IM 985-1 / Page 7 of 36

Note: Be sure that one end of the hose has a swivel

tting to facilitate removal for service. Hard piping to

the unit can result in added operating noise.

4. Ifsealantcompoundisnotprovidedforexiblehose

ttings,applyTeontapetotheconnectionstohelp

prevent leaks.

5. Supply and return shutoff valves are required at each

unit. The return valve is used for balancing and

should have a “memory stop” so that it can always

be closed off, but can only be re-opened to the

properpositionfortheowrequired.

6. Do not connect a unit to the supply and return

piping until the water system has been cleaned and

ushedcompletely.Afterthisisdone,theinitial

connection should have all valves wide open in

preparationforwatersystemushing.

7. Condensate piping can be steel, copper, or PVC.

Each unit is supplied with a clear vinyl condensate

hose.

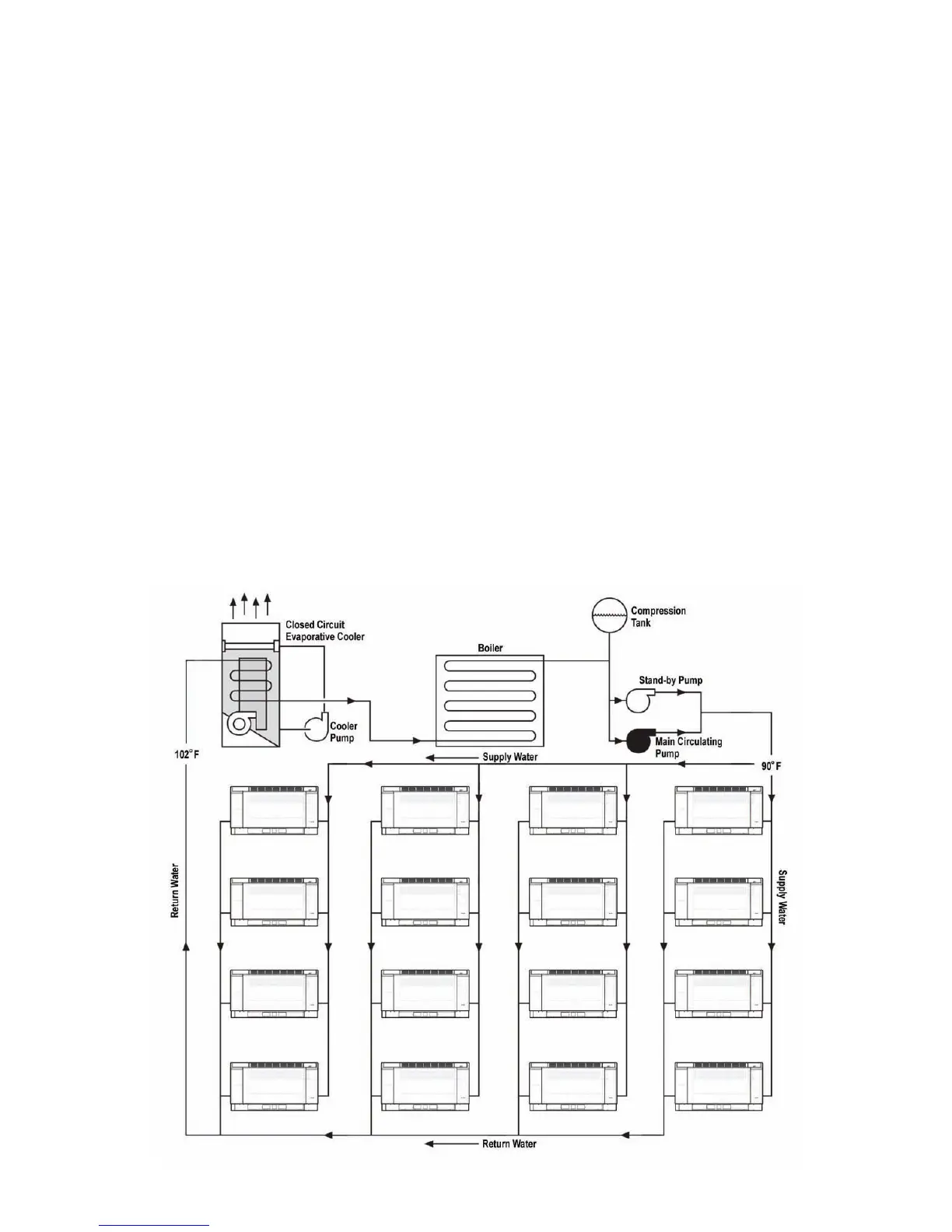

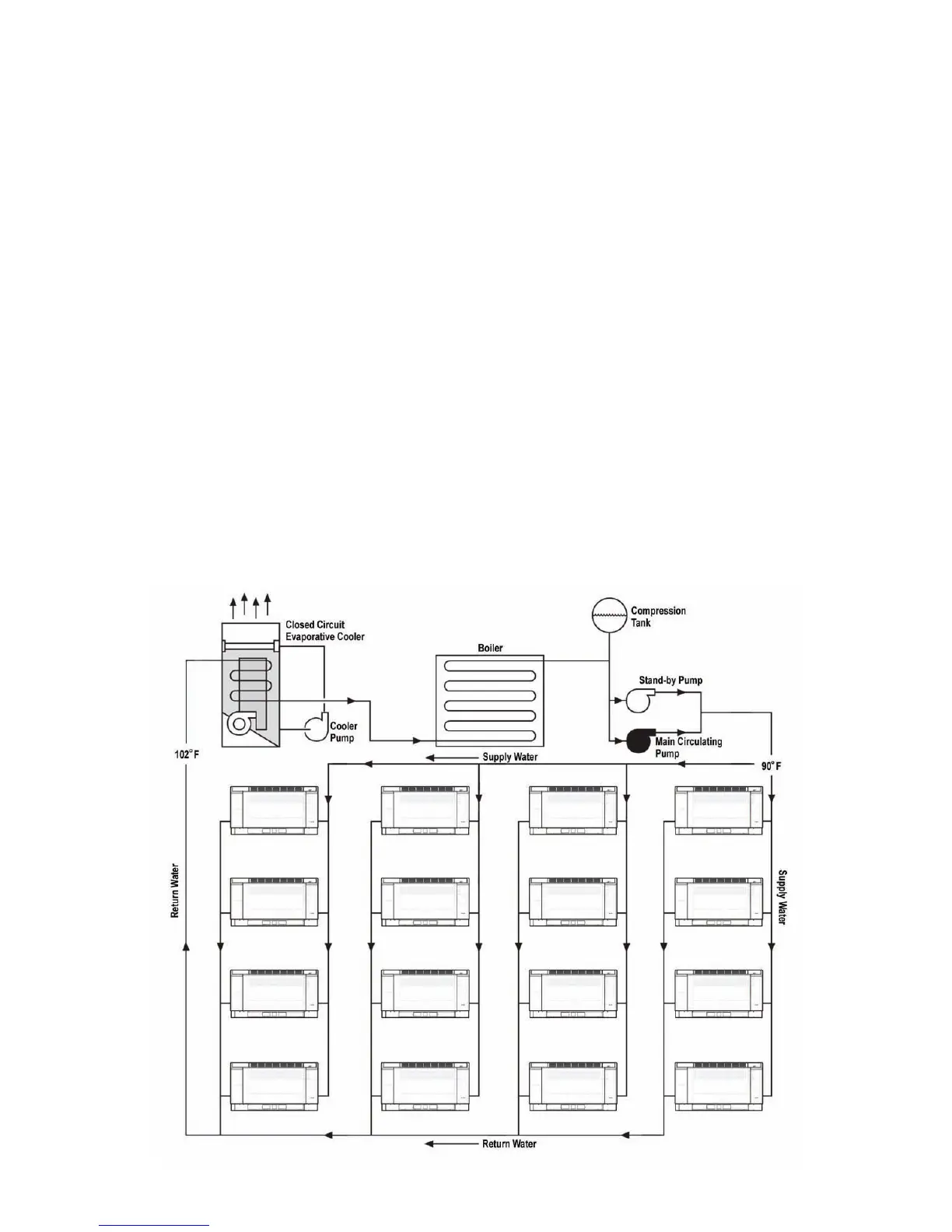

Figure 4. Typical 2-Pipe Reverse Return Conguration

Piping

1. Connect units to supply and return piping in a two-

pipereversereturnconguration(Figure4).

A reverse return system is inherently self-balancing

and requires only trim balancing where multiple

quantitiesofunitswithdifferentowandpressure

drop characteristics are connected to the same loop.

A simple way to check for proper water balance is

to take a differential temperature reading across the

water connections when in the cooling mode. To

achieveproperwaterow,thedifferentialshouldbe

10°F to 14°F (-5°C to -8°C).

A direct return system may also be acceptable, but

properwaterowbalancingismoredifcultto

achieve and maintain.

2. The piping can be steel, copper or PVC, but must

comply with local codes.

3. Supply and return run outs are typically connected

totheunitbyshortlengthsofhighpressureexible

hose which are sound attenuators for both unit

operating noise and hydraulic pumping noise.

Loading...

Loading...