Slurry Pump

WH06AAAAAA0EN_02B.DOC JAN 04-W07

Description

3/4

2.2 Applications

The Metso Minerals Slurry Pump has been designed for a wide variety of abrasive

pumping duties. While the pumps may be used in many different industries, they are all

designed for constant use in the most arduous conditions. These high-efficiency pumps

are of a simple design, providing ease of maintenance and facilitating replacement of

wearing parts.

2.3 Design

2.3.1

General

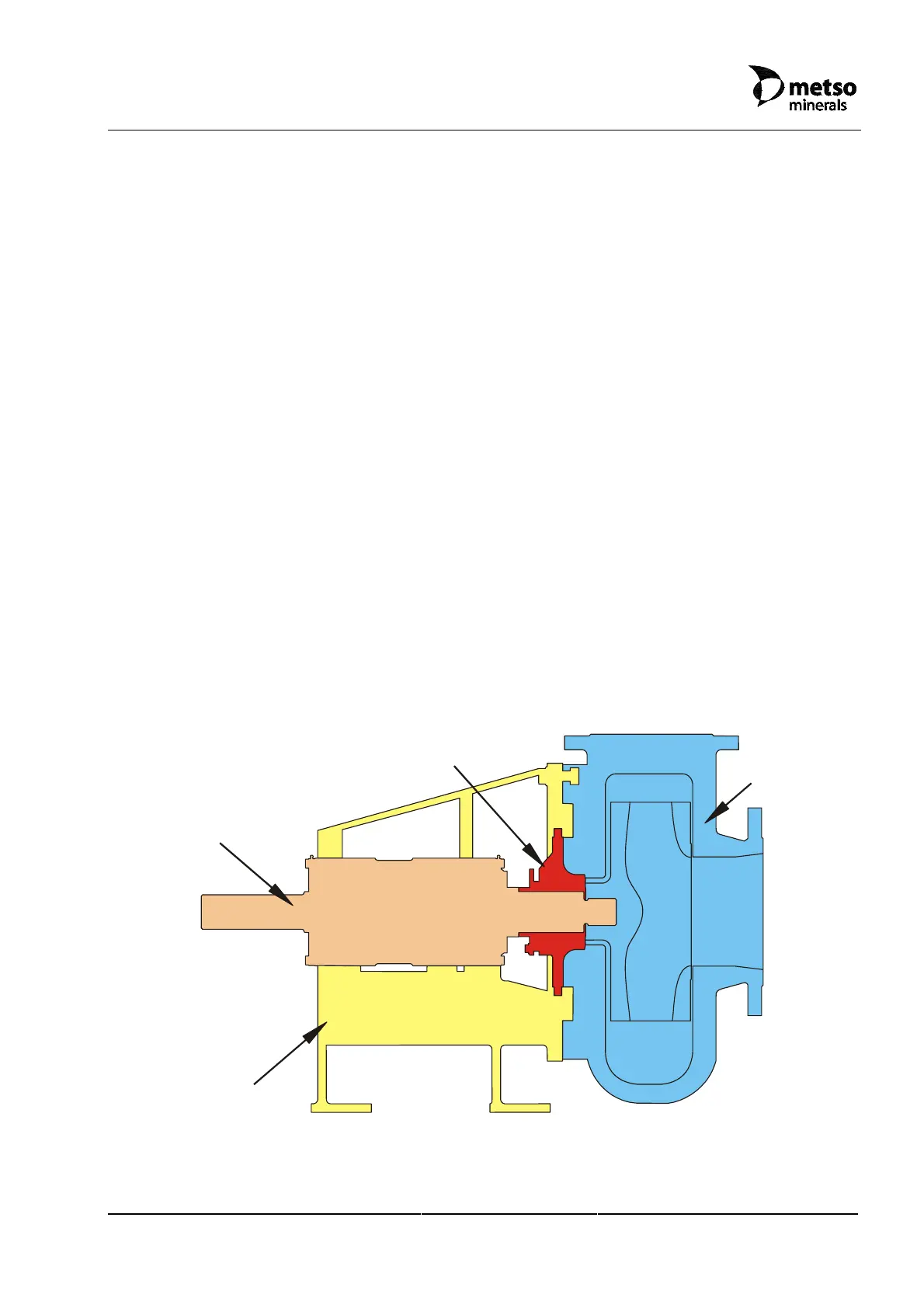

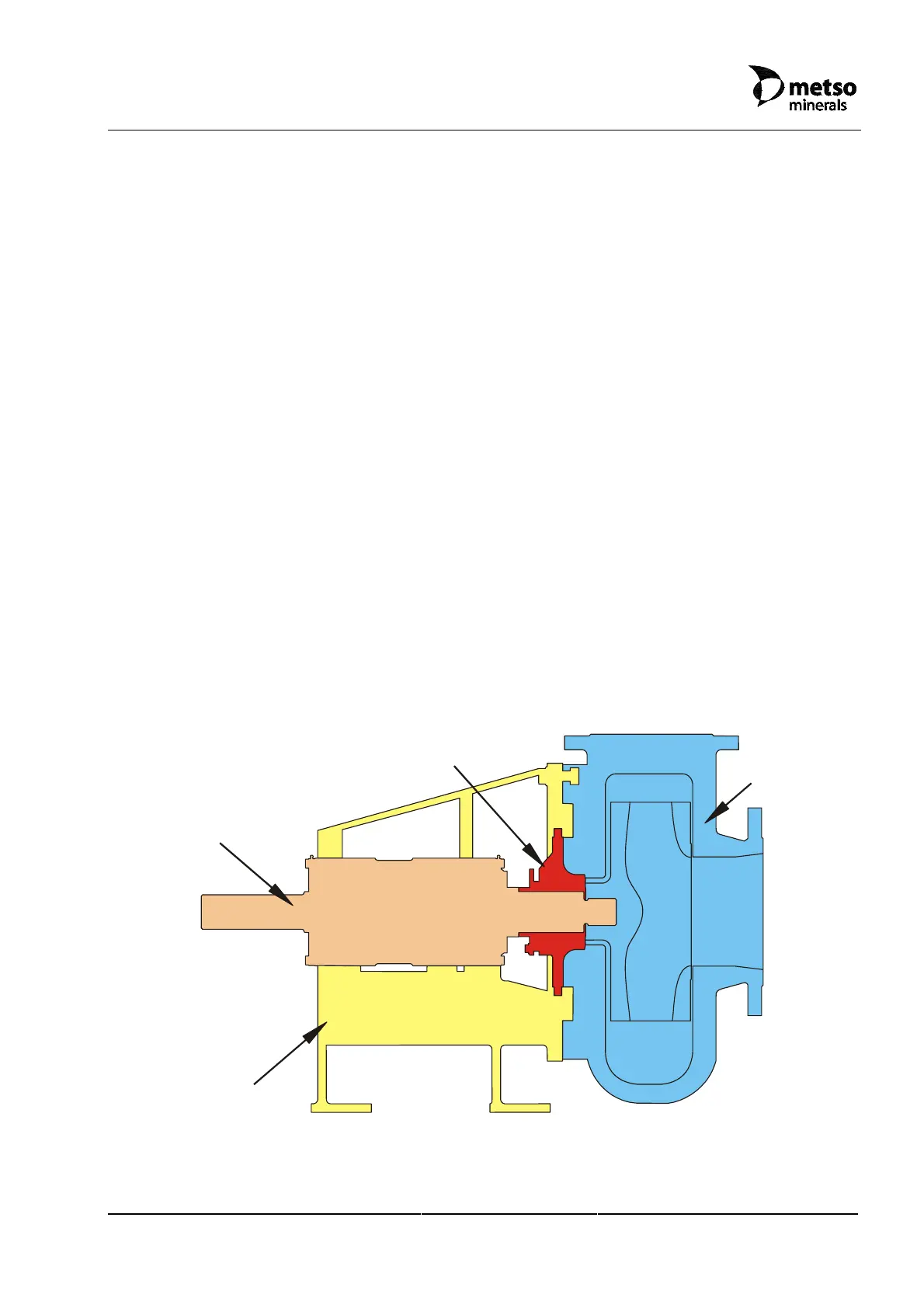

Slurry Pumps are made up of four basic modules, the frame (A), the bearing cylinder (B),

the shaft seal (C) and the wet-end (D) assemblies – see Figure 2.3.1-1.

A comprehensive range of modules are available, to configure pumps to suit a wide range

of applications.

Pumps are supplied bareshaft or as fixed-base pumpsets with various choices of motor

mounting position. Manual or hydraulic slide-bases are optional.

Maximum efficiency is maintained by setting impeller running clearance(s). The adjustment

is easily carried out during maintenance and shut-down periods.

Standard bearing cylinders are grease lubricated, but oil lubricated bearings are an option.

Pump designation is made up of letters which identify the range and numbers which

indicate the inlet diameter in millimetres –e.g. HM150.

A

B

C

D

Figure 2.3.1-1 Typical outline design of Metso Minerals Slurry Pumps showing the basic

pump modules: Frame (A), Bearing cylinder(B), Shaft seal(C), Wet-end (D)

Loading...

Loading...