Slurry Pump

WH15AM1AAA0EN_06B.DOC JAN 05-W02

Installation

7/8

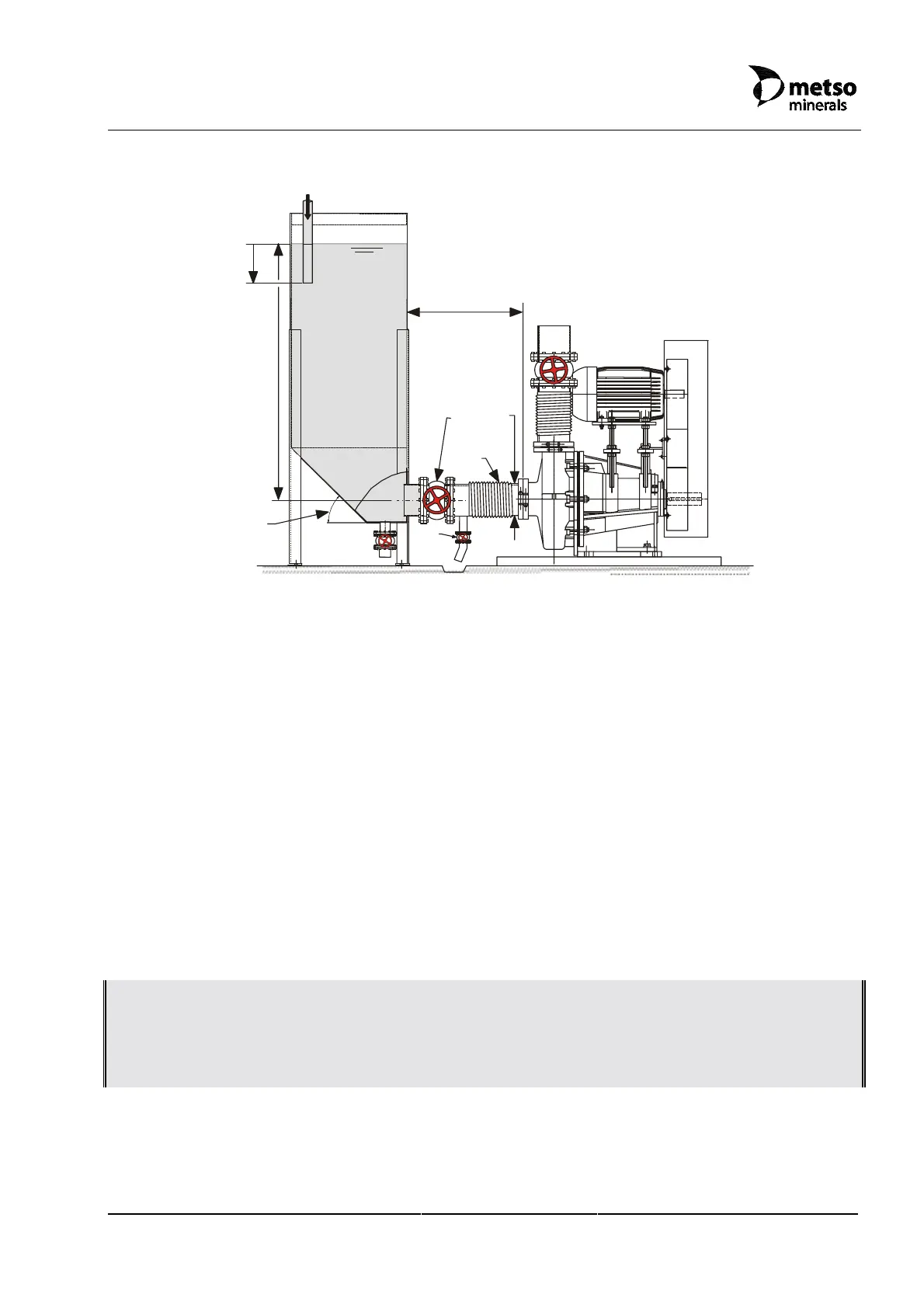

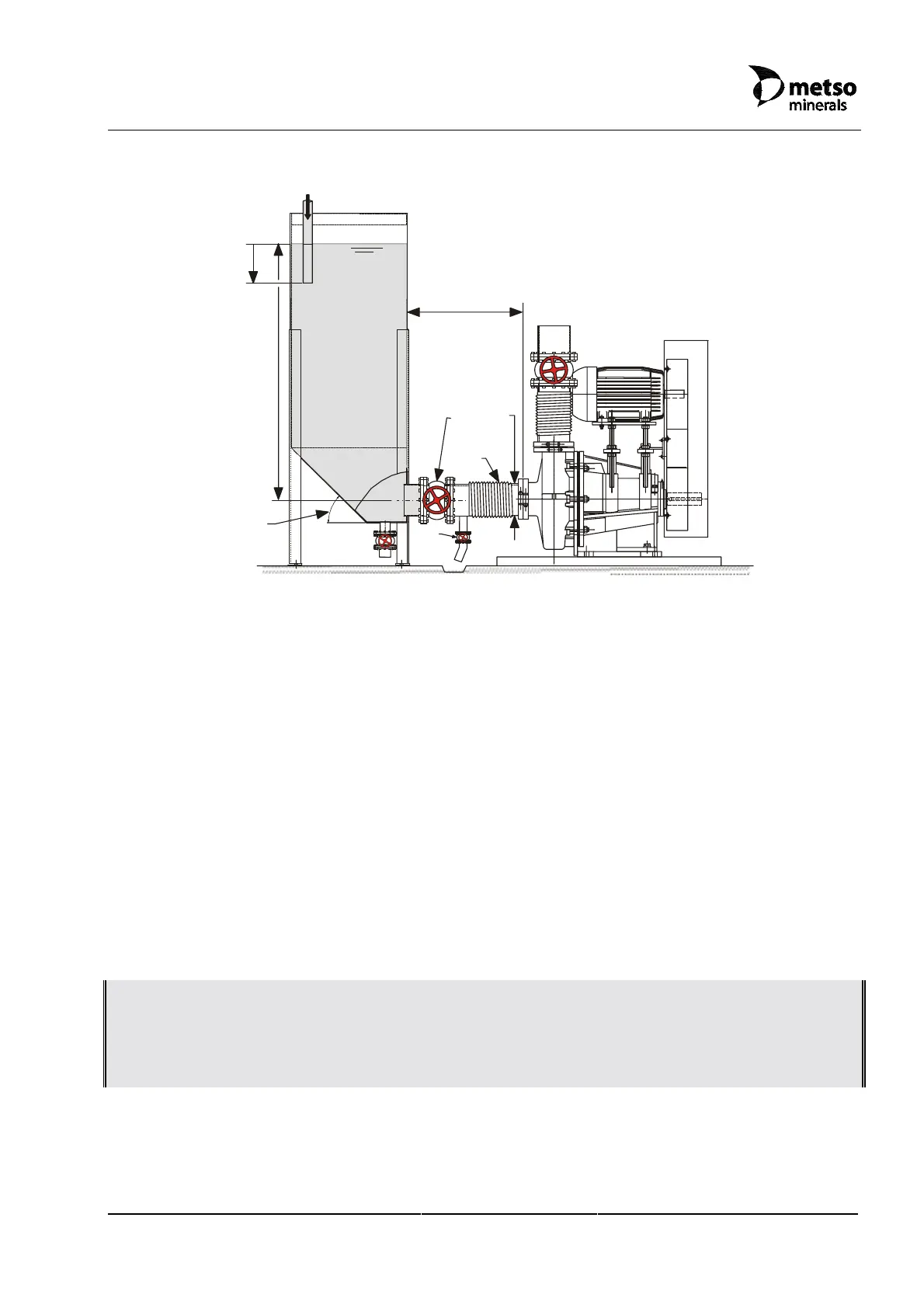

45º-60º

D

L

V(m )

3

15s V/Q 2min

<<

Q(m /s)

3

(4 × D) L (10 × D)

<<

d

F

S

h

H

Figure 6.5-1 Recommendations for pipework layout

The pump is NOT self-priming, which means that the pump case must be full of liquid

before the pump is started. Additionally, take note of the following (see also Figure 6.5-1):

• Sump bottom should have an angle of 45º. Fast settling particles may require up to

60º.

• Sump feed (h) should be below the sump liquid surface to avoid air entrainment.

Allowing the pump to draw air will drastically reduce the useful life of the hydraulic

parts.

• Sump volume should be as small as possible. Slurry ‘Retention Time’ is the relevant

parameter for determining the size of the sump. It ranges between 15 seconds and 2

minutes for slurries containing coarse particles and fine particles, respectively.

• Separate sumps are preferred for standby pump installations. This will avoid settling

out in the standby pump when not in use.

• For slurry applications, ensure a steady, uniform feed to the pump, where practicable.

• Install the pump as close as possible to the sump.

• Keep the length of suction pipe and the number of bends in the pipework to the

minimum practicable. Use reinforced flexi-pipes (F) to connect to inlet and outlet.

NOTE: INLET PIPE SHOULD, HOWEVER, HAVE A STRAIGHT LENGTH (L), AT LEAST, 4 TIMES ITS

DIAMETER TO ENSURE FAVOURABLE FLOW CONDITIONS INTO THE PUMP. IF A VALVE (S) IS

FITTED ON THE INLET SIDE, IT MUST BE FULLY OPEN WHEN THE PUMP IS RUNNING AND

SHOULD HAVE A STRAIGHT FLOW PATH OF THE SAME AREA AS THE CONNECTED PIPE.

SUCTION PIPES WHICH ARE LONGER THAN 10 TIMES THE DIAMETER SHOULD BE AVOIDED.

• Sump level (H) should be 6 times pump inlet diameter (D) when measured from the

centre line of pump.

• The diameter of the inlet pipe should be the same as, or larger than, the pump inlet

diameter.

Loading...

Loading...