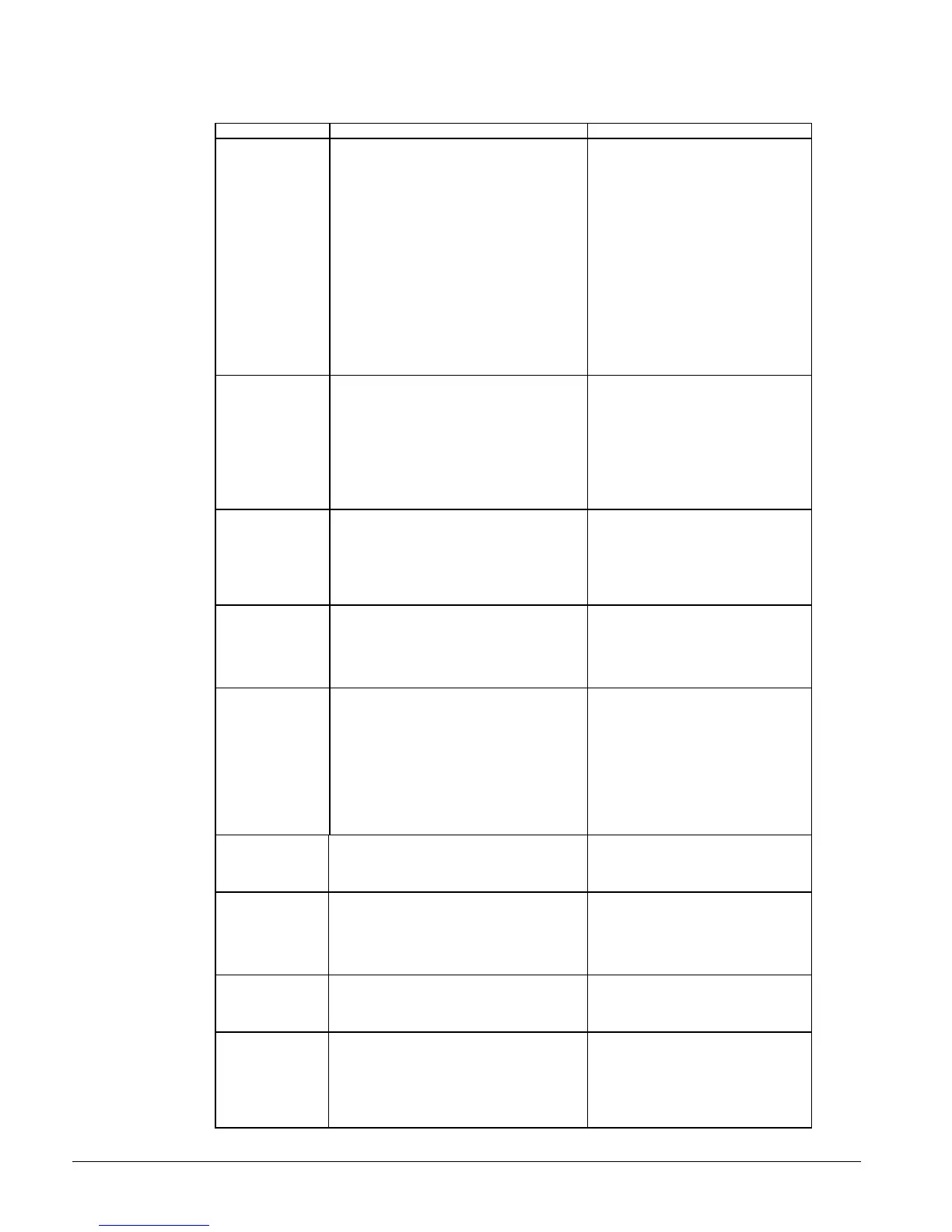

60 IOMM ACZ/AGZ-1

Global UNT Controller Troubleshooting Chart

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTIONS

Compressor will

not run

1. Main switch, circuit breakers open.

2. Fuse blown.

3. Thermal overloads tripped or fuses

blown.

4. Defective contactor or coil.

5. System shut down by safety devices.

6. No cooling required.

7. Liquid line solenoid will not open.

8. Motor electrical trouble.

9. Loose wiring.

1. Close switch.

2. Check electrical circuits and motor

winding for shorts or grounds.

Possible overloading. Replace fuse

or reset breakers after fault is

corrected.

3. Overloads are auto reset. Check

unit closely when operating again.

4. Repair or replace.

5. Determine type and cause of

shutdown and correct it before

resetting safety.

6. None. Wait for load.

7. Repair or replace.

8. Check motor for opens, shorts

circuit or burnout.

9. Check all wire junctions. Tighten

all terminals.

High Discharge

Pressure

1. Dirty condenser coils.

2. Fan not operating.

3. High Ambient conditions.

4. High return water temperature.

5. Overcharge of refrigerant.

6. Non condensable.

7. Discharge valve partially closed.

1. Clean.

2. Check fan motor, contactor,

contactor coil, fan pressure switch.

Repair or replace defective part.

3. Check against design conditions.

4. Disable a compressor on each.

5. Remove excessive amount of

charge.

6. Remove non condensable.

7. Back seat valve

Low Discharge

Pressure

1. Fan contactor failed in closed position.

2. Fan pressure switch defective.

3. Low ambient temps.

4. Low on refrigerant charge.

5. Reduced chilled water flow.

6. No load and on hot gas bypass.

1. Repair or replace.

2. Replace pressure switch.

3. Install SpeedTrol Kit.

4. Add refrigerant.

5. Check flow and correct.

6. Adjust hot gas bypass to maintain a

higher evaporator pressure.

High Suction

Pressure

1. Excessive load (high return water temp).

2. Controller not staging up.

3. Compressor capacity reduced.

4. Can be associated with high condenser

pressure.

1. Check water flow, reduce load.

2. Check UNT controller. Replace if

defective.

3. Replace compressor.

4. Check reasons for high condenser

pressure.

Low Suction

Pressure

1. Low refrigerant charge.

2. Defective expansion valve.

3. Dirty filter drier.

4. Reduced water flow.

5. Hot gas bypass valve not set properly.

6. Liquid line solenoid valve not opening.

7. UNT controller defective.

8. Gasket failure in evap head ring.

1. Add refrigerant.

2. Check operation. Repair or

replace.

3. Replace cores.

4. Increase water to design GPM.

5. Set valve for a higher pressure.

6. Repair or replace.

7. Check water sensor, set point dial,

control band dial. Calibrate, repair

or replace.

8. Replace gasket.

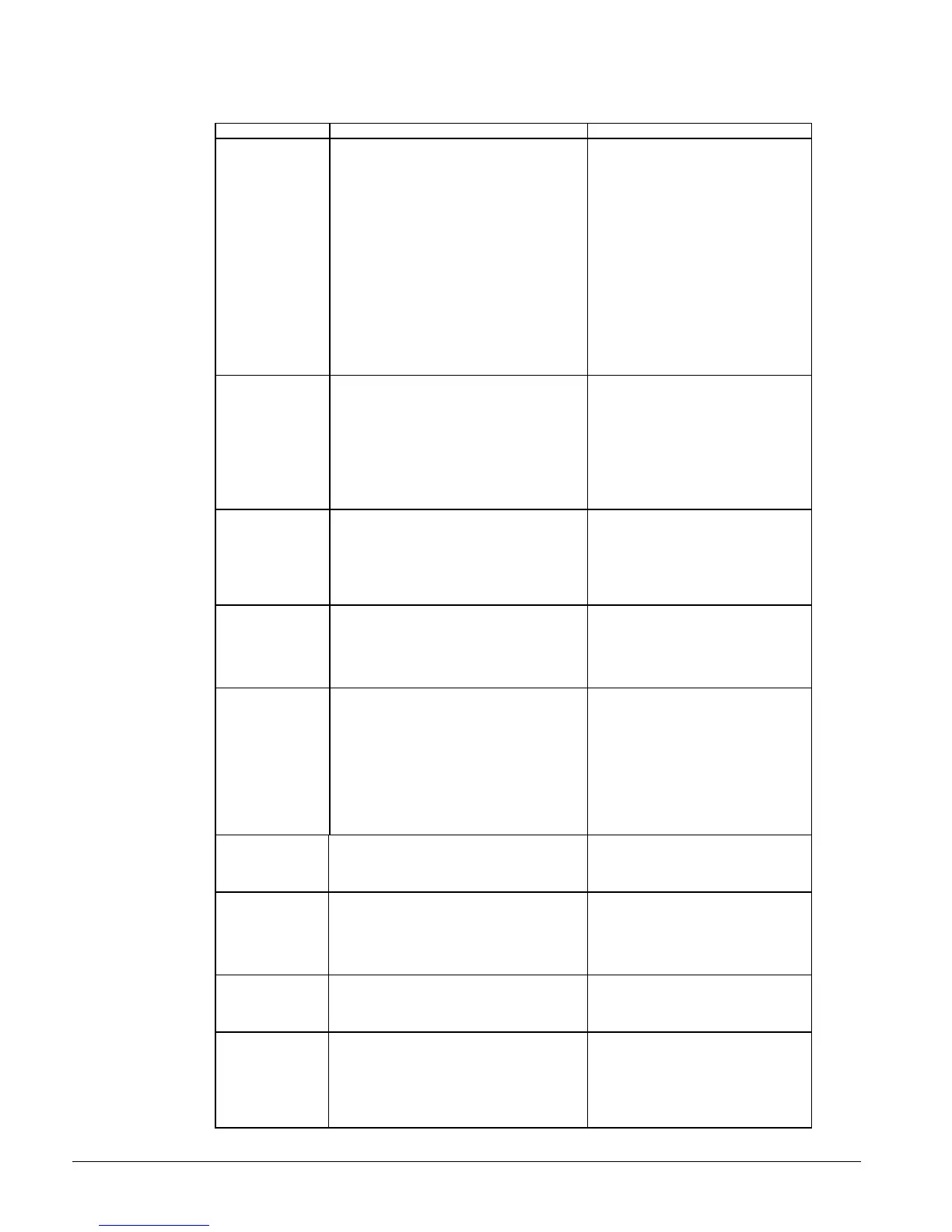

Compressor Oil

Loss

1. Excessive refrigerant flood back.

2. Defective crankcase heater.

3. Low refrigerant charge.

4. Hot gas bypass not set properly.

1. Check TXV. Repair or replace.

2. Replace heater.

3. Add refrigerant.

4. Increase hot gas flow.

Compressor

Overloads or

Circuit Breakers

Open

1. Low line voltage.

2. High compressor amps.

3. Loose power wiring.

4. High condenser pressures.

5. Single phasing.

1. Check incoming voltage. Report to

electrical supplier.

2. Determine cause and correct.

3. Tighten all connections.

4. Refer to High Condenser Pressure.

5. Replace fuses or breaker.

Compressor

Internal Motor

Switch Open

1. Compressor amps high.

2. Motor winding damaged.

1. Refer to the above concerning high

compressor amps.

2. Check motor winding resistance.

Replace if defective.

Freeze Protection

Trips

1. Pressure transducers defective.

2. Low water flow.

3. Low loads / erratic water flow.

4. Controller stage timing.

5. Defective TXV.

1. Compare output to actual

refrigerant pressures.

2. Check water GPM and correct.

3. Check pump operation, water

strainer, air handler control valves.

4. Check timing and reset as

necessary.

Loading...

Loading...