IMO-R23EN 3

1 GENERAL

1.1 Scope of the Manual

This instruction manual contains important information

regarding the installation, maintenance and

troubleshooting of Jamesbury® 1/2" – 2" (DN 15 – 50)

Standard Bore Series 7000RR and the 1/2" – 1-1/2" (DN 15

– 40) Full Bore Series 9000RR Flanged Ball Valves for

railroad service. Please read the instructions carefully and

save them for future reference.

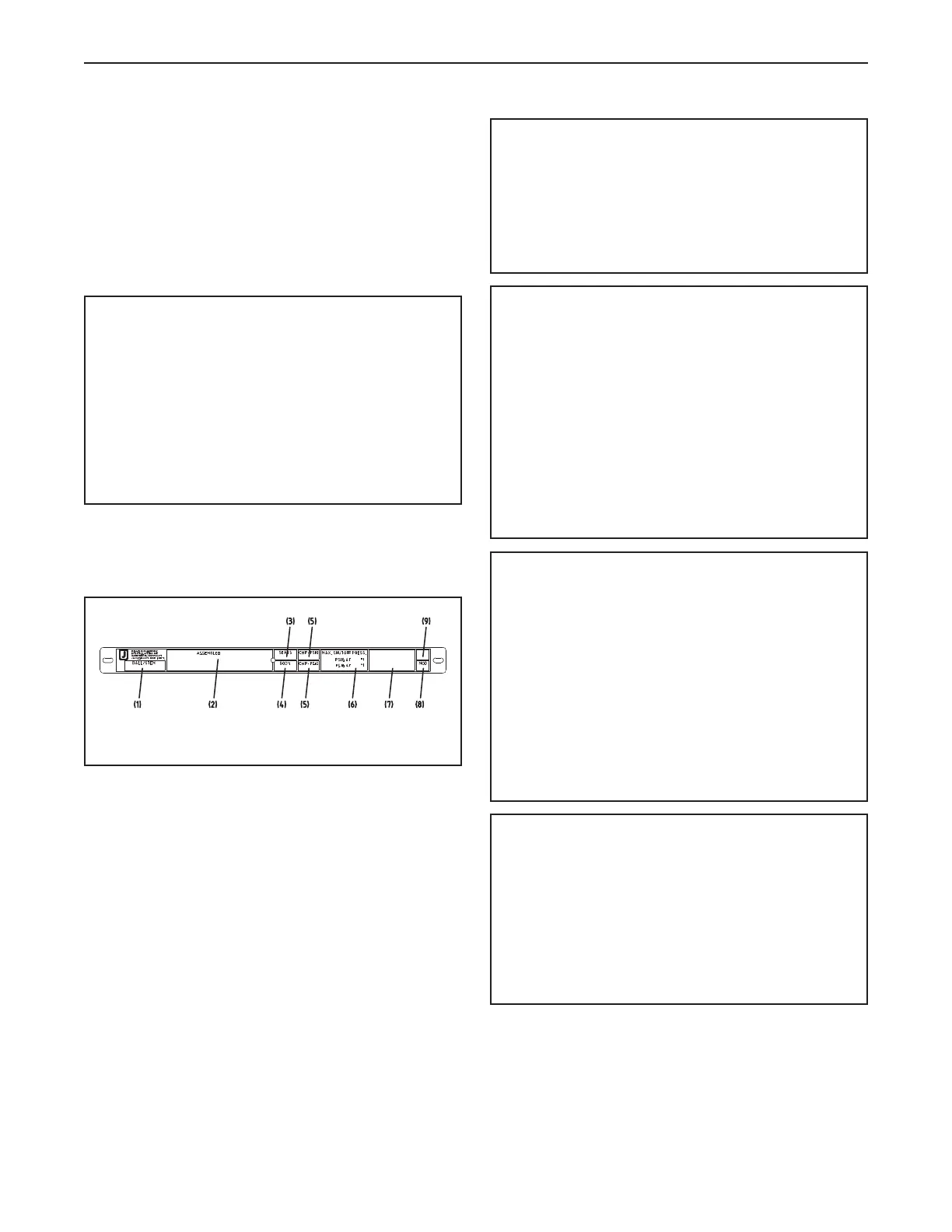

1.2 Valve Markings

The valve has an identification plate attached to the

pipeline flange (See Figure 1).

Identification plate markings:

1. Ball/Stem material

2. Valve catalog code

3. Seat Material

4. Body Material

5. Maximum operating pressure

6. Maximum/minimum shut-off pressure/temperature

7. Approvals/Special Service marking

8. Model

9. Assembly date

1.3 Safety Precautions

WARNING:

AS THE USE OF THE VALVE IS APPLICATION SPECIFIC, A NUMBER OF

FACTORS SHOULD BE TAKEN INTO ACCOUNT WHEN SELECTING A

VALVE FOR A GIVEN APPLICATION. THEREFORE, SOME OF THE

SITUATIONS IN WHICH THE VALVES ARE USED ARE OUTSIDE THE

SCOPE OF THIS MANUAL.

IF YOU HAVE ANY QUESTIONS CONCERNING THE USE, APPLICATION

OR COMPATIBILITY OF THE VALVE WITH THE INTENDED SERVICE,

CONTACT METSO FOR MORE INFORMATION.

Figure 1 Identification plate

WARNING:

DO NOT EXCEED THE VALVE PERFORMANCE LIMITATIONS!

EXCEEDING THE PRESSURE OR TEMPERATURE LIMITATIONS

MARKED ON THE VALVE IDENTIFICATION PLATE MAY CAUSE

DAMAGE AND LEAD TO UNCONTROLLED PRESSURE RELEASE.

DAMAGE OR PERSONAL INJURY MAY RESULT.

WARNING:

SEAT AND BODY RATINGS!

THE PRACTICAL AND SAFE USE OF THIS PRODUCT IS DETERMINED

BY BOTH THE SEAT AND BODY RATINGS. READ THE

IDENTIFICATION PLATE AND CHECK BOTH RATINGS. THIS

PRODUCT IS AVAILABLE WITH A VARIETY OF SEAT MATERIALS.

SOME OF THE SEAT MATERIALS HAVE PRESSURE RATINGS THAT

ARE LESS THAN THE BODY RATINGS. ALL OF THE BODY AND SEAT

RATINGS ARE DEPENDENT ON VALVE TYPE AND SIZE, SEAT

MATERIAL, AND TEMPERATURE. DO NOT EXCEED THESE

RATINGS!

WARNING:

BEWARE OF BALL MOVEMENT!

KEEP HANDS, OTHER PARTS OF THE BODY, TOOLS AND OTHER

OBJECTS OUT OF THE OPEN FLOW PORT. LEAVE NO FOREIGN

OBJECTS INSIDE THE TANK CAR. WHEN THE VALVE IS ACTUATED,

THE BALL FUNCTIONS AS A CUTTING DEVICE. DISCONNECT ANY

PNEUMATIC SUPPLY LINES, ANY ELECTRICAL POWER SOURCES

AND MAKE SURE SPRINGS IN SPRINGRETURN ACTUATORS ARE IN

THE FULL EXTENDED/RELAXED STATE BEFORE PERFORMING ANY

VALVE MAINTENANCE. FAILURE TO DO THIS MAY RESULT IN

DAMAGE OR PERSONAL INJURY!

WARNING:

WHEN HANDLING THE VALVE OR VALVE/ACTUATOR

ASSEMBLY, TAKE ITS WEIGHT INTO ACCOUNT!

NEVER LIFT THE VALVE OR VALVE/ACTUATOR ASSEMBLY BY THE

ACTUATOR, POSITIONED, LIMIT SWITCH OR THE PIPING. PLACE

THE LIFTING DEVICES SECURELY AROUND THE VALVE BODY.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

DAMAGE OR PERSONAL INJURY FROM FALLING PARTS.

Loading...

Loading...