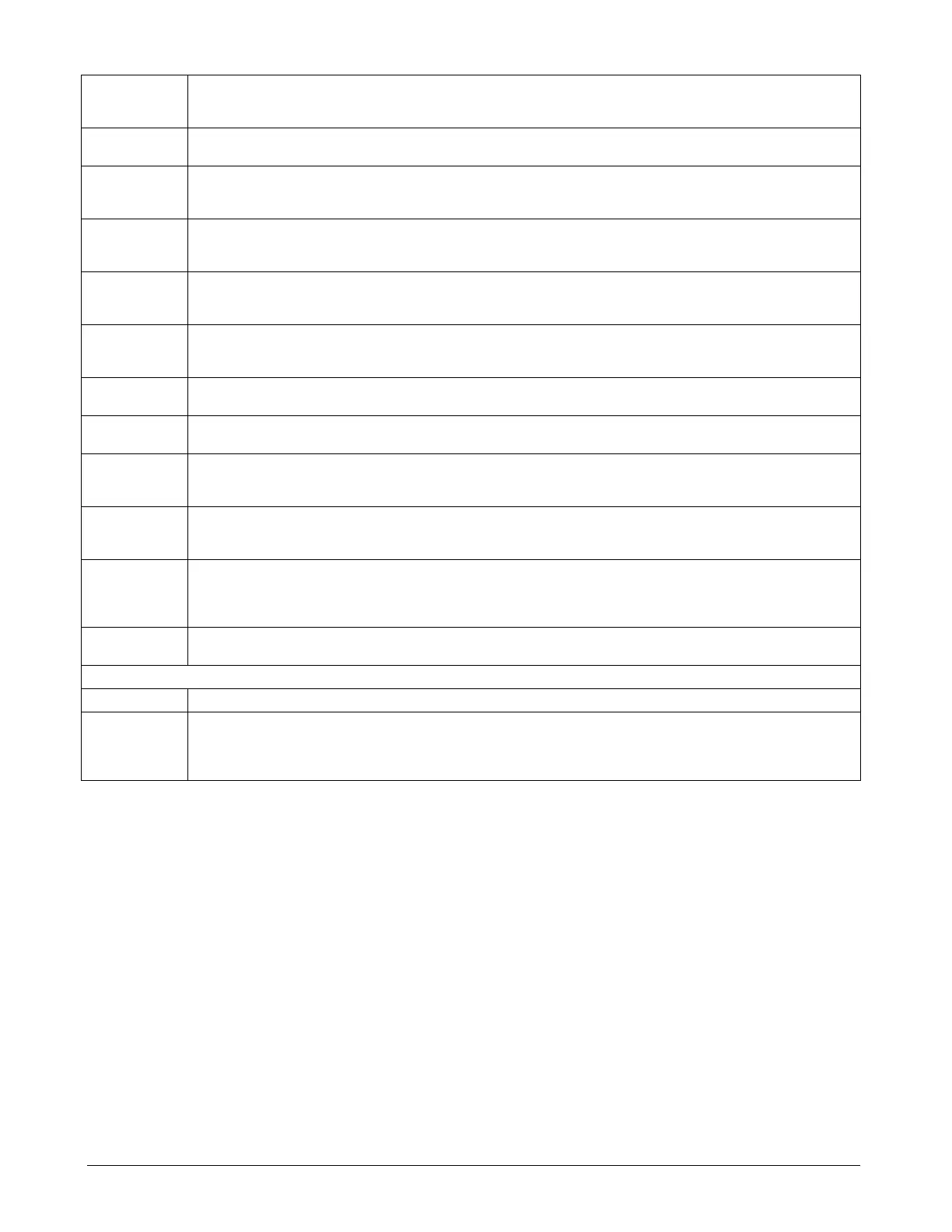

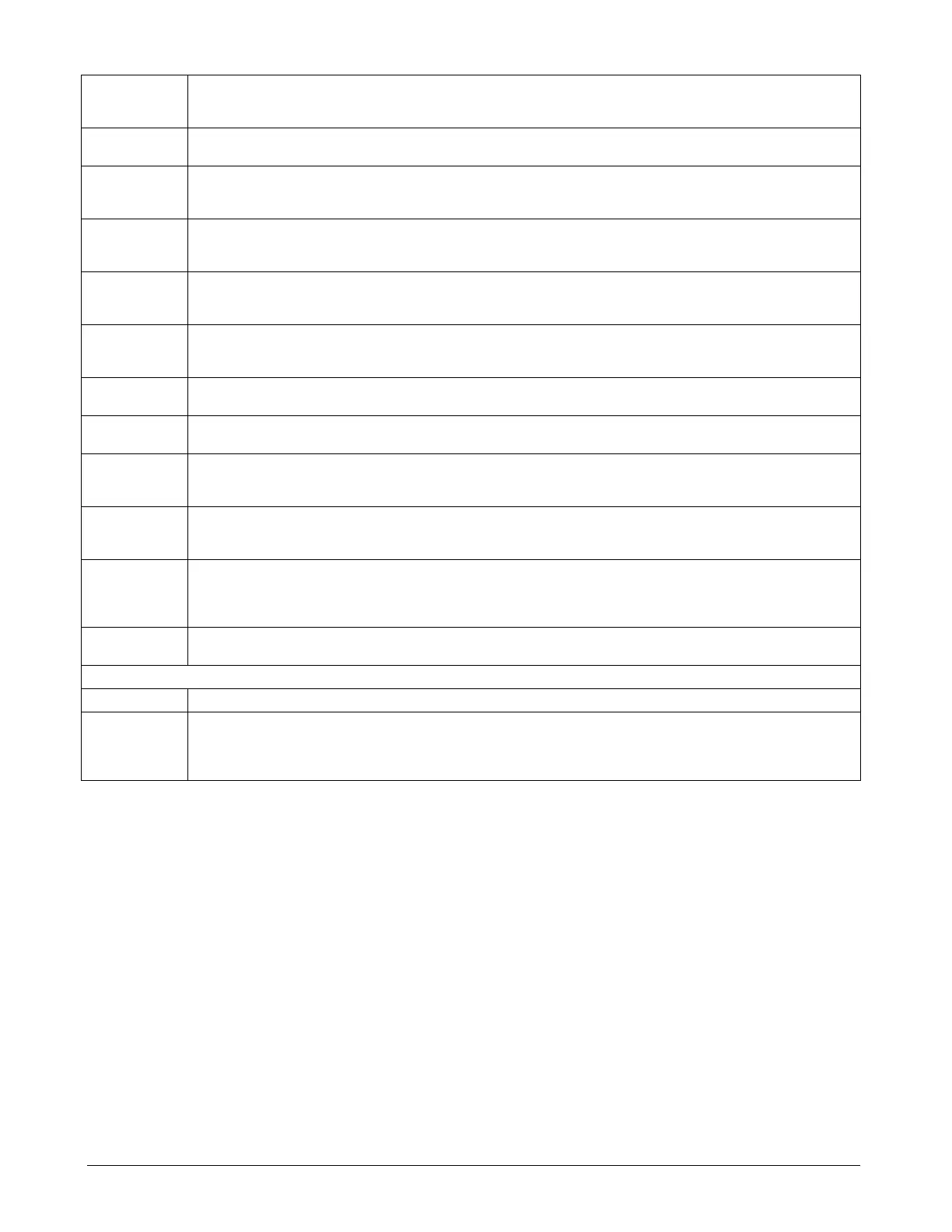

Page 58 OM 780-2

Max Tower

Valve Position

Setpoint

This value is used as a stage-up condition for interstage and low limit control when a tower valve is used (the CSM will not

increase the tower stage until the valve position is greater than this setpoint). Range = 0% - Tower Valve Control Range Max.

Default = 80%

Tower Valve

Type

Defines whether the tower bypass valve is normally open or normally closed to the tower. Range = NC to Tower, NO to Tower.

Default = NO to Tower

Tower Valve

Deadband

This value sets a Deadband around the Tower Valve Setpoint if a tower valve is used. No tower valve control action is taken when

the current Control Temperature is within this Deadband around the Tower Valve Setpoint. Range = 0 – 9.5°F (0 – 5.2°C).

Default = 2°F (1.1°C)

Tower Valve

Propband

This value sets the “proportional band” used in the PID control function that modulates the tower valve position. In general,

increasing this value has a slowing effect and decreasing this value has a speeding effect on the control of the valve position.

Range = 1 – 60°F (0.5 – 33.3°C). Default = ±7.5°F (±4.1°C)

Tower Valve

Sample Time

This value sets the “sampling period” used in the PID control function that modulates the tower valve position. In general,

increasing this value has a slowing effect and decreasing this value has a speeding effect on the control of the valve position.

Range = 1 – 3600 seconds. Default = 15 seconds

Tower Valve

Integral Time

This value varies the “integral time” used in the PID control function that modulates the tower valve position. In general,

increasing this value has a slowing effect and decreasing this value has a speeding effect on the control of the valve position.

Range = none. Default = 120 seconds

Tower Valve PI

Function Graph

A graph of the tower Control Temperature vs. Time is shown at the bottom of the page when the Tower Valve Control Option is

not equal to “None”, to assist in tuning the Tower VFD PI loop.

Min Tower Valve

Start Up Position

Used to define the initial tower valve position (before any chillers enter the Running mode). See the Start-Up Valve Position

Control section of this document. Range = Tower Valve Control Range Min – to - 100%. Default = 0%.

Max Tower

Valve Start Up

Position

Used to define the initial tower valve position (before any chillers enter the Running mode). See the Start-Up Valve Position

Control section of this document. Range = 0% - Tower Valve Control Range Max. Default = 100%.

Min Tower Valve

Start Up Position

@ (OAT)

Used to define the initial tower valve position (before any chillers enter the Running mode). See the Start-Up Valve Position

Control section of this document. Range = 0-120 °F (-17.8 – 48.8°C). Default = 60°F (15.5°C)

Max Tower

Valve Start Up

Position @

(OAT)

Used to define the initial tower valve position (before any chillers enter the Running mode). See the Start-Up Valve Position

Control section of this document. Range = 0-120 °F (-17.8 – 48.8°C). Default = 90°F (32.2°C)

Tower Stage

Table

Pressing this button takes you to the Cooling Tower Sequence Order Table.

Cooling Tower Output Sequence Order Table

Name Description

Stage 1, Output 1

Stage 1, Output 2

Stage x, Output y

This table is used to assign tower outputs to cooling tower stages. Setting a tower output to ON in a stage #’s row will close the

associated relay whenever that particular tower stage is reached.

The CSM can control a cooling tower system that has up to 12 stages of heat rejection. It can also control a tower bypass

valve, but this is not required.

A typical condenser water loop is shown in the Figure 23. Notice that the condenser pumps at the chillers pump water

through the system. The CSM does not directly control the operation of these pumps; the chiller controllers do.

When to Use the CSM’s Cooling Tower Control

MicroTech II water-cooled chiller unit controllers and the CSM both have cooling tower control capability. If the cooling

tower system is piped so that it is common to all chillers, you should use the CSM for cooling tower control. This type of

configuration is shown in Figure 23. If each chiller has a dedicated cooling tower, you should use the chiller controllers for

cooling tower control.

Loading...

Loading...