Slurry Pump

WH16AM1TAA0EN_02A.DOC JAN 04-W51

Care and maintenance

2/6

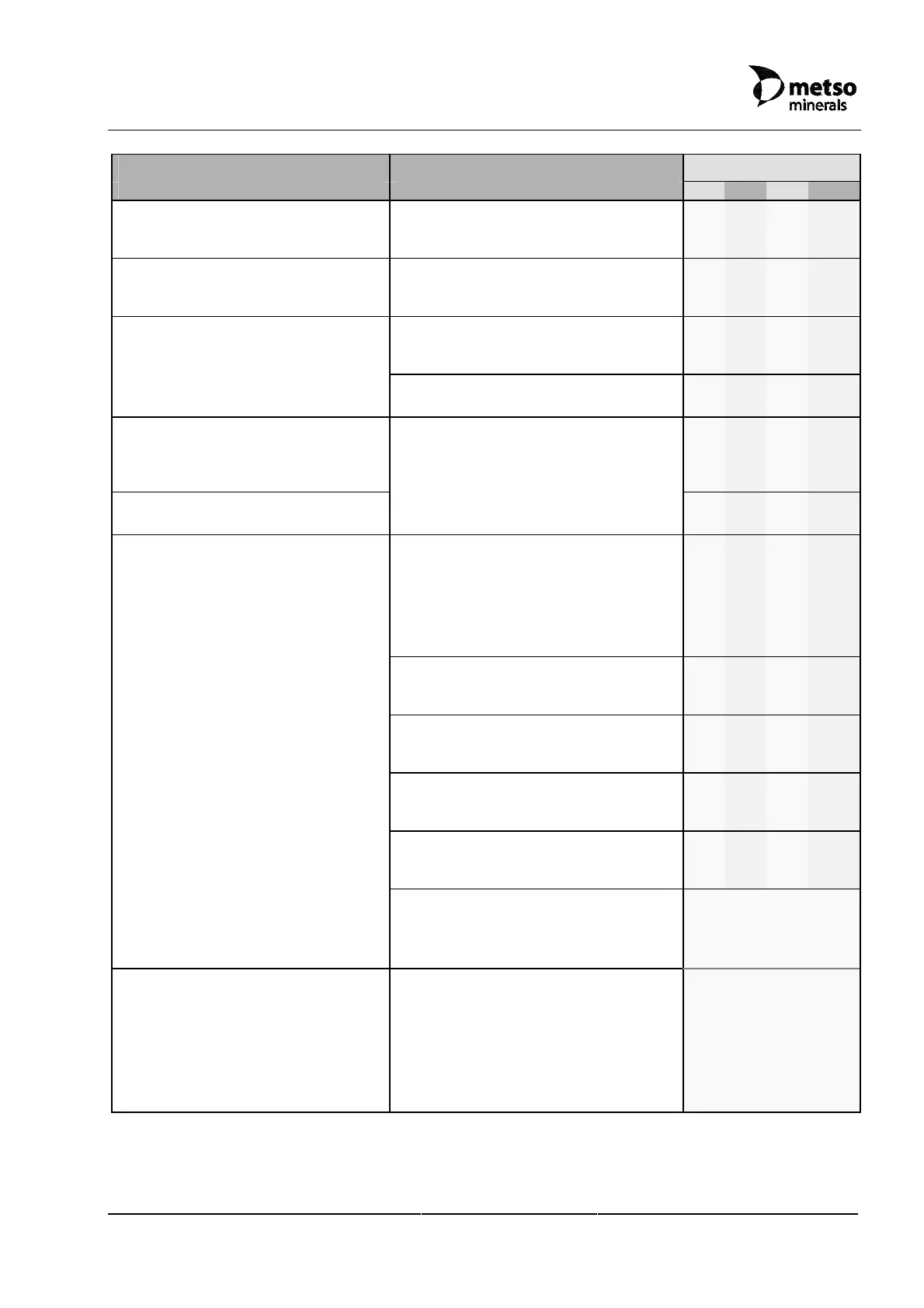

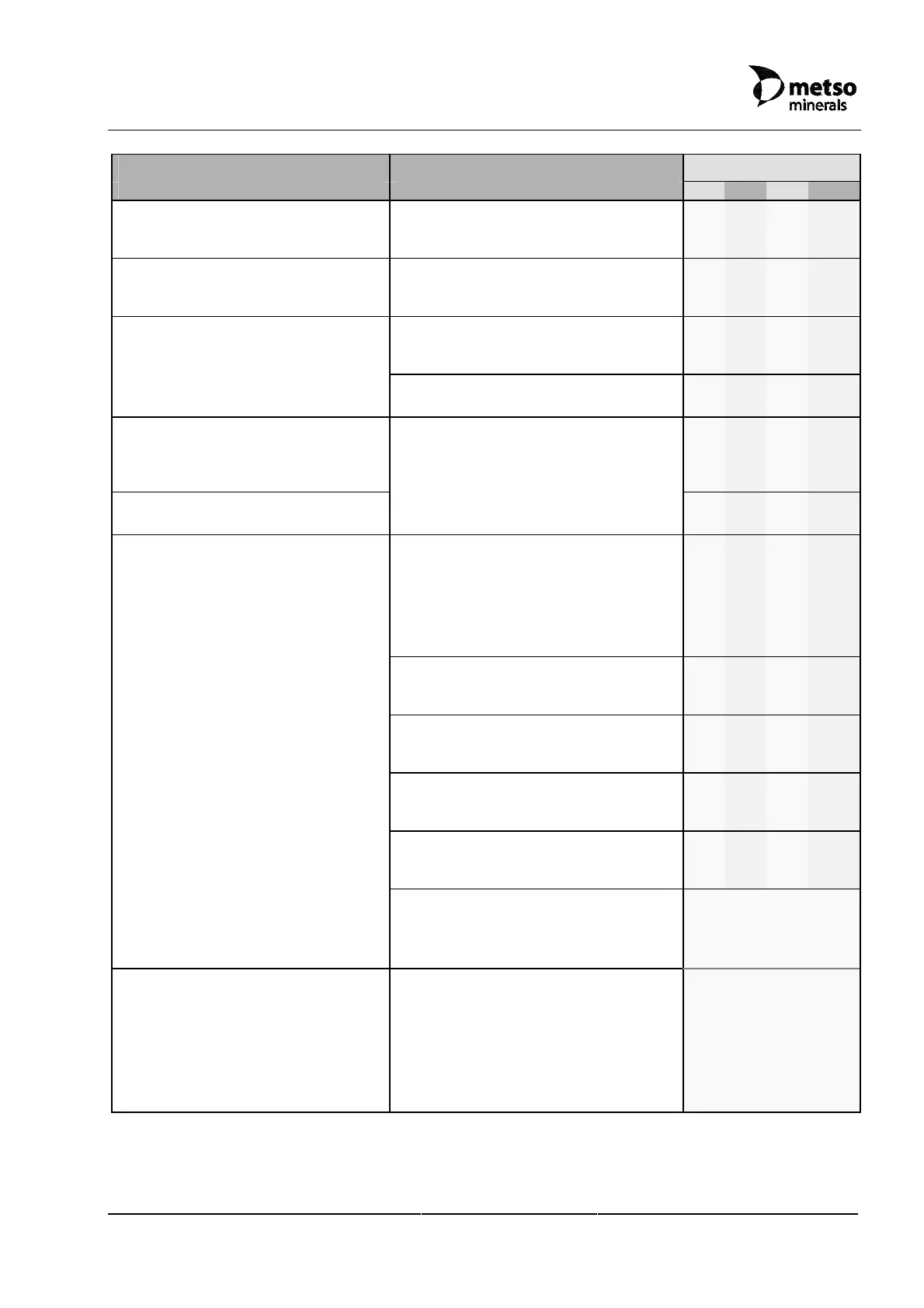

ITEM ACTION

RUNNING HOURS

10 100 250 1000

Water flushing gland seal. Check stuffing box connection for

leaks. Rectify as necessary.

×

Centrifugal Gland Seal Tighten gland follower screws or

renew seal as necessary.

×

Bearing Cylinder

Lubricate bearings. See section

9.4.

×

Check Bearings for overheating.

×

All fixings

Ensure attachments are secure.

Tighten to correct torque as

necessary.

×

Adjusting Screw Locknut (P38)

See Torque Table, Section 11.1.

×

Inspect Drive Belts, if fitted, for

deterioration and damage.

Replace as necessary. Check

drive belt tension and adjust as

necessary.

×

Check drive couplings, if fitted, for

security of connection.

×

Pump/Drive unit installation Check safety covers for security

of attachment - important

×

Check drive motor holding down

bolts for security of attachment.

×

Keep drive motor clean and free

from debris, slurry etc.

×

Service Drive Motor as

necessary.

In accordance with

manufacturer’s

instructions.

Pump impeller Check axial clearance after run-in

period. Adjust clearance by

shimming. Refer to Setting Pump

Clearances, sub-section 9.5.1.

After first 100

running hours and

repeat at intervals

equal to 25% of the

anticipated life of

the pump.

Loading...

Loading...