IM 985-1 / Page 5 of 36

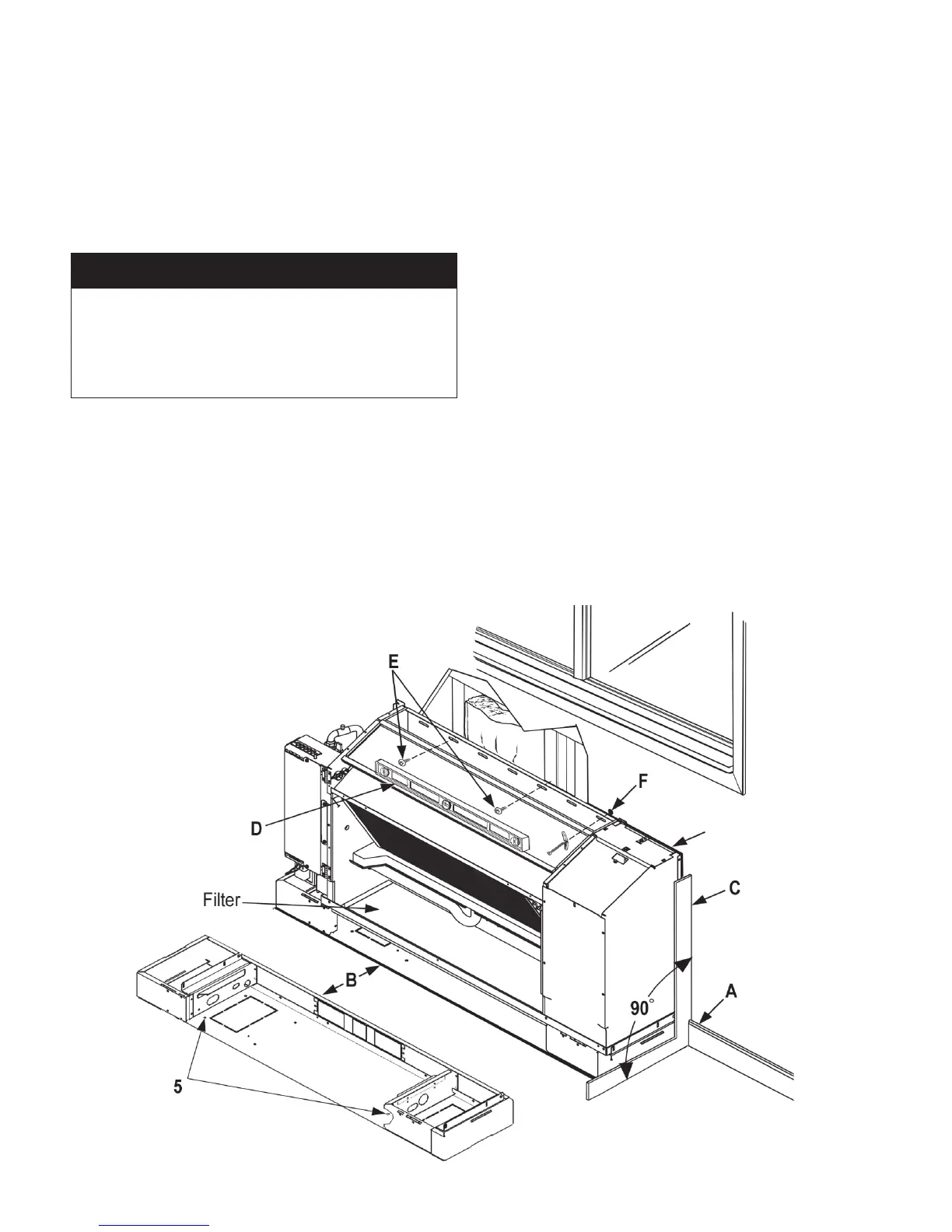

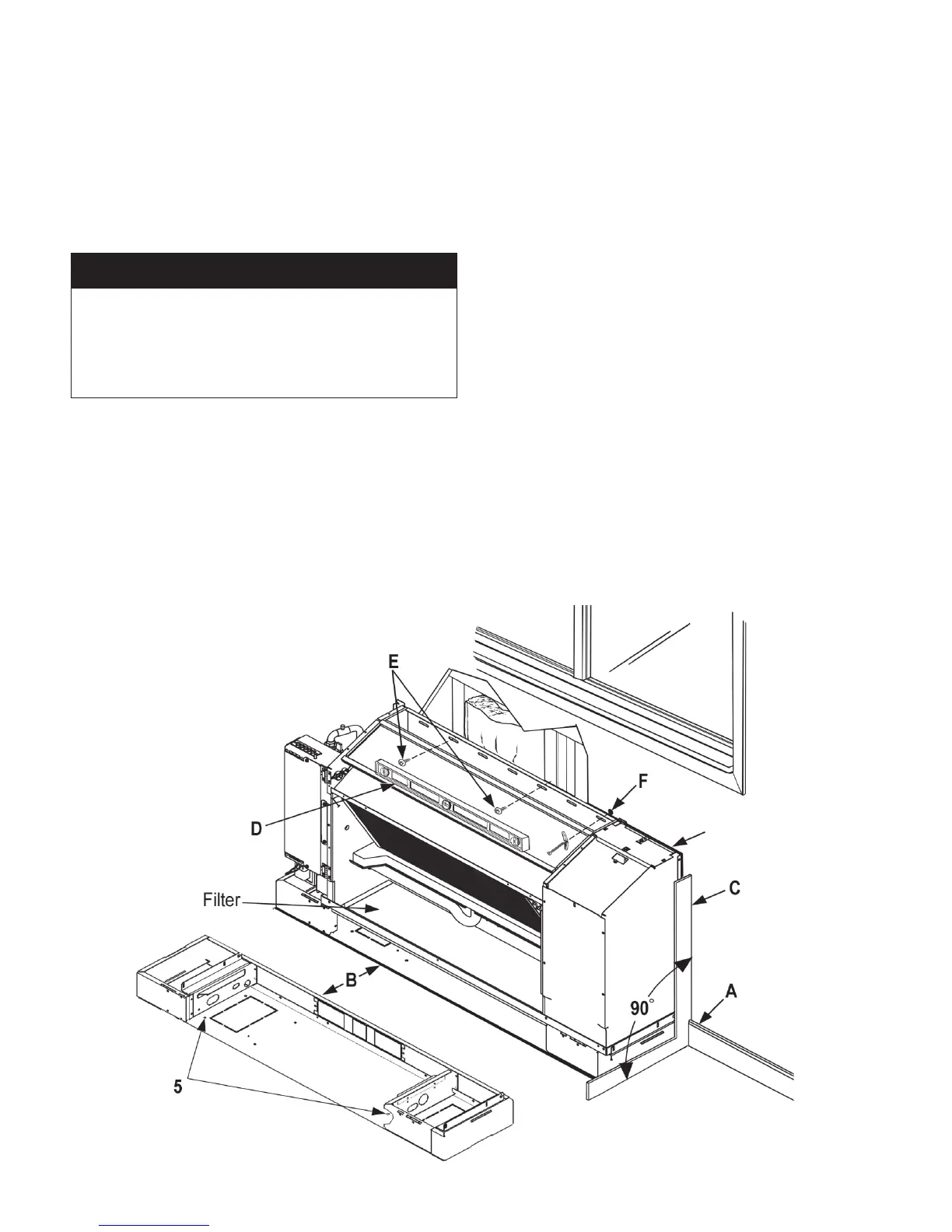

Figure 2. Unit Mounting Details

7. Removethelterandlocatetheexisting1/4"

mounting holes in the bottom of the subbase labeled

(5) in Figure 2 subbase detail.

8. Be sure the subbase is tight to the wall. Transfer

amarkwithamarkerorpenciltotheoorat

mounting hole locations (5).

9. Moveunitawaytopre-drill1/4"mountingholesin

theooratmarkedlocations.

Clean unit mounting area of all construction debris. Check

that the floor is level and at 90 degrees to the wall as

shown in Figure 2.

McQuay recommends the placement of a sound absorbing

mat beneath the unit footprint before continuing to the next

installation step.

Note: Use the appropriate fasteners by others in

accordance with local building codes.

10. Insert fasteners through the mounting holes in

thesubbaseandsecurethesubbasetotheoor,

tightening the fasteners. Do not over-tighten

fasteners and distort or warp the subbase plate.

IMPORTANT

11. Use a carpenters square and level to check that the

unitisleveland90-degreestothewallandoor(see

letters C & D in Figure 2).

12. The chassis back panel has a series of slots on the

backangetomounttheassemblytothewall.Itis

the installing contractor’s responsibility to select the

correct fasteners for each unit to meet local codes

(see letter E in Figure 2).

Note: Use a minimum of three fasteners to secure

the unit (eld supplied). Secure two fasteners into

wall studs.

At location(s) where no stud is present, secure with

a Toggle bolt or equivalent (by others) (see letter F

in Figure 2).

13

. Reinstall the panels in reverse order as performed in

steps 3 through 5 on page 4.

14. Cut out one side and the bottom of the shipping

carton, leaving the top and three sides to place over

the unit for protection during construction.

Loading...

Loading...