Slurry Pump

WH16AM1TAA0EN_02A.DOC JAN 04-W51

Care and maintenance

1/6

9 CARE AND MAINTENANCE

9.1 Safety measures

WARNINGS

ISOLATE THE PUMP FROM ALL SOURCES OF ELECTRICITY AND POWER, BEFORE COMMENCING ANY

MAINTENANCE WORK.

ALWAYS ASCERTAIN THE NATURE OF THE PROCESS LIQUID BEFORE COMMENCING WORK ON A

PUMP AND FOLLOW THE HEALTH AND SAFETY PROCEDURES RELEVANT TO THE PROCESS LIQUID. IT

MAY BE HARMFUL TO HEALTH.

Should the process liquid be of a harmful or hazardous nature take the following

precautions as a minimum;

1. always use protective goggles and rubber gloves;

2. flush the pump thoroughly with clean water, before opening the pump;

3. after removing the components, flush them thoroughly with clean water.

4. follow the health and safety instructions provided in section 3.

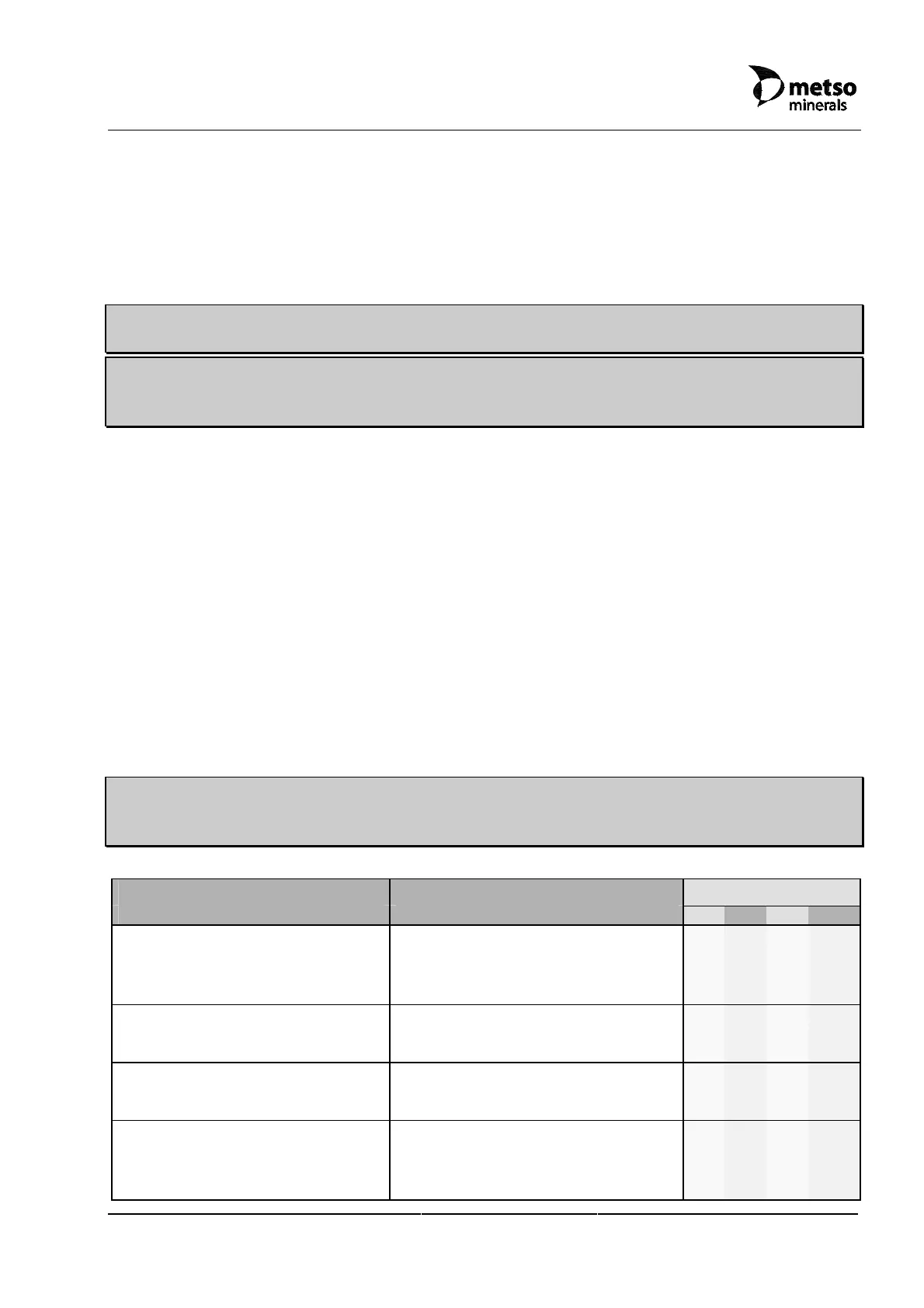

9.2 Preventive maintenance & service schedule

9.2.1

Routine maintenance

Use the maintenance schedule below as a basis from which to produce a schedule

suitable to each pumping application after experience in operation has been gained.

WARNING

BEFORE CARRYING OUT ANY MAINTENANCE ENSURE THAT ALL ELECTRICAL SUPPLIES TO THE

MOTOR AND ASSOCIATED EQUIPMENT ARE SWITCHED OFF AND ISOLATED. LOCK IN THE OFF

POSITION OR ATTACH SUITABLE WARNING PLATES TO THE RELEVANT SWITCHES.

ITEM ACTION

RUNNING HOURS

10 100 250 1000

Pump Case, Bearing Cylinder

Housing and Gland Area

Pipework

Keep all areas clean and free

from debris, slurry etc.

×

Hydraulic cylinders (where

applicable)

Check for oil leaks. Rectify, as

required.

×

Inlet/Outlet Connections Check for security and leaks.

Rectify as required.

×

Gland Seal - General Check for leaks. Tighten gland

follower screws or renew seal as

necessary.

×

Loading...

Loading...