Section 9: Water Side Treatment

The brazed plate heat exchanger (BPHE) which is used in the mini chiller unit consists of

several stainless steel plates brazed together to form two distinct flow channels in between

each successive plates. Water flows in one channel and refrigerant in the other, usually in a

counter flow

direction.

Because the spacing in between the plates is small, it is vital that these flow channels

(especially the water side) are not blocked by debris, fouling or scaling. Such impurities will

restrict the flow rate and reduces the chiller performance. Furthermore, the heat transfer

efficiency will be retarded.

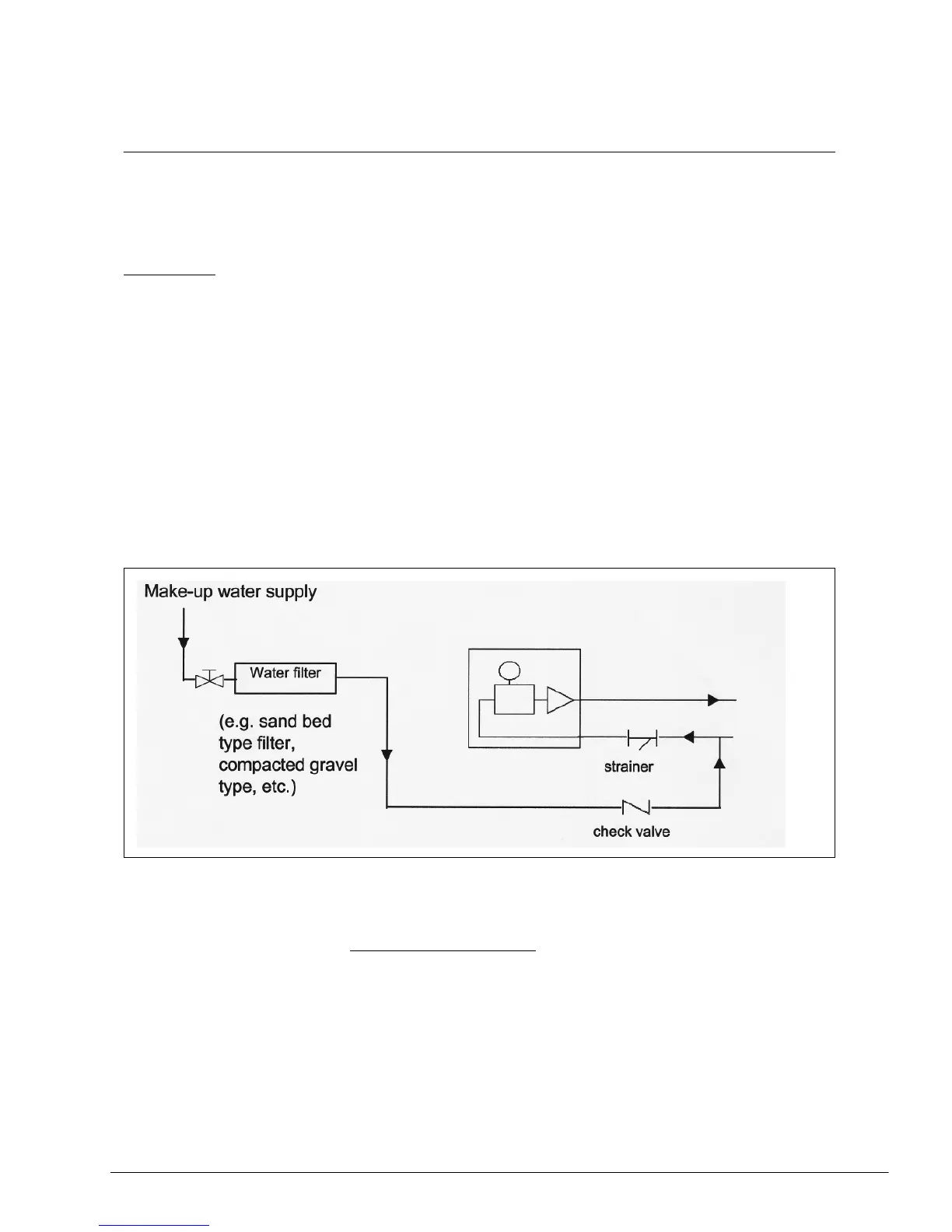

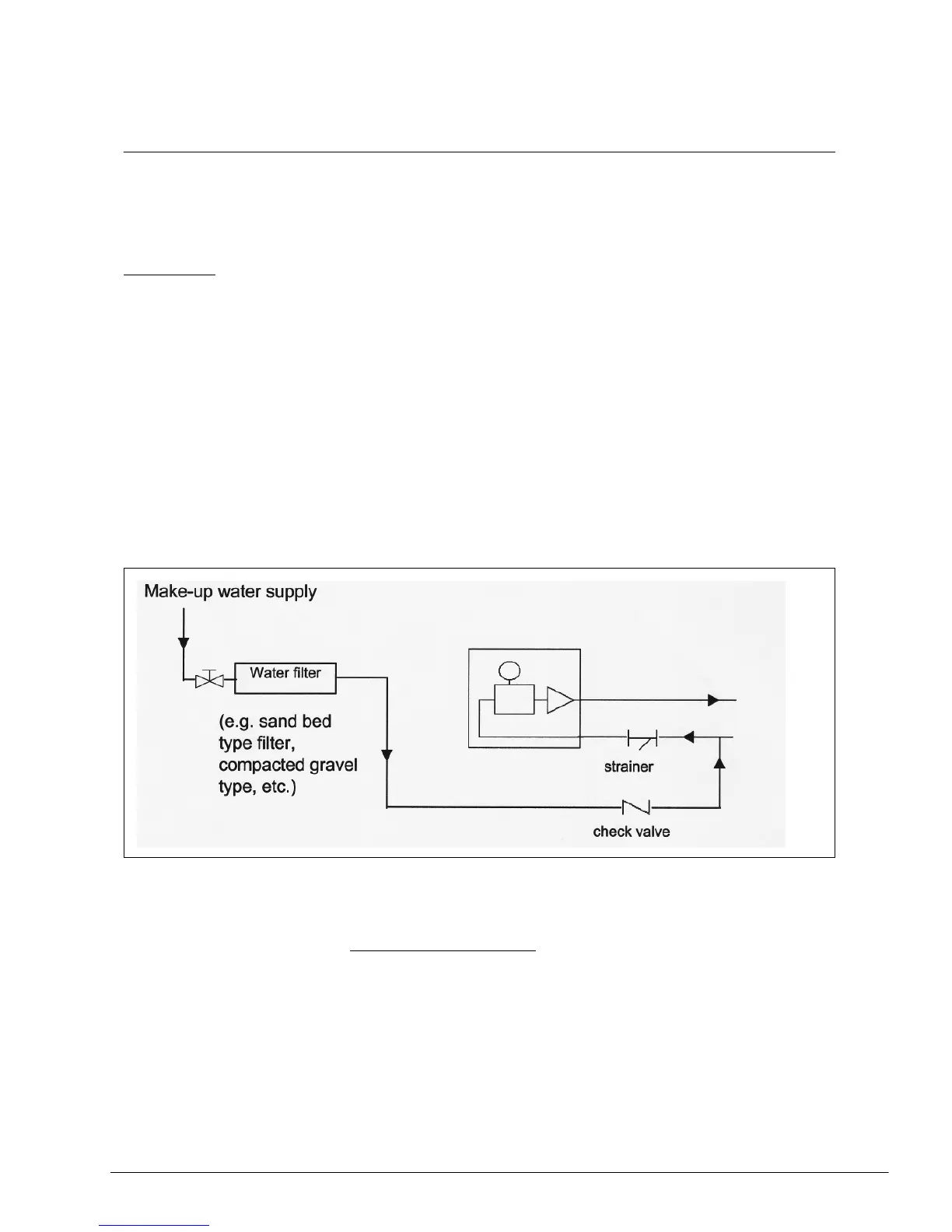

Generally, debris in the water (e.g. sand, gravel, metal pieces) will be removed by the

strainer installed along the water suction pipe. This will depend on the filter mesh size used

in the strainer itself. A filter mesh size of 16 - 20 is recommended for this purpose.

Nevertheless, it is also a good practice to install another water filter along the make-up

water supply pipe for the same purpose.

It is important that these filter elements to be serviced periodically to remove any trapped

particles and debris inside them. Flushing of the pipes periodically with water is also a good

maintenance practice.

Usually, such coarse debris are found during initial start-up and commissioning of the mini

chillers. These debris are left-overs during the installation of the water piping. Therefore, it is

recommended that a thorough flushing with clean water

to be done in the water piping before

the chiller is started. Check and clean the strainer element also before start-up. Fouling refers to

the tendency of the water to form a film on the heat transfer surfaces. There are two types of

fouling:

a. Organic surface fouling

b. Inorganic suface fouling

Section 9 Page 108

Loading...

Loading...