/

min @ baler PTO speed, and has

3+ auxiliary valves?

Is each of the auxiliary valves on the tractor

‘compensated’? i.e. Can flow be set on all

spools and does not change even when two

spools are operated together?

Does the baler require a

continuous oil flow?

Setup (J)

(1) Plug Wrapper Feed

into NO. 1 auxiliary

valve. (Use hose

extension)

(2) Set flow on this spool

to give 25-30 lit/min. to

the Wrapper.

(3) Plug Wrapper Return

into Free-Flow Return

on tractor. (Use hose

extension)

(4) Plug Baler Hoses

into remaining auxiliary

valves on tractor.

(5) Set oil-flow on each

tractor spool, so that

each Baler operation

has the correct oilflow,

for that operation. i.e.

the baler door opens at

the correct speed, etc

Setup (B)

(1) Plug Wrapper Feed, directly into tractor

on the spool that gives priority over the

other spools. (Use hose extensions)

(2) Set oil-flow on this section to feed 25-

30 lit/min to wrapper.

(3) Connect Wrapper Return to free-flow

return on tractor.

(4) Connect Baler door & reel hoses to

remaining spools on tractor.

(1) Any of the following set-ups

will require the flow control /

diverter valve (CVA00025) as

outlined below.

(2) In all cases, it is very important

to set the oil flow to a maximum of

60 lit/min. Some tractors with this

hydraulic system, can supply

almost twice this amount of oil,

but this will only cause excessive

heating of the oil & higher tractor

power requirement.

Setup (C)

(1) As SET-UP (B) steps 1-3, then

proceed as below.

(2) Connect Baler Feed and Return to

remaining spool on tractor.

Setup (G)

(1) Plug Wrapper Feed into

Power Beyond Output.

(2) Plug Wrapper Return into

Free-Flow Return.

(3) Plug Sensing-Line hose

into Power Beyond

connection on tractor.

Does the baler use double-acting

cylinders to operate door?

Setup (D) (section 5.9.1)

(1) This set-up requires the use of

the flow control / diverter valve

CVA00025, as outlined on

following page.

Setup (E) (section 5.9.2)

(1) This set-up requires the use of

the flow control / diverter valve

CVA00025, as outlined on

following page.

Setup (F) (section 5.9.3)

(1) This set-up requires the use of

the flow control / diverter valve

CVA00025 & the diverter on/off

switch CEL00030 c/w loom, as

outlined on the following page.

yes

no

no

yes

no

yes

no

yes

no

yes

no

yes

no

yes

no

yes

no

yes

no

yes

no

yes

With baler?

Setup (A)

(

1) Plug wrapper feed and return

directly into wrapper

Setup (H)

(1) Plug Wrapper Feed

into Power Beyond

Output. (Use hose

extension)

(2) Plug Wrapper

Return into Free-Flow

Return. (Use hose

extension)

(3) Plug Sensing-Line

hose into Power

Beyond connection on

tractor. (Use hose

extension)

(4) Plug Baler Hoses

into auxiliary valves on

tractor as normal, i.e.

fit Baler as if no

Wrapper was attached.

With baler?

With baler?

Does the baler require a

continuous oil flow?

Loading...

Loading...