21

Recommendations for

selection of test

voltage and duration

Before one starts the actual test, the currently set test parameters should be checked and

adapted if needed.

The requirements for a meaningful cable test are found in Harmonization Documents

HD 620 S1:1996 and HD 621 S1:1996 and often in company-internal testing guidelines as

well.

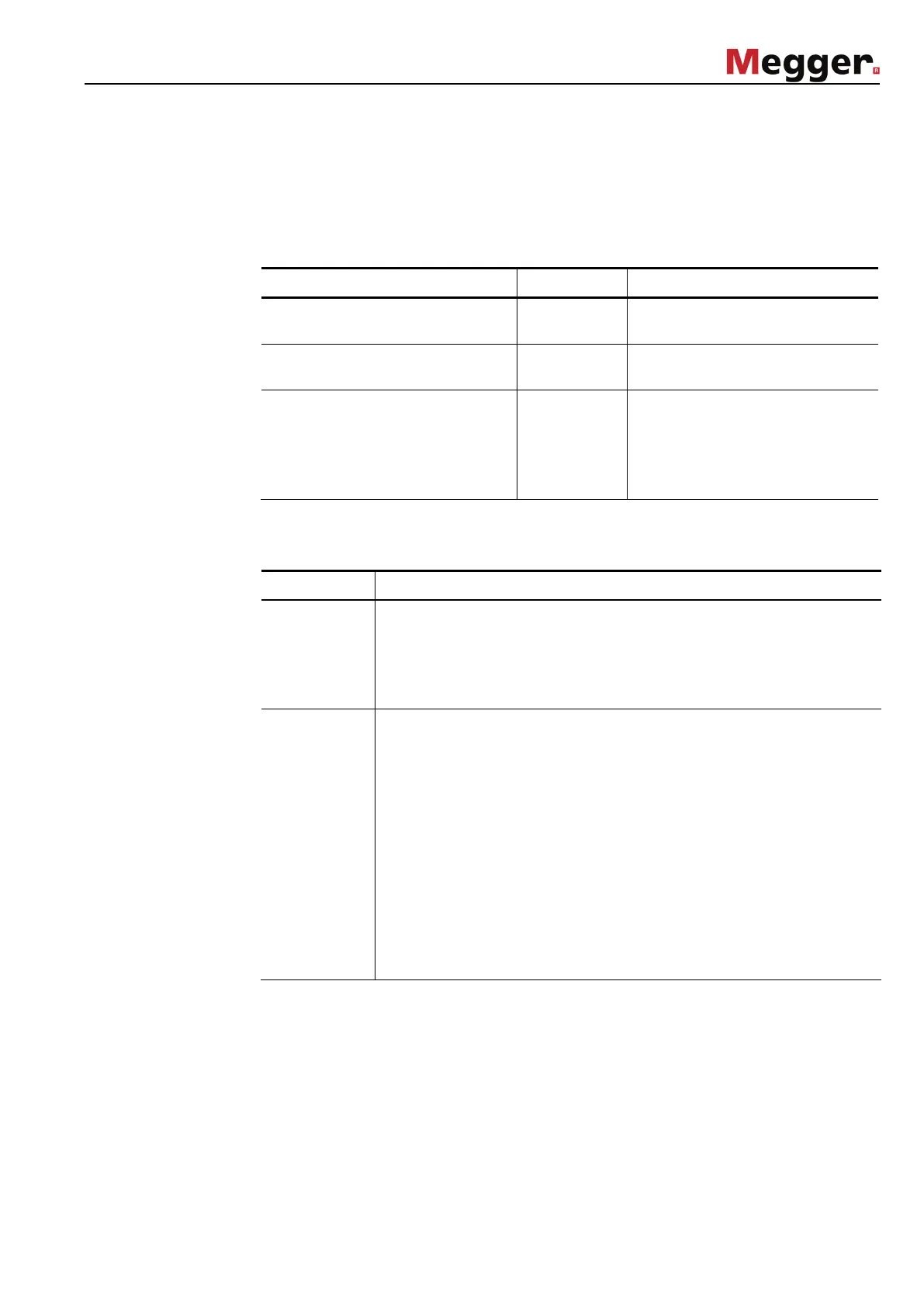

The following table provides some generally accepted test parameters for different

applications:

Application Test voltage Test duration in minutes

VLF test on cables with extruded

insulation

3Uo 30 … 60

DC test on PILC (Paper Insulated

Lead Covered) cables

8Uo 15

Sheath test on…

… PVC cables

… medium voltage PE cables

… high voltage PE cables

3 kV

5 kV

10 kV

5

5

1

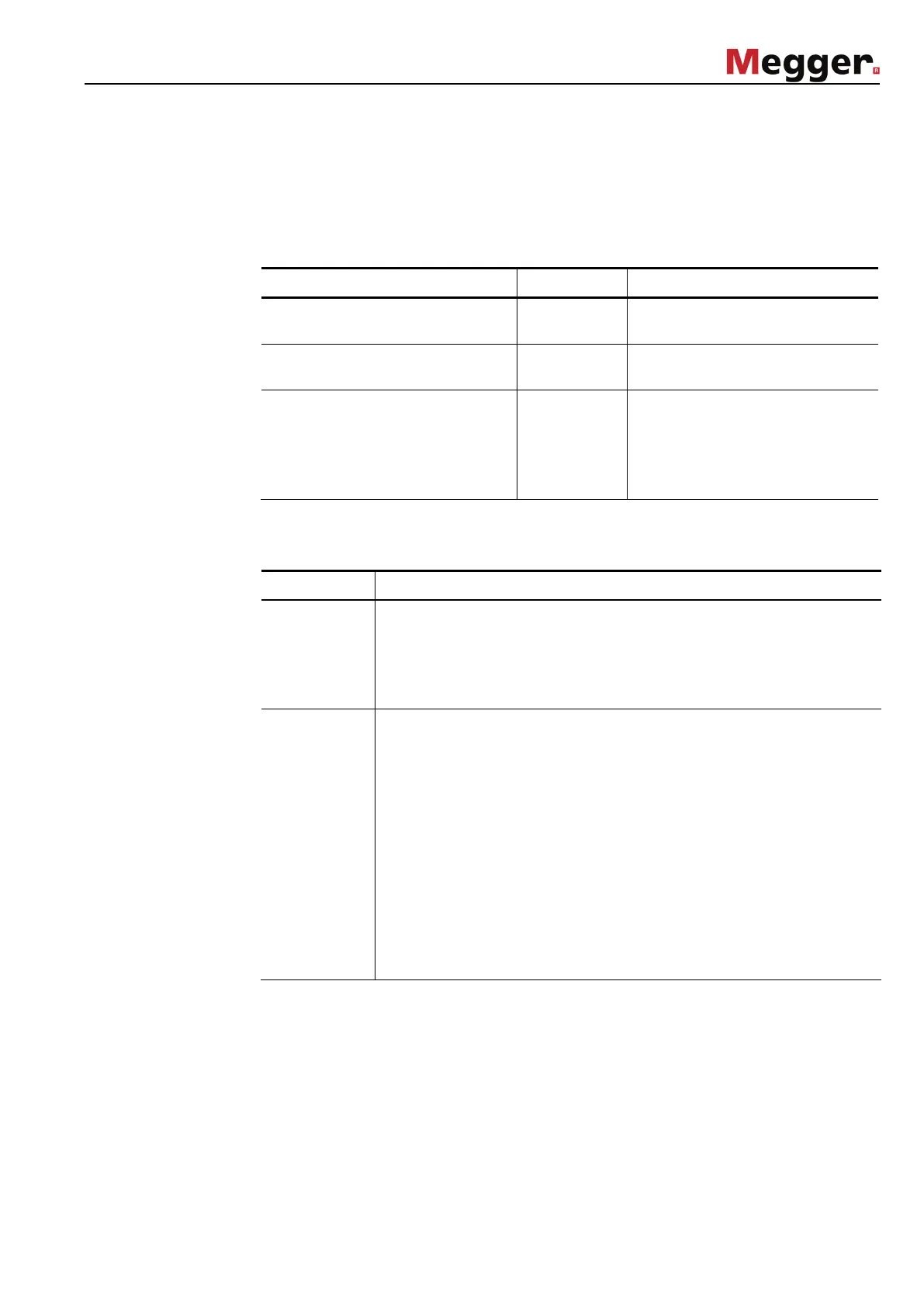

Adapting the test

parameters

To adjust the test settings, select Test setup from the settings menu (see section 4.1).

The amount of adjustable test parameters differs between the different operation modes.

Menu item Description

Test voltage The test voltage can be set in increments of 0.1 kV.

For sheath test and pinpointing, the selected value represents the

initial voltage level which can still be cautiously increased up to the

voltage threshold specified under Range (see next page) during

operation.

Test

frequency

For the modes “VLF Sinus” and “VLF Rectangle”, the test frequency

can be set in increments of 0.01 Hz between 0.01 Hz and 0.1 Hz.

Alternatively, automatic frequency calculation (auto

activated.

At the start of a voltage test, automatic load recognition is conducted.

Since the maximum permitted test frequency depends on the

determined cable capacitance and the set test voltage (see

section 2.3), it can happen that the test cannot be performed with the

set but with a decreased frequency.

If test frequency is set to auto, the switch to the lower frequency is

automatically performed. But if the parameter is set to a fixed value,

the system prepares for a switch to the highest possible frequency

which requires the confirmation of the user (20 second timeout).

Loading...

Loading...