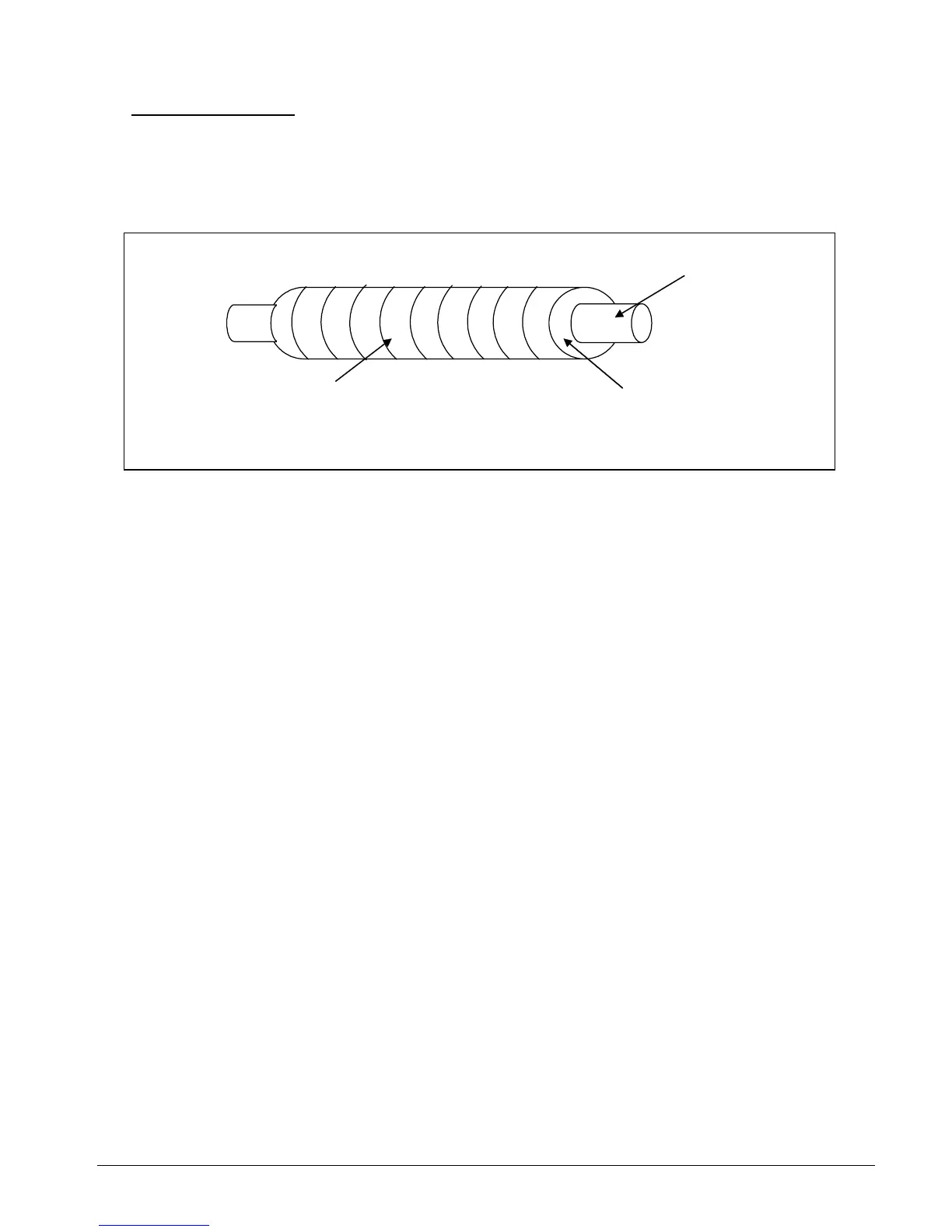

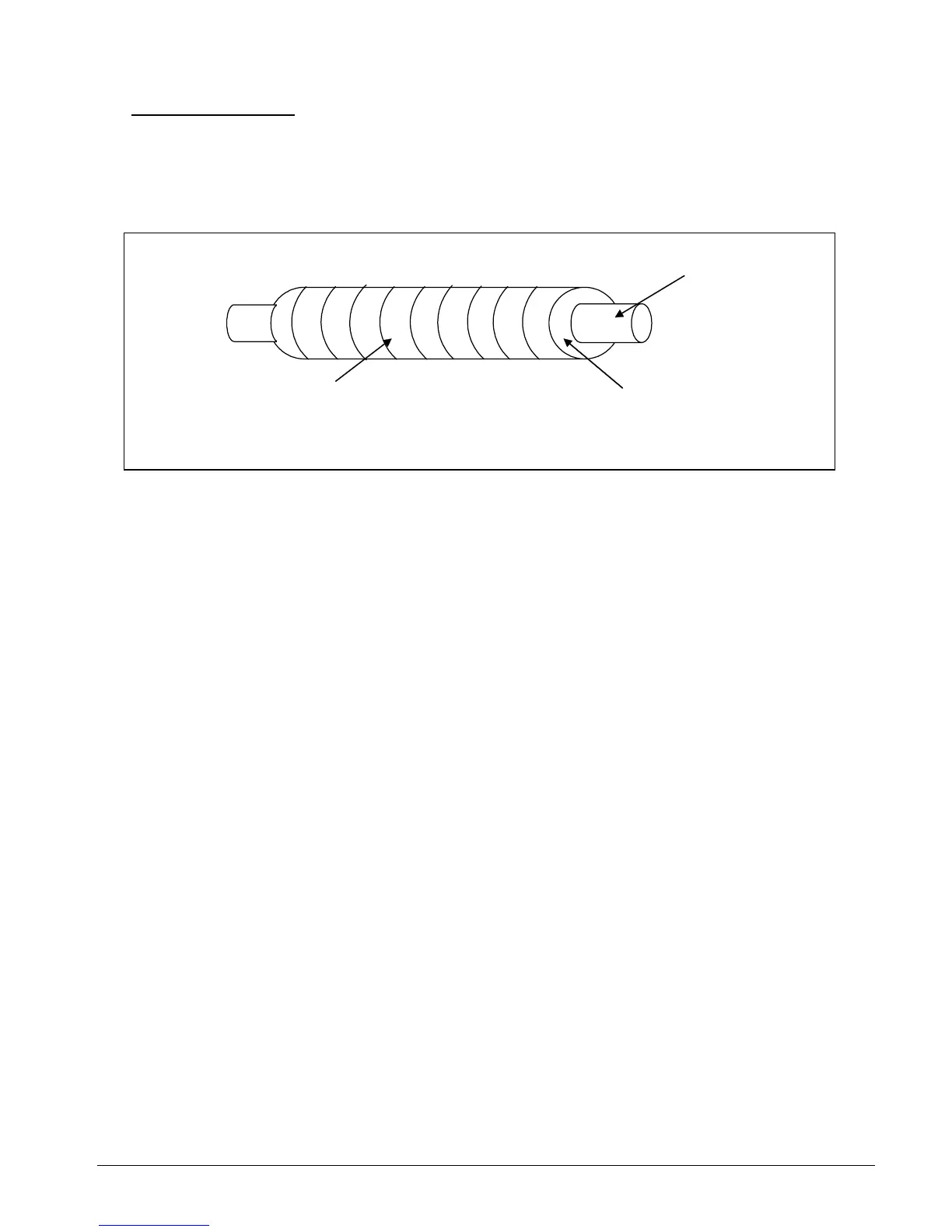

Pre-Insulated Pipes

These are black steel pipes which have been injected with polyurethane foam together

with an external spirally wound metal cladding (aluminium or galvanised iron). Because

these pipes have been pre-fabricated, they are widely used in the installation of chillers.

The insulation forms a rigid and strong bond with the pipe surface.

black steel pipe

external metal polyurethane

cladding

(spiral wound)

Pipes can be joined together with arc welding.

Advantages:

a. Due to the strong bond of the polyurethane, there are no air leakages through the

insulation and cause internal condensation.

b. The metal cladding gives a good finishing to the installation. Paint can be applied

easily over the metal, providing protection against corrosion and giving colour codes to the

different pipes used.

Disadvantages:

a. High cost.

b. Joints with fittings and between pipes require additional insulation moulding. This is done

by making a mould with thin metal sheets (aluminium or GI) around the fitting or pipe joint.

A mixture of polyurethane chemical and foaming agent is then poured into the mould and

allowed to fill the mould.

Pre-fabricated pipe sectional polyurethane can also be used for this purpose, e.g. for elbows

and straight pipe joints. An external metal cladding can then be rivetted around these

sections.

As a result of this, the installation of such insulation is more extensive and requires skill.

Section 7 Page 97

Loading...

Loading...